Metering device suitable for high water cut experiment and metering method

The technology of a metering device and a metering method, which is applied in the field of petroleum engineering, can solve the problems of small oil production and influence on accuracy, and achieve the effects of real-time metering, low cost and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

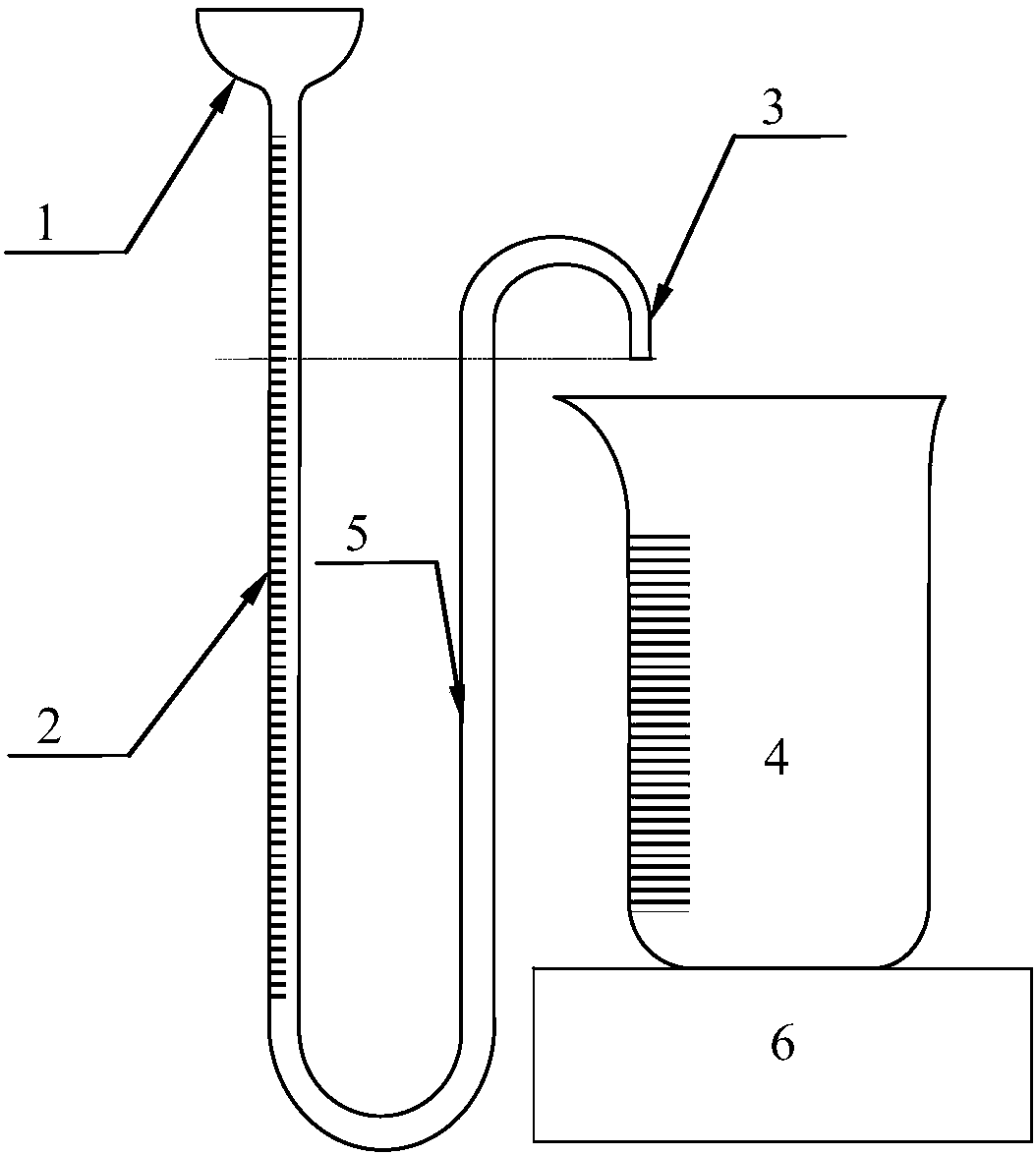

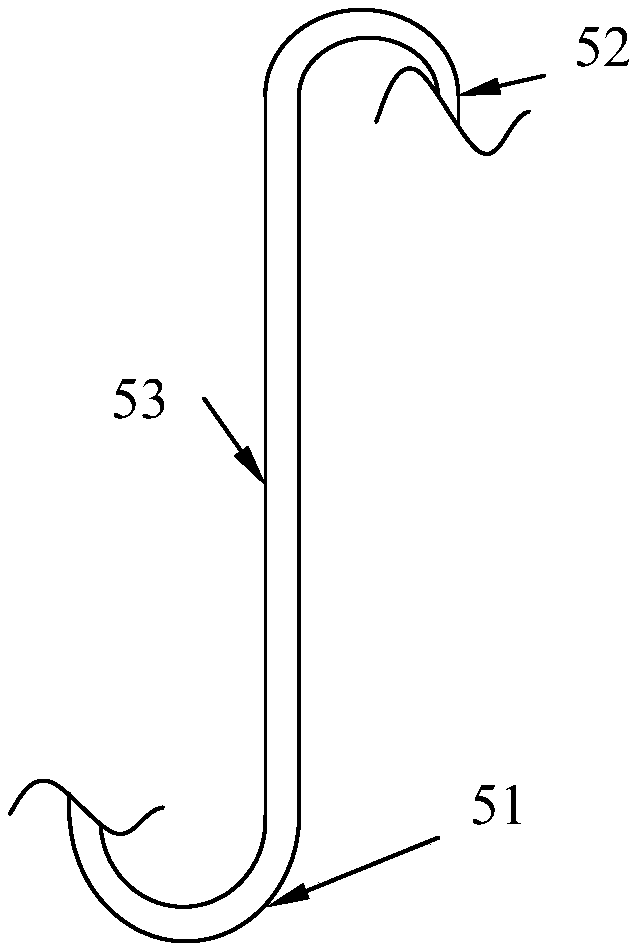

[0073] figure 1 A schematic structural diagram of a metering device suitable for high water content experiments is shown according to an exemplary embodiment of the present invention. figure 2 A schematic diagram of a connecting pipe according to an exemplary embodiment of the present invention is shown.

[0074] Such as figure 1 and figure 2 As shown, a metering device suitable for high water cut experiments in this embodiment includes an oil production metering unit and a liquid production metering unit, wherein the oil production metering unit includes:

[0075] Connecting pipe 5, connecting pipe 5 comprises a vertical pipe section 53, a first U-shaped pipe section 51 and a second U-shaped pipe section 52, and the two ends of the vertical pipe section 53 are respectively connected with the first U-shaped pipe section 51 and the second U-shaped pipe section 52 , the other end of the second U-shaped pipe section 52 is the liquid outlet 3;

