Combined desalination wastewater treatment system for synchronous recovery of salt differential energy and chemical energy in wastewater

A waste water treatment system, salt difference energy technology, applied in the field of joint desalination waste water treatment system, can solve the problems of difficult collection of products, waste of chemical energy, waste of water resources, etc., achieve high economic and social benefits, reduce the use of fresh water resources, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

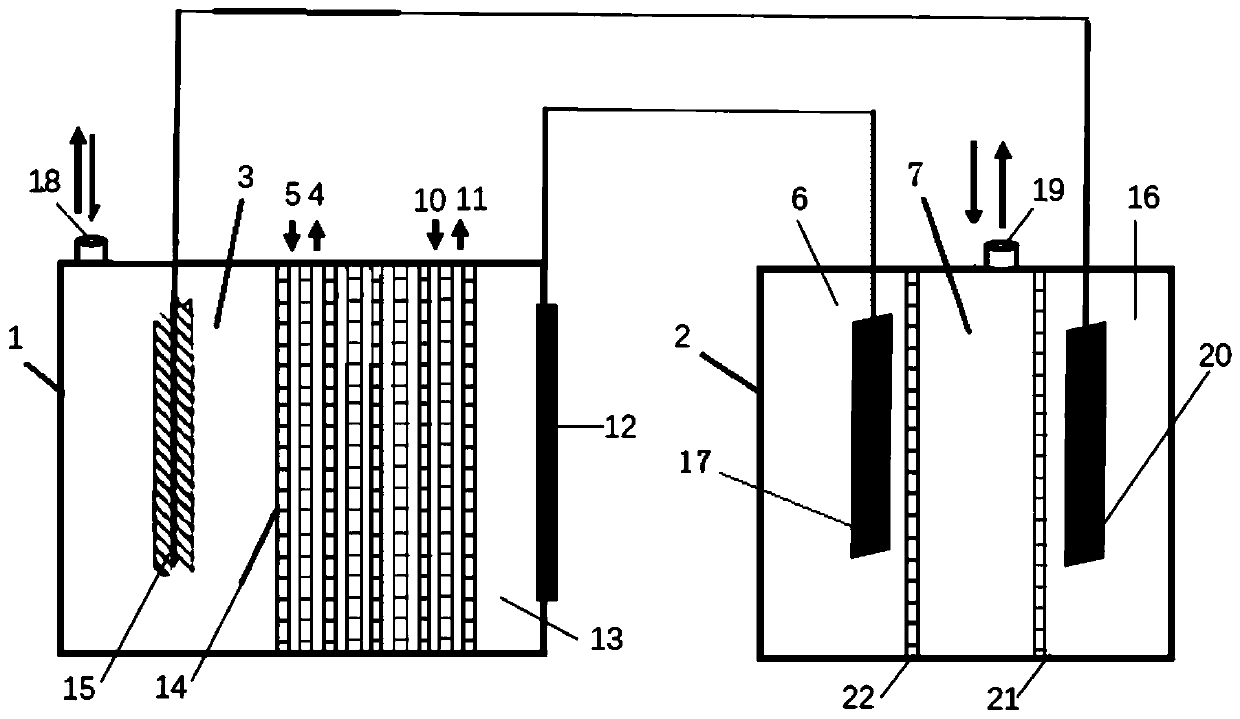

[0028] see Figure 1 to Figure 4 , a combined desalination wastewater treatment system for synchronous recovery of salinity energy and chemical energy in sewage, consisting of a microbial reverse electrodialysis pool 1 and an electrodialysis pool 2.

[0029] The microbial reverse electrodialysis cell 1 is used to recover the salt difference energy between the high-concentration saline wastewater HC and the low-concentration saline fresh water LC and the chemical energy of organic matter in the high-concentration saline wastewater, and generate electricity.

[0030] The electrodialysis cell 2 is used to desalinate high-salt wastewater by using the electric energy generated by the microbial reverse electrodialysis cell 1 .

