A metal pipe cutting device

A technology of cutting device and metal pipe fittings, applied in the direction of pipe shearing device, shearing device, accessories of shearing machine, etc. The effect of burrs and burrs, improving cutting quality, and improving heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

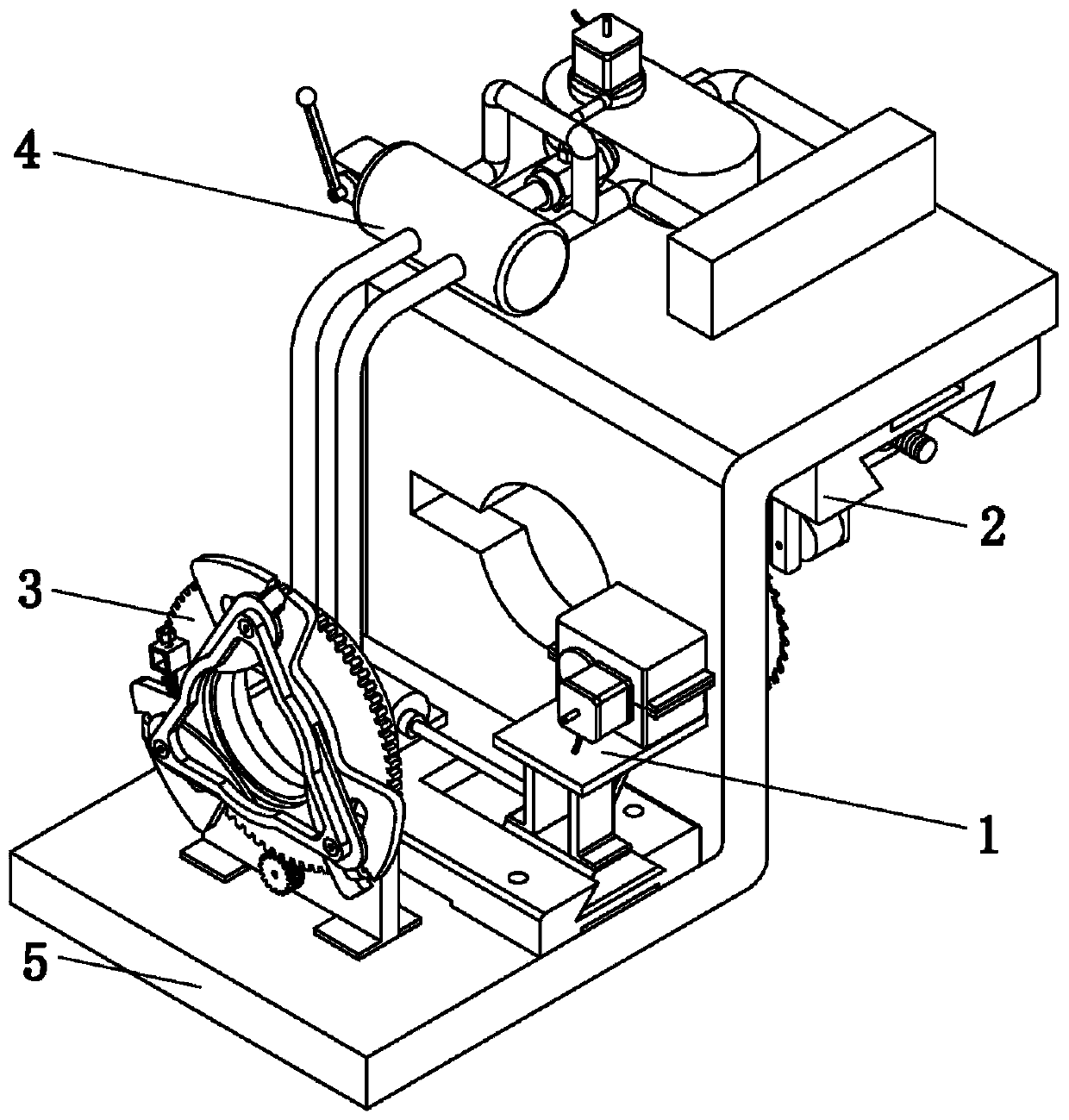

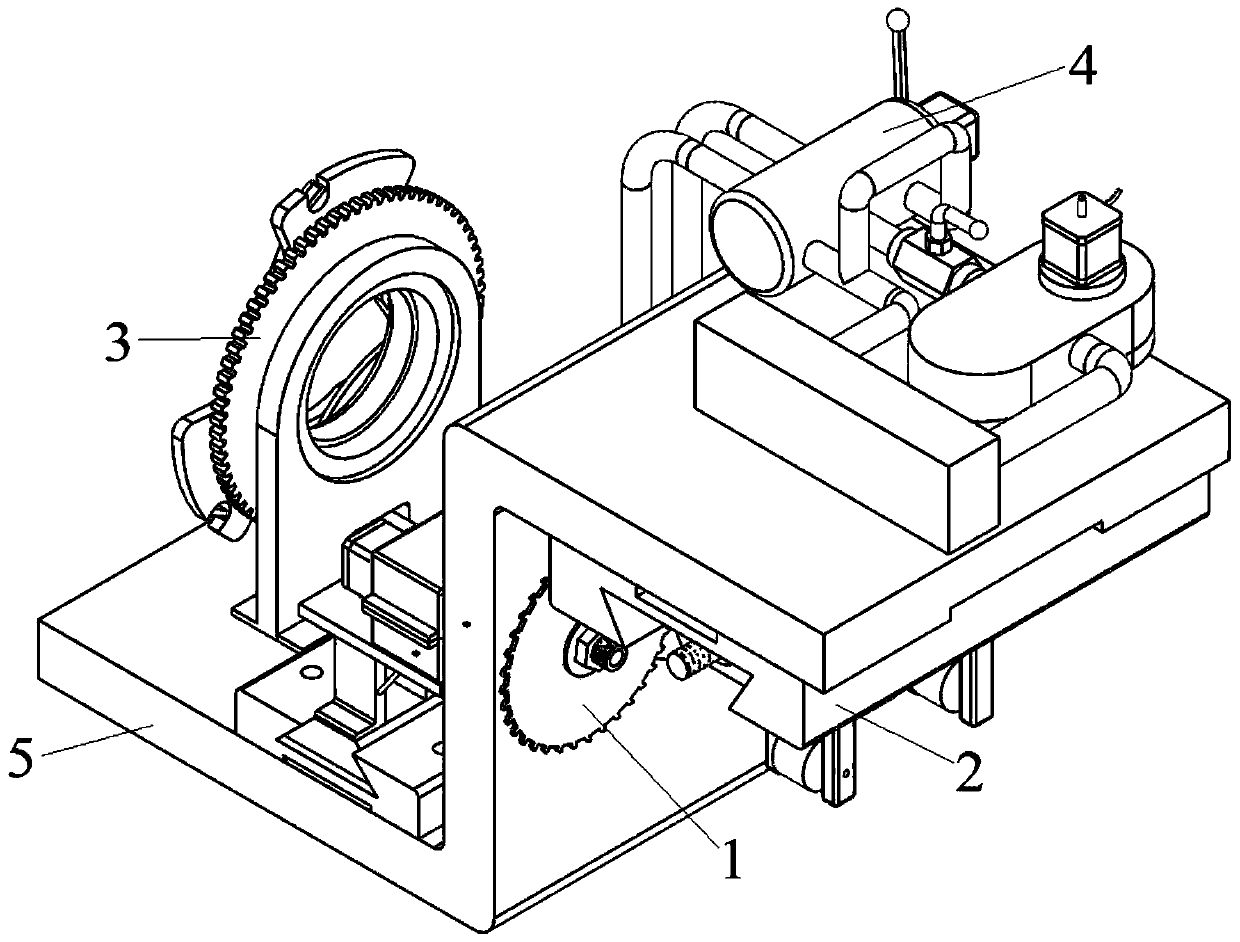

