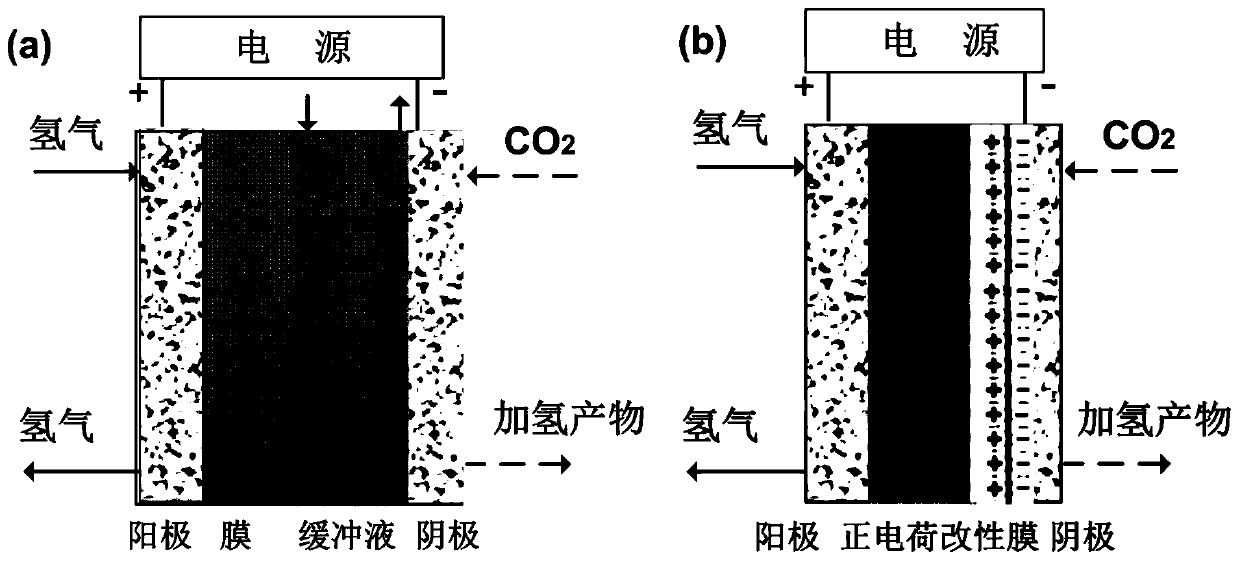

Method for controlling cathode potential in electrochemical hydrogen pump CO2 hydrogenation reactor by film method

A technology of hydrogenation reactor and cathode potential, which is applied in the field of electrochemical engineering, can solve the problems of increasing hydrogen proton mass transfer resistance, submerging gas transfer channels, and serious side reactions of hydrogen evolution, so as to improve hydrogenation reaction rate and conversion rate, The effect of reducing device resistance and promoting hydrogenation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