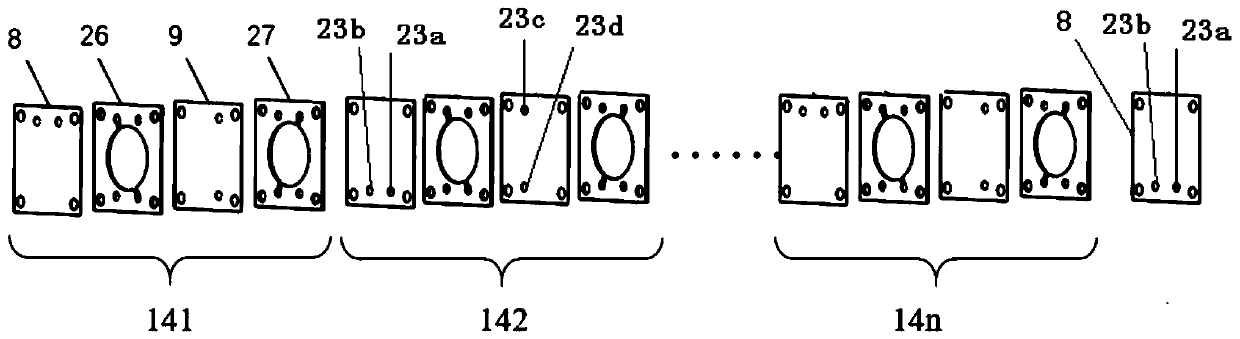

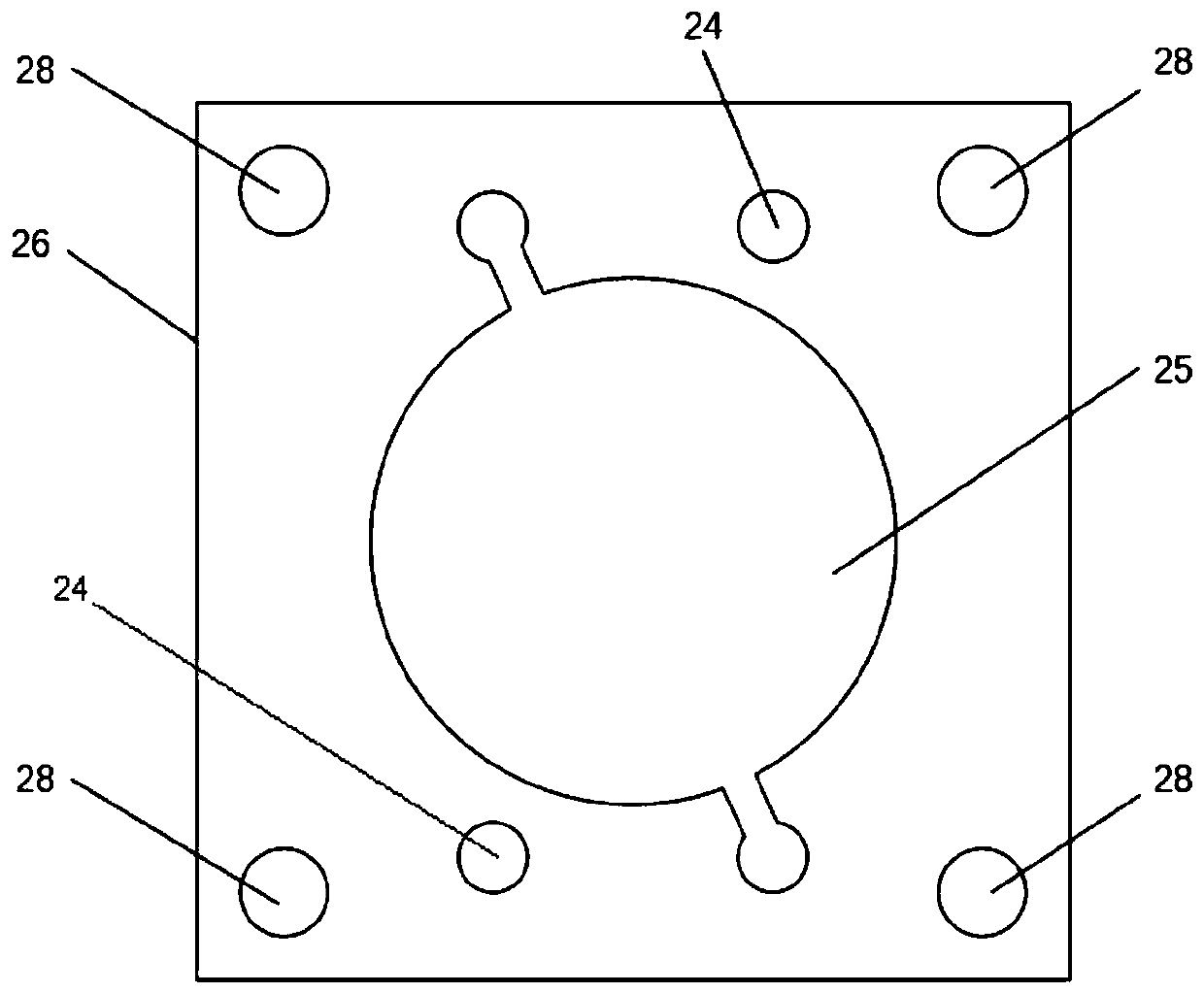

[0031] The microbial reverse electrodialysis cell comprises an anode chamber 3 and a cathode chamber 13, and the anode chamber 3 and the cathode chamber 13 are separated by a membrane group 14; an anode carbon brush 15 is arranged in the anode chamber 3, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com