Graphite purification wastewater treatment process and neutralizing device applied to process

A waste water and pumping pipe technology, applied in the direction of neutralization water/sewage treatment, etc., can solve the problems of unreacted waste water and the inability to mix waste water, etc., and achieve the effect of fast mixing and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

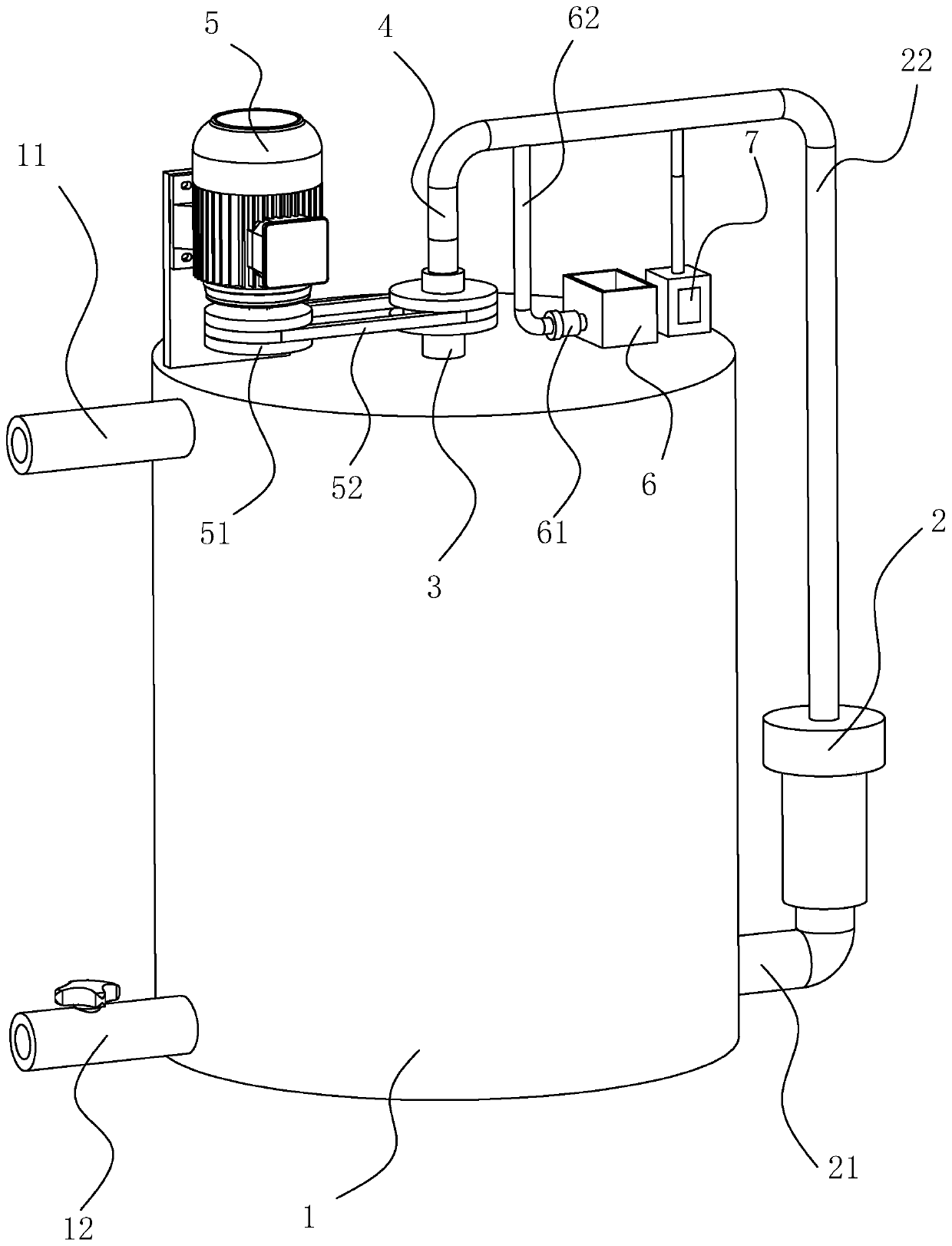

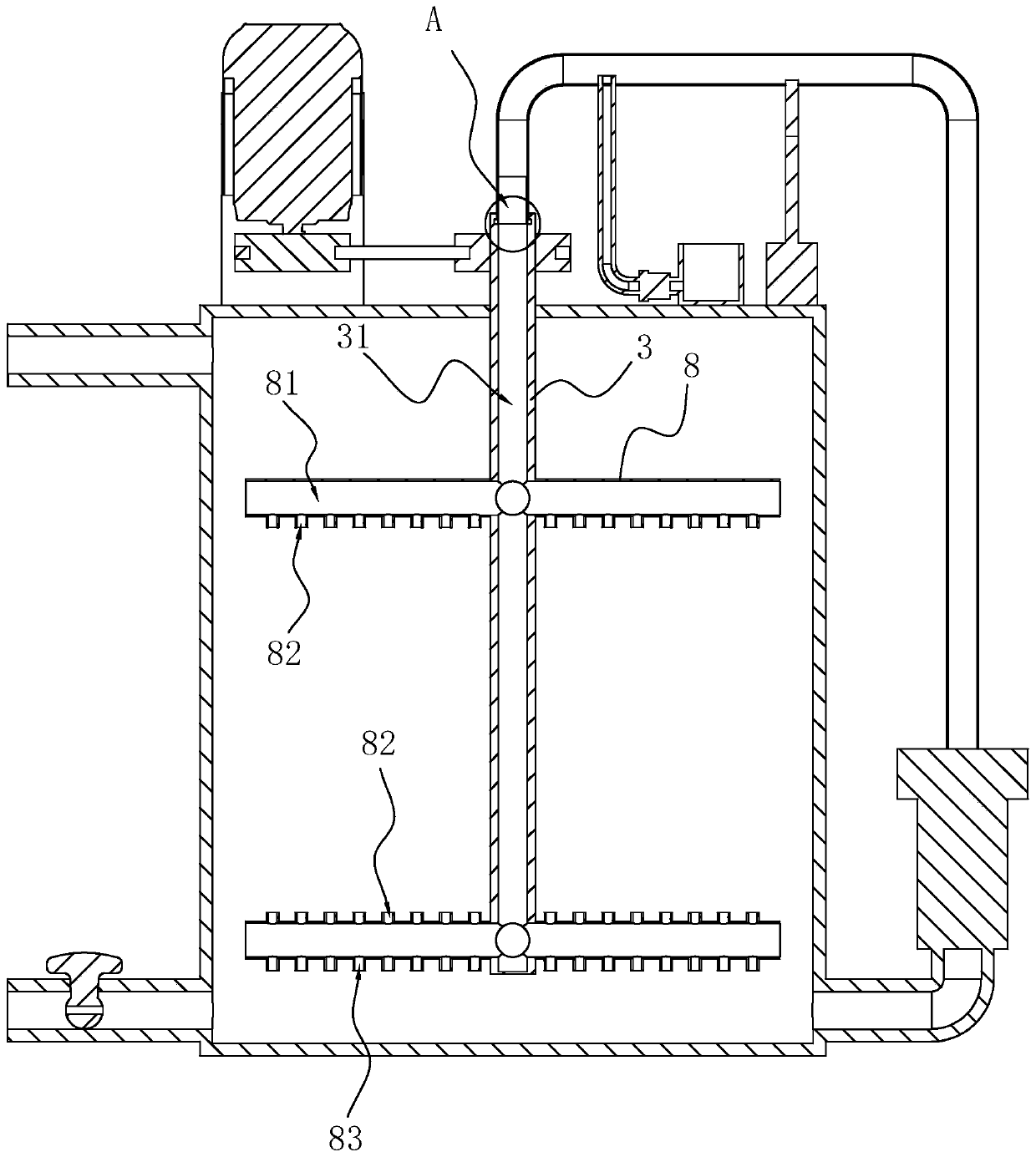

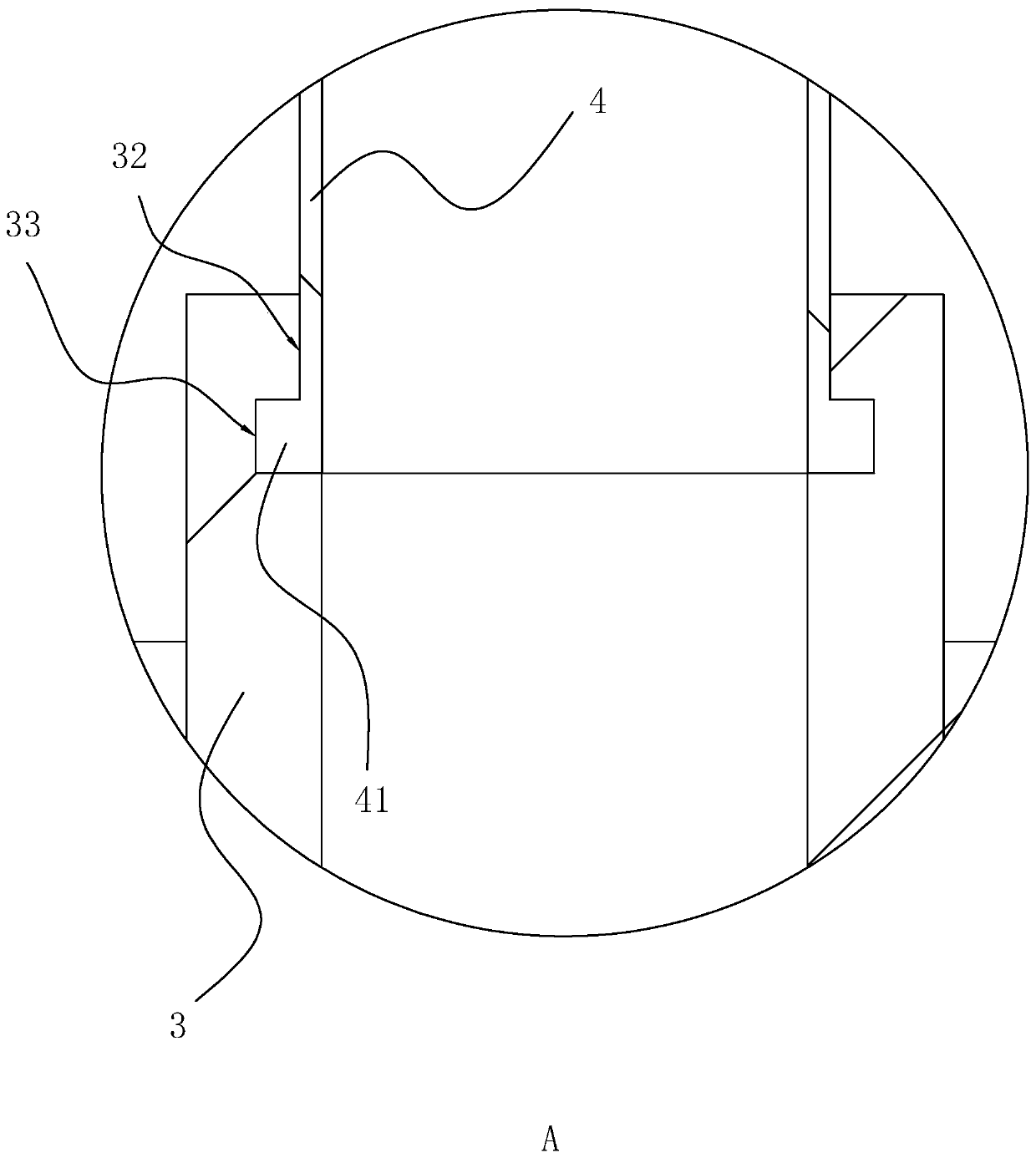

[0038] Embodiment one: a kind of neutralization device, see attached figure 1 And attached figure 2, including a tank body 1, a water inlet pipe 11 fixedly connected to the side of the tank body 1 near the top, a water outlet pipe 12 fixedly connected to the side of the tank body 1 near the bottom, and a water outlet pipe 12 fixedly