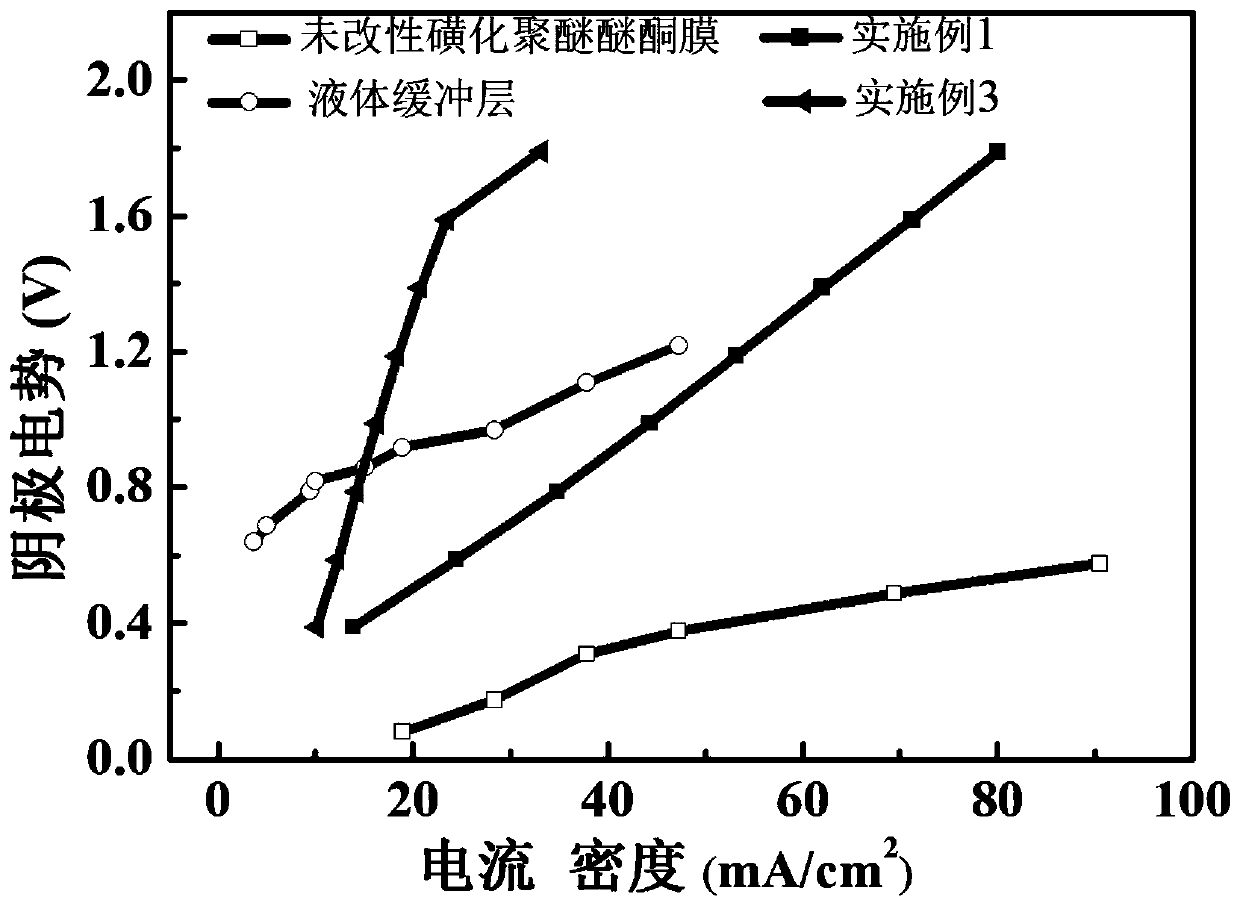

Embodiment 1

[0021] Soak the sulfonated polyether ether ketone base membrane with a sulfonation degree of 57% in MgCl with a concentration of 3mol / L 2 As an aqueous solution, heat and stir in a water bath at 80°C for 12 hours, wash with deionized water, dry, and press the membrane electrode. Specifically: after the modified proton exchange membrane is dried in an oven at 80°C, it is sandwiched between two carbon paper diffusion layers coated with cathode and anode catalysts on one side, and hot-pressed at 150°C and 3.5MPa for 100s. Membrane electrode, and then assemble the membrane electrode between two graphite plates engraved with serpentine flow channels.

[0022] The constant voltage operation was performed in an electrochemical hydrogen pump reactor, and the reaction was performed for 2 h at each voltage within the voltage range of 0.4-1.2 V (relative to the standard hydrogen electrode). When the operating voltage is 1.2V (relative to the standard hydrogen electrode), the current den...

Embodiment 2

[0024] Preparation of sulfonated polyether ether ketone membrane modified by ion exchange method and research on hydrogenation performance: soak the sulfonated polyetheretherketone base membrane with a sulfonation degree of 45% in an aqueous KCl solution with a concentration of 2 mol / L in a water bath at 85 °C Heat and stir for 4h, wash with deionized water, dry, and press the membrane electrode. Specifically: After drying the modified proton exchange membrane in an oven at 70°C, sandwich it between two carbon paper diffusion layers coated with cathode and anode catalysts on one side, and press it at 160°C and 3MPa for 110s to make a membrane electrode. , and then assemble the membrane electrode between two graphite plates engraved with serpentine flow channels.

[0025] The constant voltage operation was performed in an electrochemical hydrogen pump reactor, and the reaction was performed for 2 h at each voltage within the voltage range of 0.4-1.2 V (relative to the standard ...

Embodiment 3

[0027] Preparation of layer-by-layer self-assembled modified sulfonated polyether ether ketone membrane and research on hydrogenation performance: the sulfonated polyether ether ketone material with a sulfonation degree of 71% was heated and dissolved in deionized water to prepare a negatively charged polymer solution ; The polyquaternary ammonium salt material is dissolved in deionized water to prepare a positively charged polymer solution, and the mass concentration of the two solutions is 86.1%. Soak the sulfonated polyether ether ketone membrane with a sulfonation degree of 67% in the positively charged polymer solution for 30 minutes, take it out and wash it with deionized water, then immerse it in the negatively charged polymer solution for 30 minutes, take it out and deionized water cleaning. The above steps are carried out alternately, and three layers of positively charged polyquaternary ammonium salts are introduced on the surface of the sulfonated polyether ether ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com