Vertical type double-color injection molding machine

A two-color injection molding machine, vertical technology, applied in the field of vertical two-color injection molding machine, can solve the problems of low precision, lower product pass rate, increase production cost, etc., and achieve the effect of not easy to offset, high production efficiency, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with accompanying drawing:

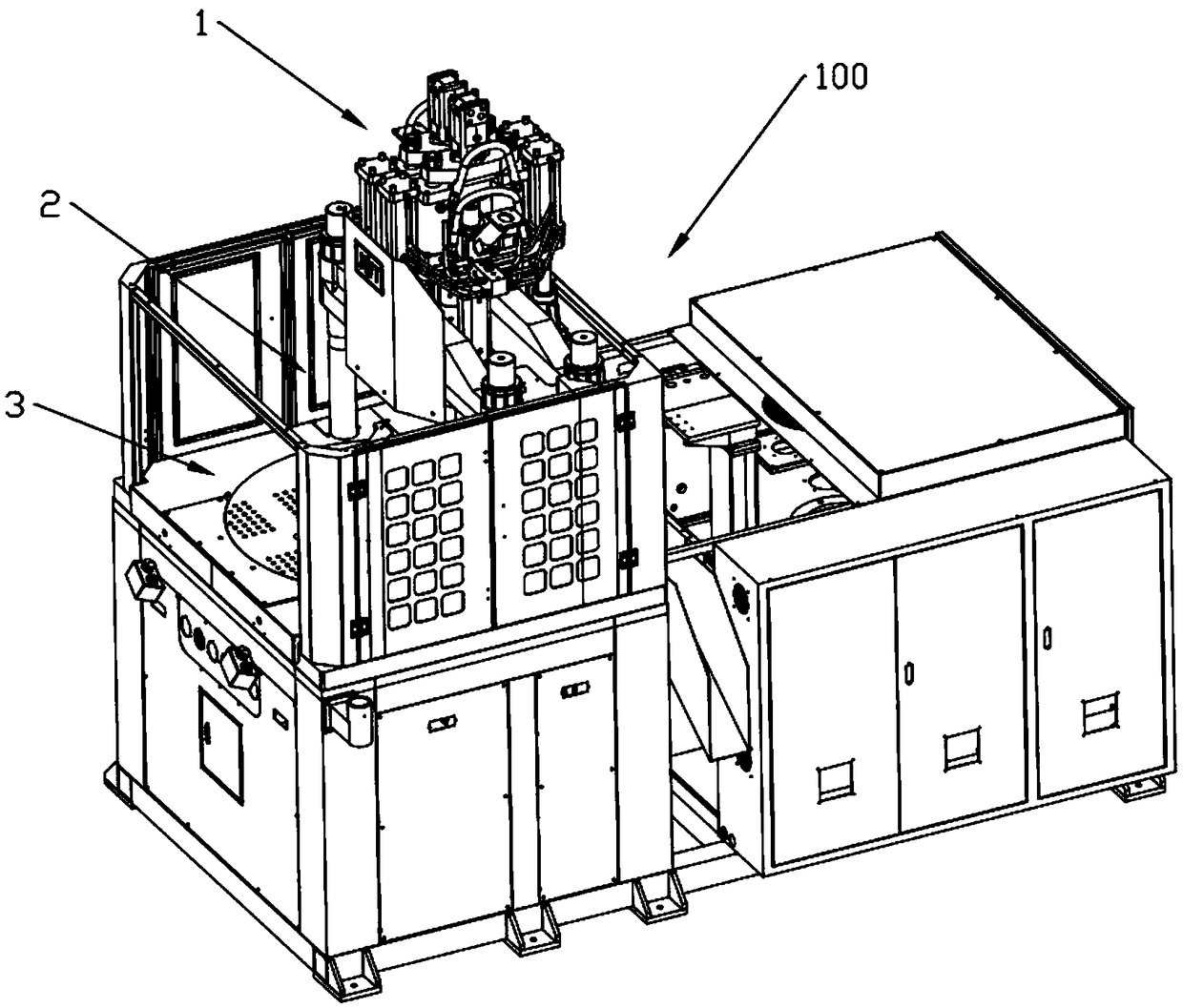

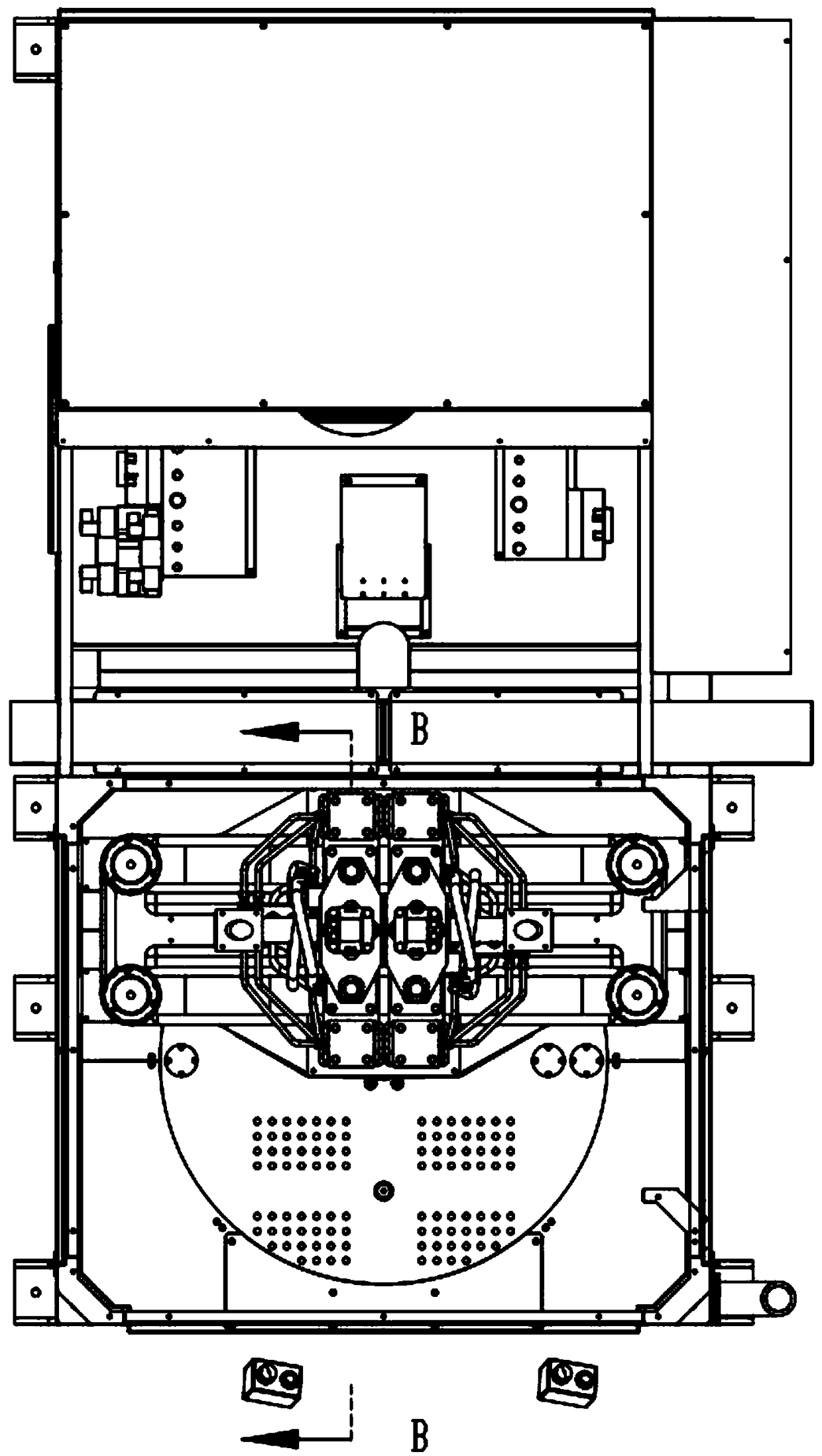

