Gas eddy preventing combustion device

A combustion device and gas vortex technology, which are applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as flame instability, and achieve the effects of stable and uniform production, convenient processing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

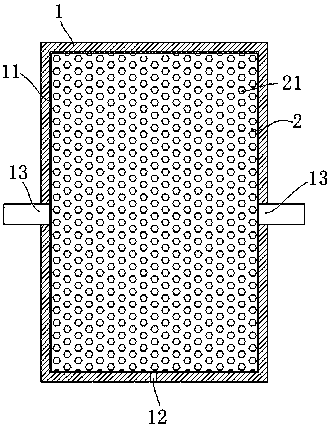

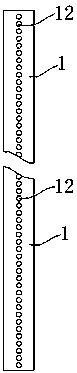

[0024] Embodiment 1 of the anti-gas vortex combustion device: the anti-gas vortex combustion device of this embodiment is mainly used for heating during the process of melting quartz raw materials to draw quartz fibers, including a combustion device housing 1, the combustion device housing of this embodiment 1. It is rectangular and strip-shaped, and 100 combustion holes are distributed on the periphery of the rectangular shell. The combustion device casing 1 is provided with an air intake hole 13, and the air intake hole 13 is connected with a combustion gas pipeline. Combustion gas cavity 11 is formed inside the combustion device housing 1 to accommodate the airflow. The combustion gas cavity 11 is filled with a honeycomb-shaped pressure equalizer 2. The pressure equalizer 2 is processed by 3D printing. The inside of the pressure equalizer 2 A plurality of curved airflow passages 21 are formed for the passage of airflow, and the pressure of the airflow is reduced during the ...

Embodiment 2

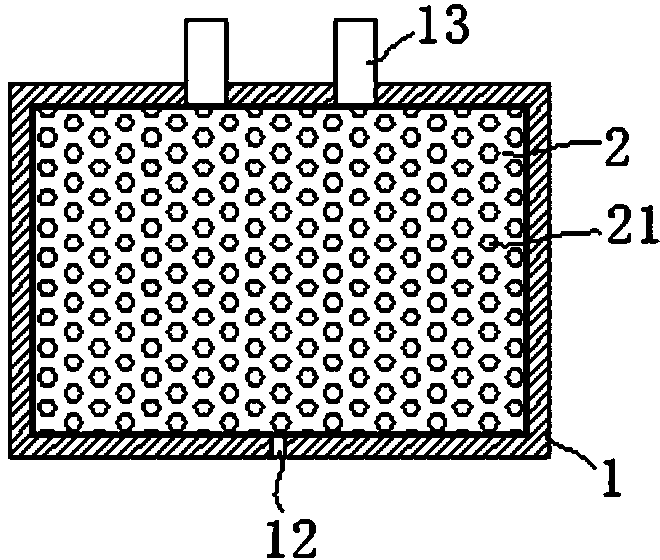

[0026] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 is that the air intake hole and the combustion hole are respectively arranged on the opposite side walls of the combustion device housing.

[0027] In other embodiments: the shape of the combustion device housing can also be replaced by a cylinder, T-shaped or other prismatic or special-shaped; the number of combustion holes is not limited to 100, and can also be set to be less than 100 or greater than 100, the number of combustion holes The arrangement can be linear or non-linear; the number of air intake holes can also be replaced by one or at least three; The hole can be set at any position and can be lowered by the pressure equalizing piece, so that the airflow blown out from the combustion hole is very stable; the pressure equalizing piece can also be processed by other methods, such as casting; the pressure equalizing piece can not only be a one-piece structure , can also be replaced by a split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com