connected to the side of the tank body 1 away from the water outlet pipe 12 The suction pipe 21 at the bottom position, the circulation pump 2 fixedly connected to the suction pipe 21, the circulation pipe 22 fixedly connected to the circulation pump 2, the rotating shaft 3 that is rotatably connected to the top of the tank body 1 and extends into the tank body 1, The connecting pipe 4 that is arranged on the top of the rotating shaft 3 and is rotationally connected with the rotating shaft 3, the stirring paddle 8 fixedly connected on the outer periphery of the rotating shaft 3 and located in the tank body 1, and the stirring paddle 8 fixedly conn...

Embodiment 2

[0043] Embodiment two: a kind of graphite purification wastewater treatment process comprises the following steps:

[0044] a. Residue separation: the pure acid is separated from the waste water through a filter press, and the pure acid is purified and then recycled;

[0045] b. Wastewater neutralization: the separated waste water is sent into the tank body 1 through the water inlet pipe 11. When the liquid level of the waste water in the tank body 1 is higher than the suction pipe 21, the waste water in the tank body 1 is pumped out through the suction pump. When controlling the water inlet speed of the water inlet pipe 11 to be greater than the water pumping speed of the water suction pipe 21, until the water inlet is completed;

[0046] Add neutralization solution in the middle of the storage tank 6, the neutralization solution contains sodium hydroxide, lime powder and water, the weight ratio of the three is 2:3:9, and the neutralization solution is slowly sent into by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com