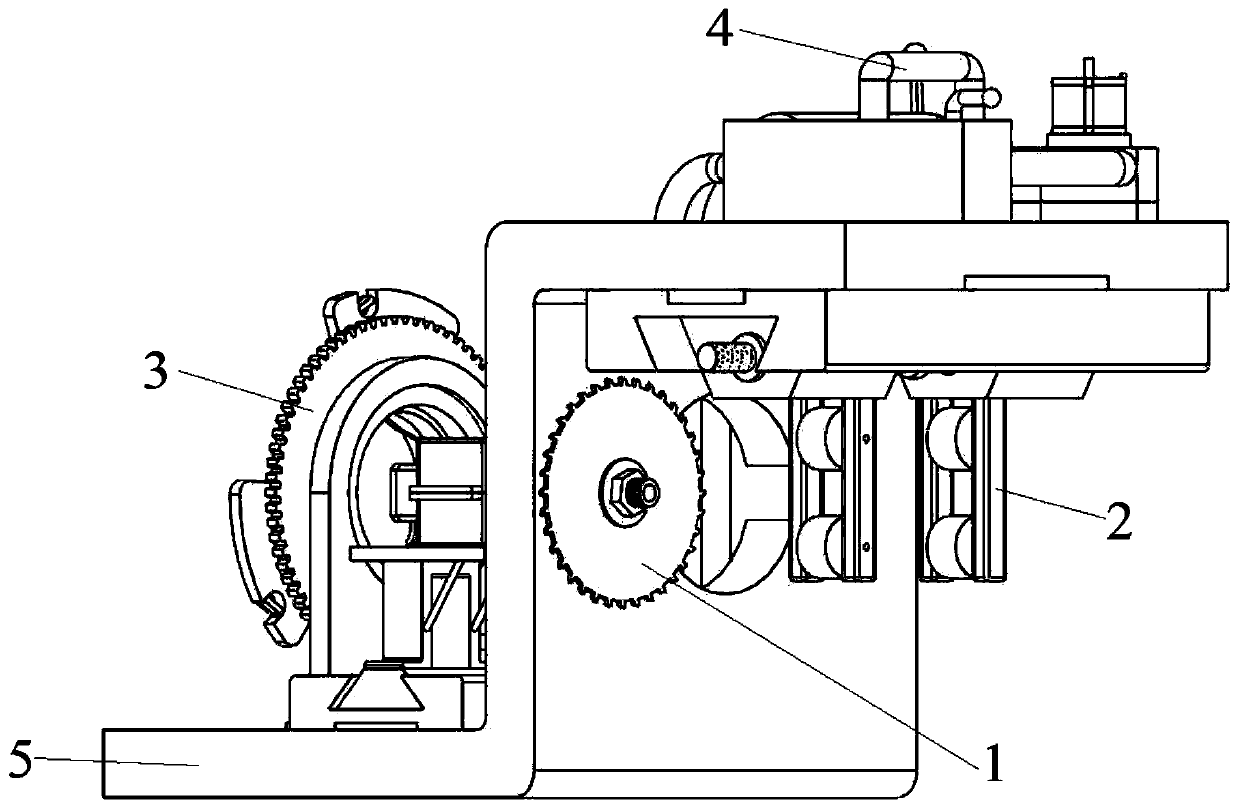

[0032] The invention provides a metal pipe cutting device (referred to as cutting device, see Figure 1-10 ), characterized in that the cutting device includes a cutting mechanism 1, a first clamping mechanism 2, a second clamping mechanism 3, a feed mechanism 4 and a frame 5; the first clamping mechanism 2 and the second clamping mechanism 3 are both It is a self-centering clamping mechanism; the frame 5 is Z-shaped, including an upper wing plate 51, a lower wing plate 52 and a side plate 53; the upper wing plate 51 and the lower wing plate 52 are fixed on two sides of the side plate 53 Side; have positioning hole 531 on the side plate 53, be used for the passage of metal pipe; Have the notch 532 that communicates with locating hole 531 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com