Production method and production system for die pressing veneer door panels

A production method and production system technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of time consumption, production line processing congestion, and occupation of main production line resources, so as to reduce the probability of sorting errors, improve work fluency, The effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

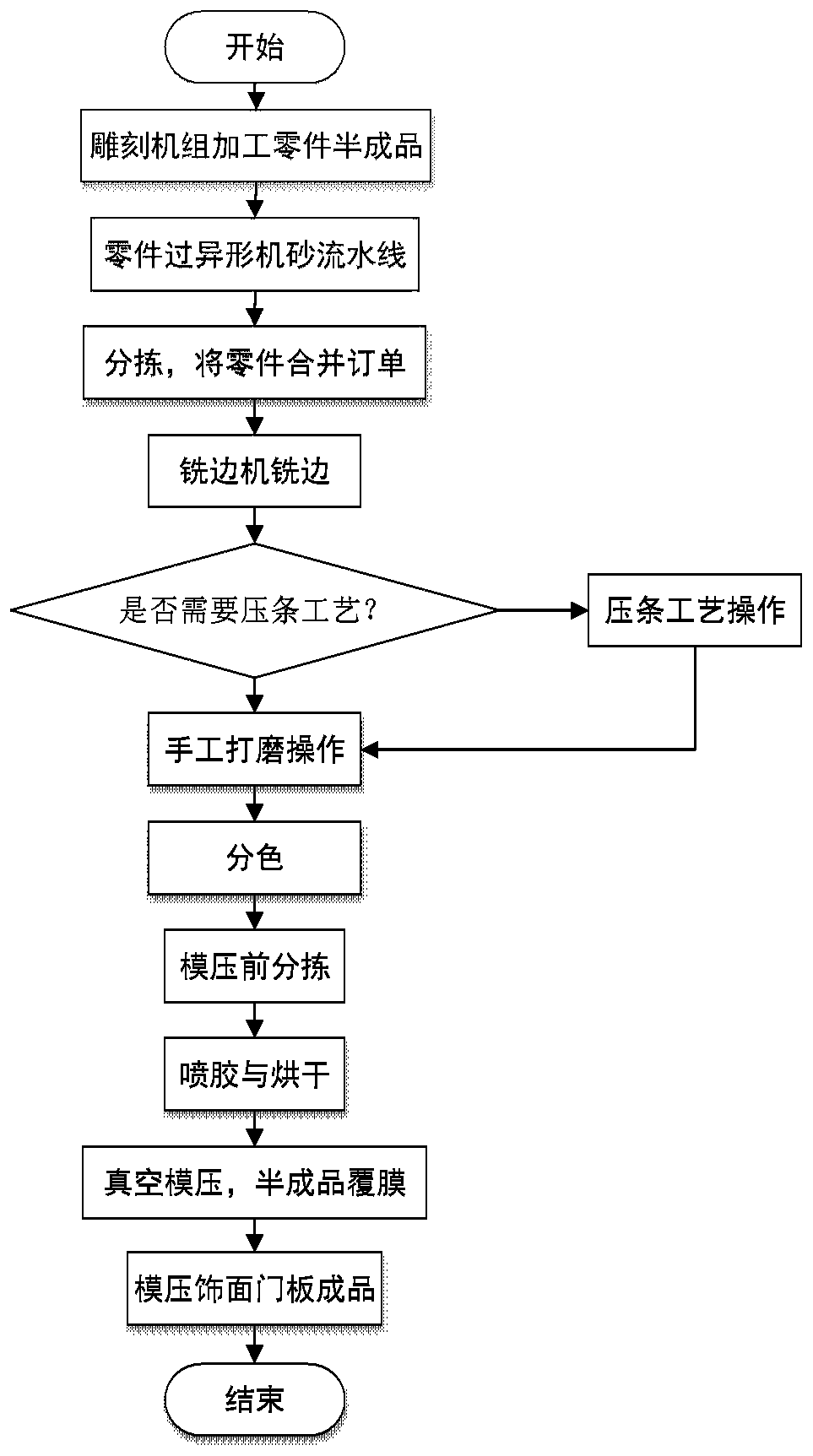

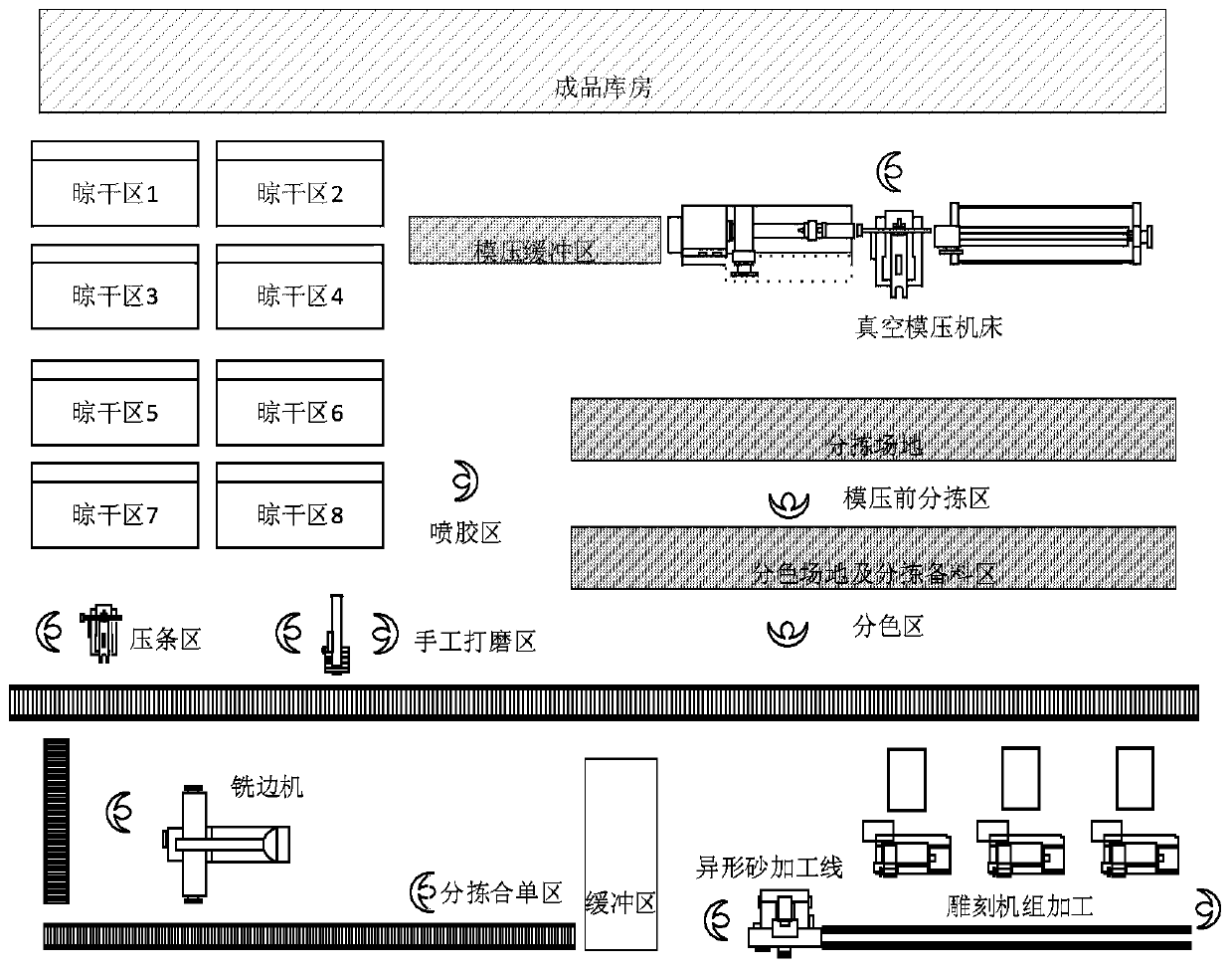

[0047] According to one aspect of the present invention, a method for producing a molded veneer door panel is provided, which includes processing the original panel into a semi-finished door panel part with hinge holes by an engraving machine, and sending it to the special-shaped machine sand assembly line to remove the semi-finished door panel part. Rough parts and burrs;

[0048] According to whether the semi-finished door panel parts need to be layered, select whether to send the semi-finished door panel parts to the layering station for layering operation;

[0049] At the color separation station, the semi-finished door panel parts are sorted according to the color to be coated, and the semi-finished door panel parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com