Nitrification microbial fuel cell

A technology of fuel cells and microorganisms, which is applied in the fields of biochemical fuel cells, fuel cells, and components of fuel cells, etc., can solve the problems of low energy utilization rate, harsh operating conditions, and complex battery structure, and achieves simple structure and mild operating conditions. , the effect of good battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

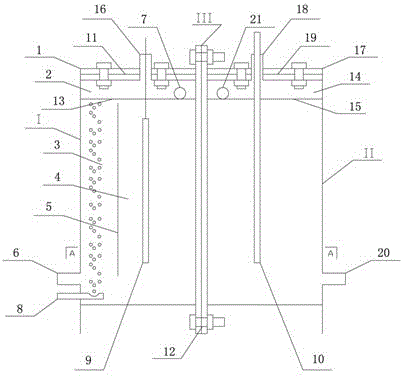

[0015] Such as figure 1 , 2 As shown, the nitrifying microbial fuel cell is composed of an anode chamber I, a cathode chamber II and a proton exchange membrane III; the anode chamber I and the cathode chamber II are provided with a proton exchange membrane III and connected by a flange 12; the anode chamber I is provided with an anode chamber The cubic reactor 2 and the sealing cover 1 are connected by a flange 11 between the anode chamber cubic reactor 2 and the sealing cover 1; the lower part of the cubic reactor 2 is provided with a water inlet pipe 6, and the upper part of the cubic reactor is provided with an outlet pipe 7. The middle part of the cubic reactor is provided with an aeration zone 3, a reaction zone 4 and an isolation plate 5. The aeration zone 3 and the reaction zone 4 are separated by the isolation plate 5, connected up and down and filled with an electricity-generating matrix 13; an electricity-generating matrix 13 Place the nitrifying bacteria hanging fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com