Calculation method of regulating space of slurry circulating system and device thereof

A circulation system and slurry circulation technology, applied in the field of slurry circulation system adjustment space calculation method and its devices, can solve the problems of increased system energy consumption, high energy consumption, and affecting the life of pump motors, etc., to improve safety and stability, and improve desulfurization Efficiency, the effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

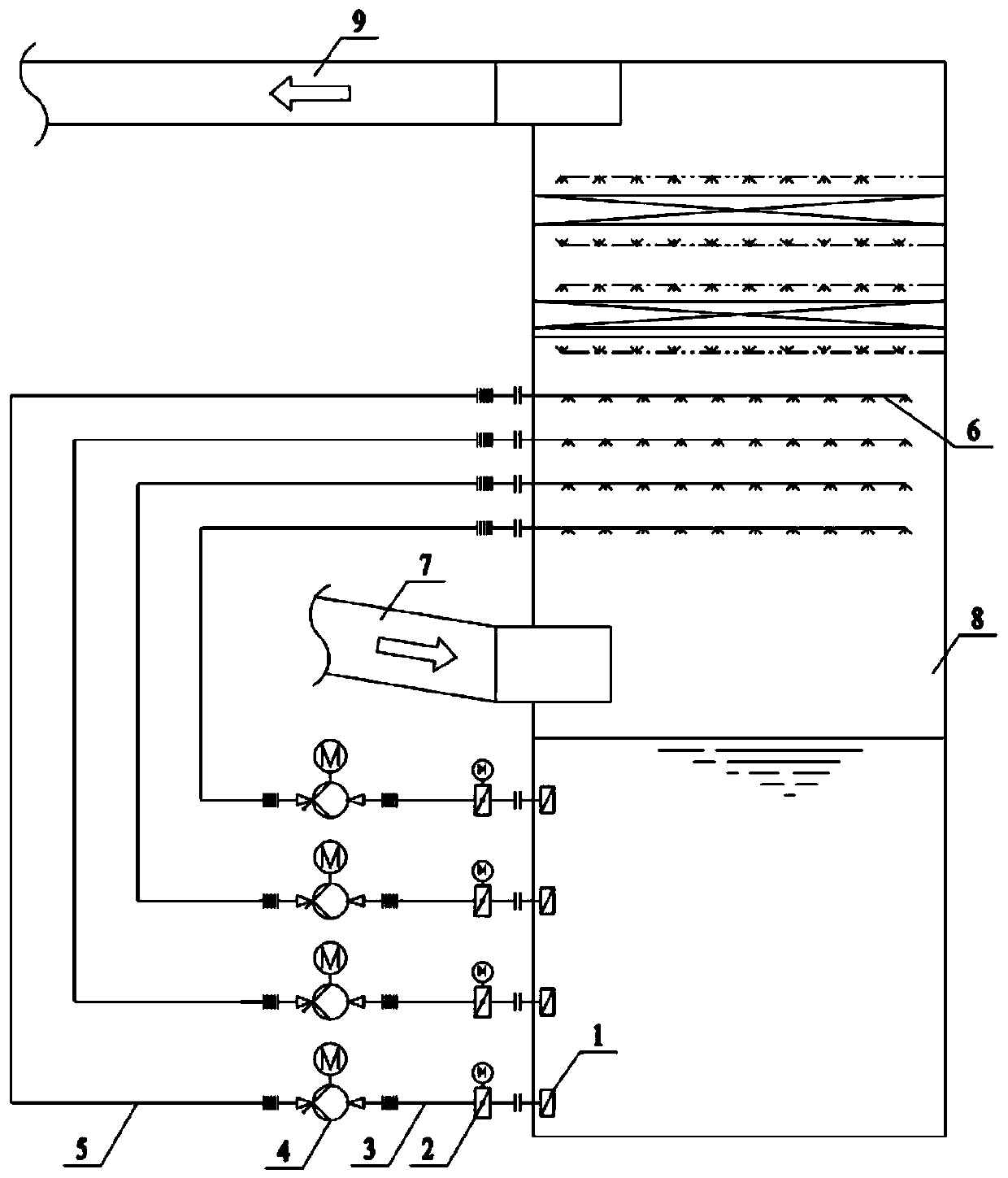

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings.

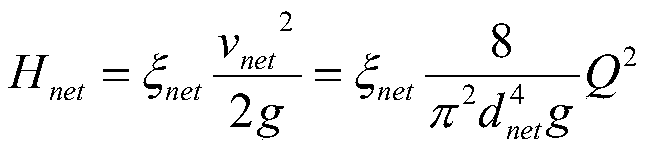

[0051] When the speed of the pump changes, the performance parameters after the speed change can be obtained according to the similarity law:

[0052]

[0053]

[0054]

[0055] In the formula, Q, Q m Respectively, the flow rate before and after the pump speed change, H, H m Respectively, the head of the pump before and after the speed change, P, P m Respectively, the power before and after the pump shift, n, n m Respectively, the speed of the pump before and after the speed change.

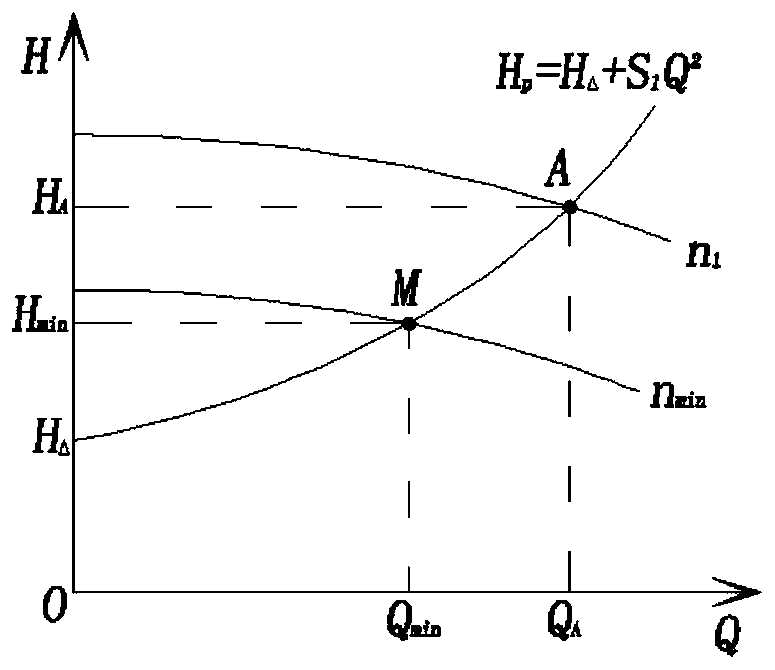

[0056] However, the law of similarity is only applicable to similar working condition points, and the characteristic curve of the slurry circulation pipeline does not pass through the origin, and does not coincide with the proportional curve of any over-operating condition point, so the operating condition points at different speeds are not similar during adjustment , the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com