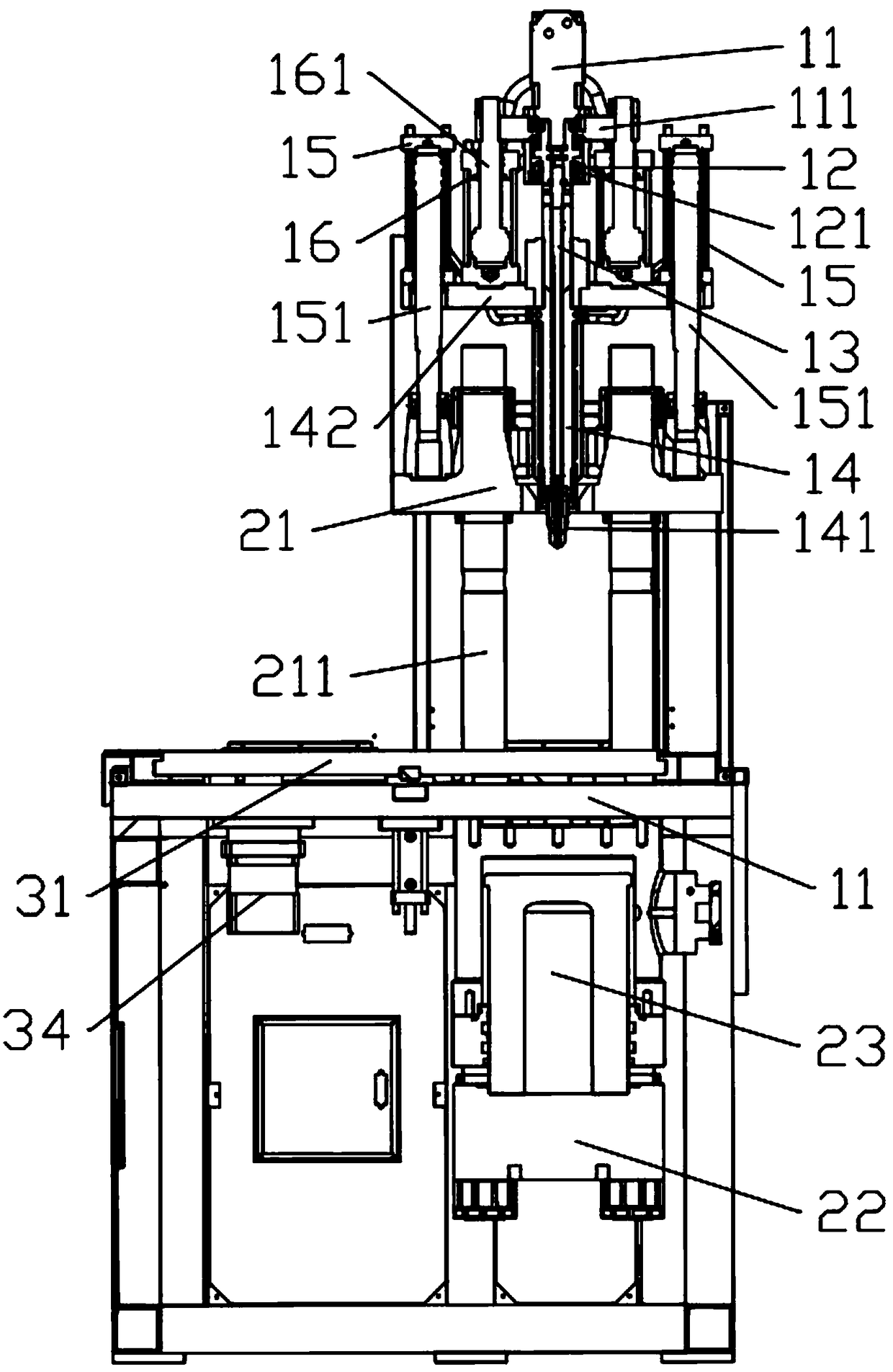

[0023] A vertical two-color injection molding machine, including a frame 100, the frame 100 includes at least two injection molding devices 1, a mold clamping device 2 matched with the injection molding device 1, and a turntable device 3, and the mold clamping device 2 includes an upper template 21 and for The guide column 211 supporting the upper template 21, the frame 100 includes an operation table 11, the operation table 11 can be inserted on the guide column 211, the turntable device 3 is rotatably arranged on the operation table 11, and the mold clamping device 2 is located on the operation table 11 at the lower end, the mold is located between the turntable device 3 and the upper template 21, the mold clamping device 2 controls the console 11 to rise to close the mold, the injection molding device 1 squeezes the plastic into the mold, and the mold clamping device 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com