Intelligent automatic detection method for clutch driven disc

An automatic detection and clutch technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve problems such as customer dissatisfaction, unstable product quality, and uncontrolled quality, so as to reduce production costs and improve production Efficiency and product quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

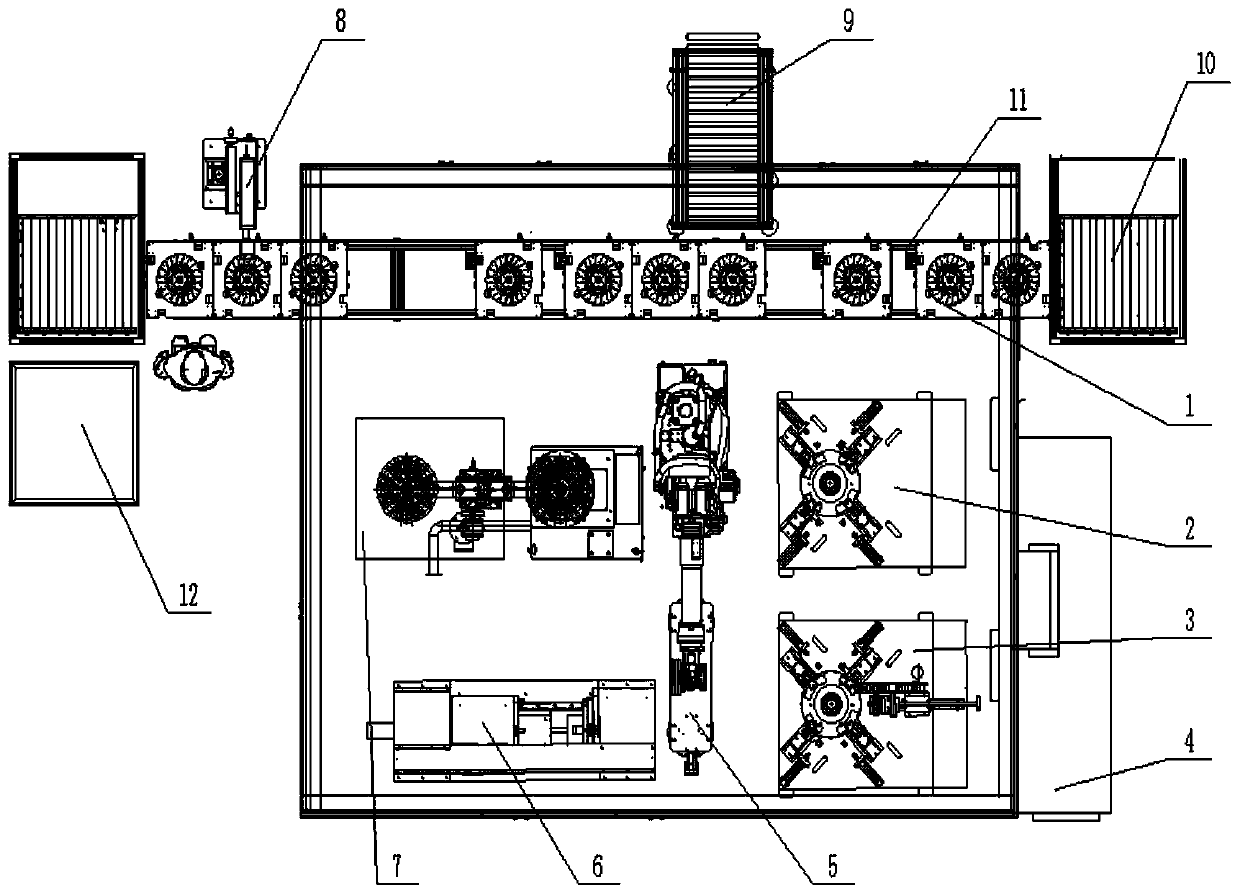

[0008] 1. See figure 1 , an intelligent automatic detection method for a clutch driven disc according to this specific embodiment, its composition includes: a feeding tray 1, a running-in machine 2, a torsional stiffness detection machine 3, an electric control cabinet 4, a robot 5, a drag detection machine 6, Balance detection and correction machine 7, marking machine 8, unqualified feeding roller table 9, elevator 10, assembly line 11 and qualified product feeding transfer box 12, including feeding tray 1, grinding machine 2, torsional rigidity testing machine 3, Electric control cabinet 4, robot 5, dragging inspection machine 6, balance inspection and correction machine 7, marking machine 8, unqualified feeding roller table 9, elevator 10, assembly line 11 and qualified product feeding transfer box 12 all pass through the ground Expansion bolt connection, driven disc running-in machine 2 automatically takes the assembly and places it on the equipment, automatic running-in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com