A disassembly tool for hydraulic oil tank in manual opening mechanism of aircraft canopy

A hydraulic fuel tank and aircraft cockpit technology, applied in the field of aviation equipment, can solve problems such as affecting aircraft attendance, difficulty in repair work, personal casualties, etc., and achieve the effects of reliable use, convenient disassembly and assembly, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

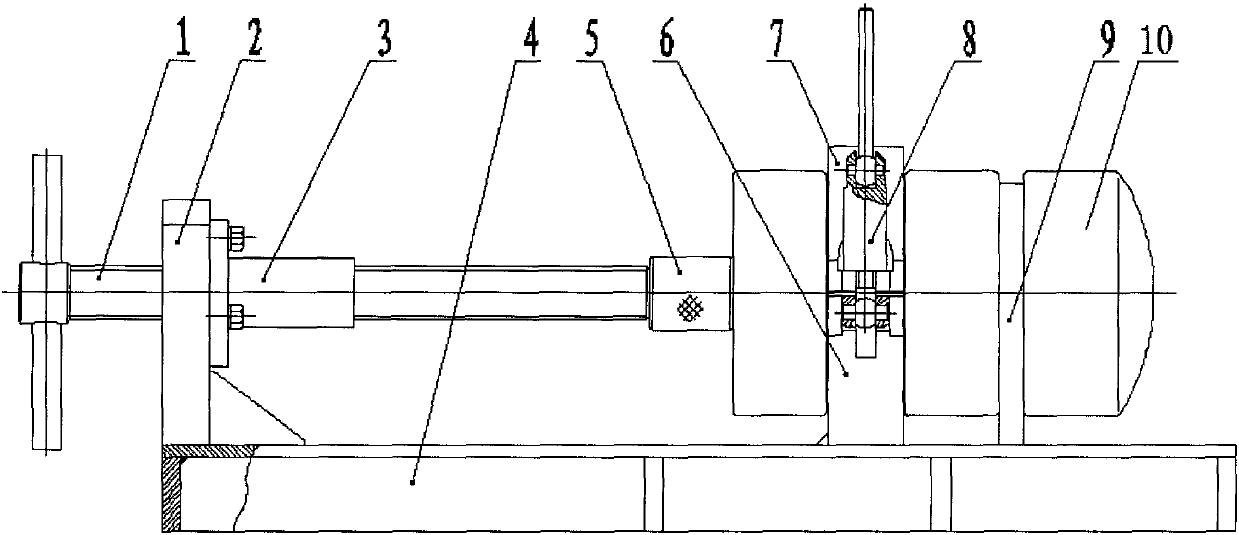

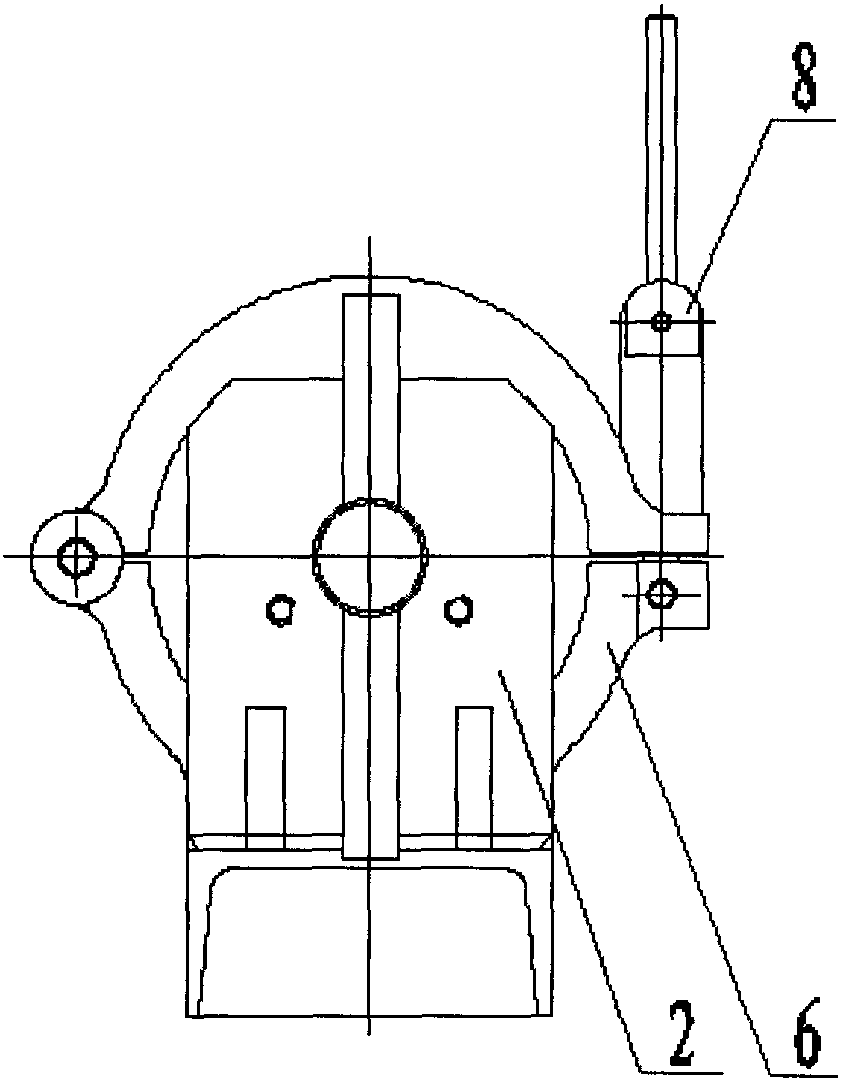

[0020] Such as figure 1 with figure 2 As shown, a disassembly tool for a hydraulic oil tank 10 in a manual opening mechanism of an aircraft canopy, the tool includes: a screw 1, a screw seat 2, a guide sleeve 3, a base 4, a hexagonal wrench head 5, a lower snap ring 6, an upper Snap ring 7, locking mechanism 8 and support seat 9, peripheral equipment includes hydraulic oil tank 10;

[0021] Wherein, the lower snap ring 6, the upper snap ring 7, and the support seat 9 are all semicircular structures;

[0022] The hydraulic oil tank 10 is a cylindrical structure, including a case cover and a case body, and the case cover and the case body are threadedly connected, and the outer center of the case cover of the hydraulic oil tank 10 has a hexagonal head;

[0023] The connection relationship is as follows:

[0024] The screw seat 2, the lower snap ring 6, and the support seat 9 are fixed on the base 4 sequentially from left to right, and the guide sleeve 3 is fixed on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com