[0076] Metering tube 2, the m...

Embodiment 2

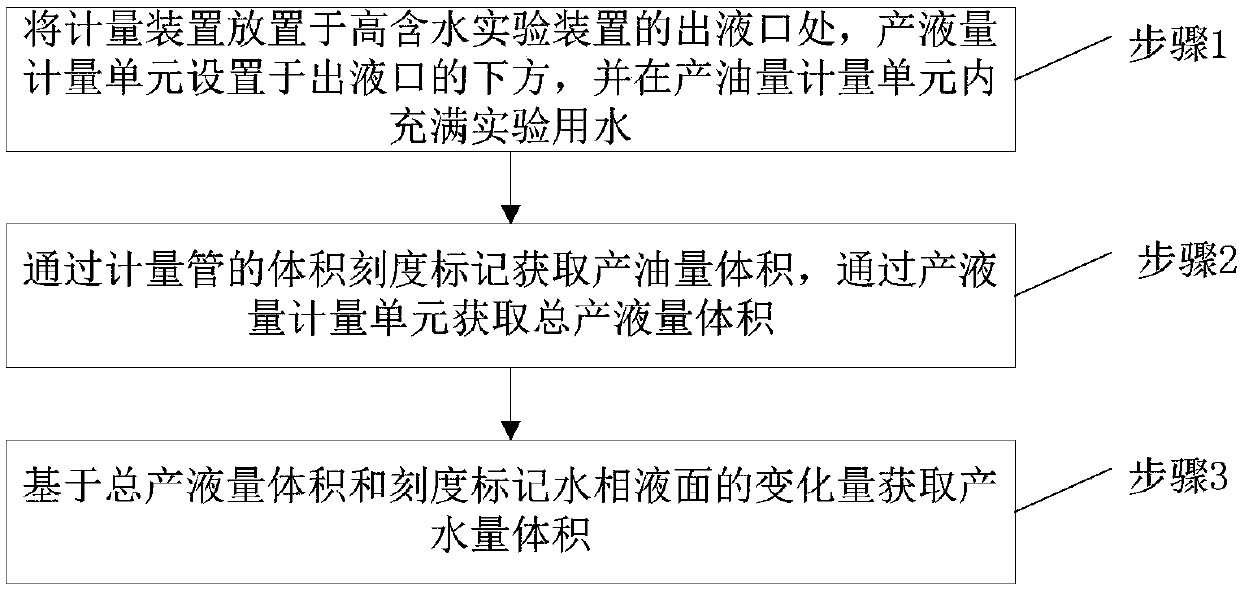

[0088] image 3 A schematic flow chart showing a metering method suitable for high water content experiments according to an exemplary embodiment of the present invention is shown.

[0089] Such as image 3 As shown, a kind of metering method suitable for high water content experiment of the present embodiment comprises:

[0090] Step 1, placing the metering device at the liquid outlet 3 of the high water content experimental device, setting the liquid production measurement unit below the liquid outlet 3, and filling the oil production measurement unit with experimental water;

[0091] Step 2, the volume of oil production is obtained through the volume scale mark of metering tube 2, and the volume of total liquid production is obtained through the liquid production measurement unit;

[0092] Step 3, obtain the water production volume based on the total liquid production volume and the change in the water phase liquid level of the scale mark;

[0093] Utilize the metering d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com