Method for manufacturing an electronic or electrical system, and system which is manufactured in accordance with the method

An electrical system and electronic technology, which is applied in the direction of printed circuits, manufacturing tools, additive manufacturing, etc. connected to non-printed electrical components, can solve problems such as inaccuracy, high power density heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

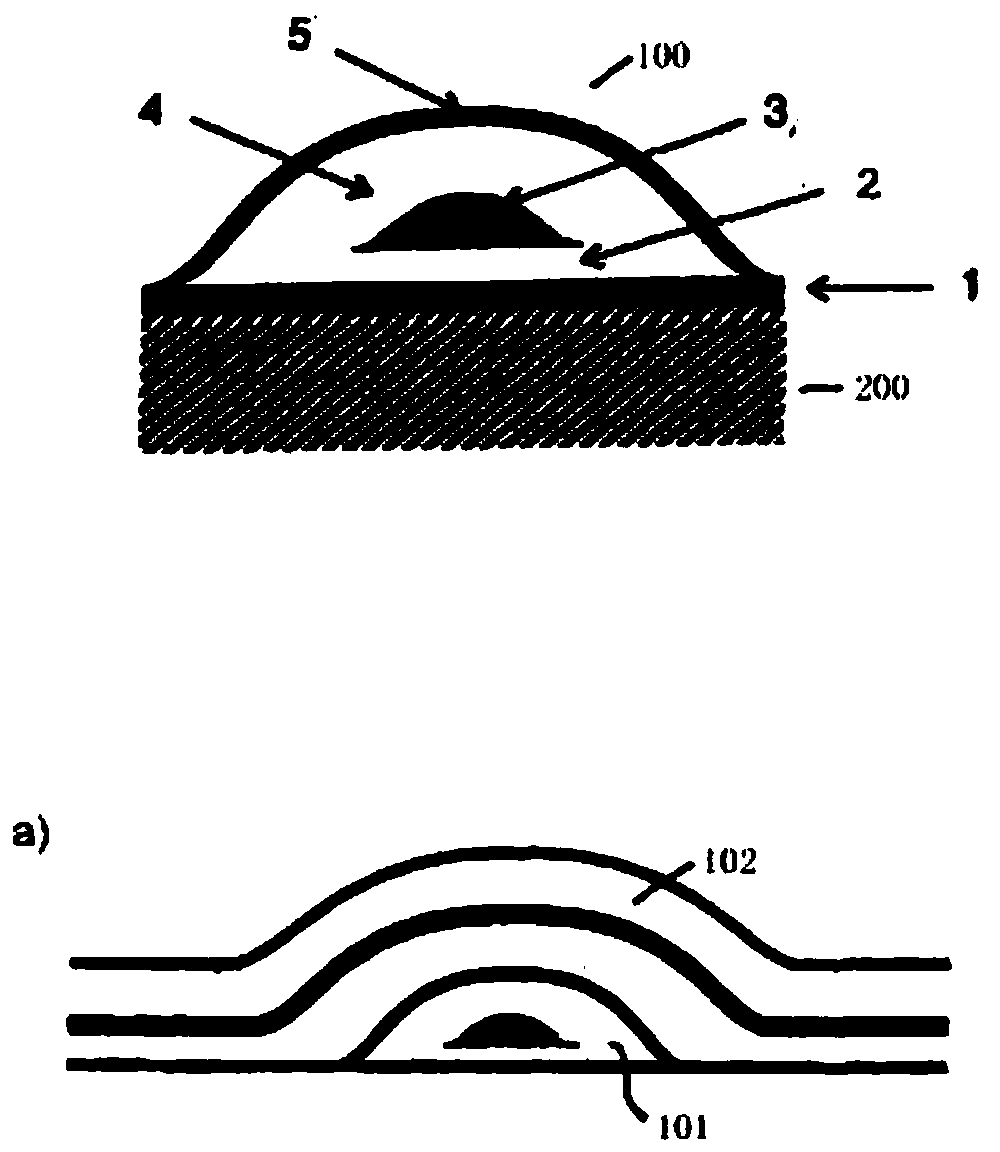

[0100] figure 1 A conductive layer is shown with reference numeral 1, which corresponds to the width of the signal line 100 and forms the bottom surface thereof. A dielectric layer 2 is applied on top of this layer, on which, depending on the type of conductor, no conductor tracks, one or more conductor tracks 3 are produced. exist figure 1 Over the entire width of the signal lines shown on the carrier 200 indicated by hatching, a further dielectric encapsulation 4 follows, which together with the layer 2 completely encloses one or more rails. The structure produced in this way is provided with an encapsulation 5 which consists entirely of metal or is metallized at least on its inside or outside and which forms an electrically conductive connection with layer 1 . This results in a completely circumferential, that is to say in the cross-sectional direction, electrically conductive housing. The housing can consist of metal or be metallized or consist of or be coated with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com