Composite connecting pipe

A composite connection and flexible connection technology, applied in the field of pipelines, can solve the problems of single function, unsightly appearance and poor versatility of water pipes, and achieve the effect of simplifying the structure, beautiful appearance and preventing direct rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

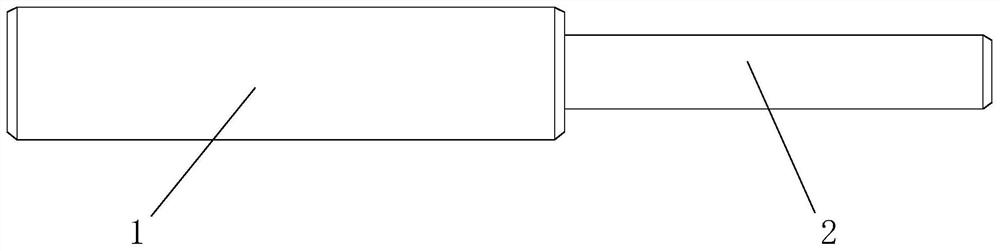

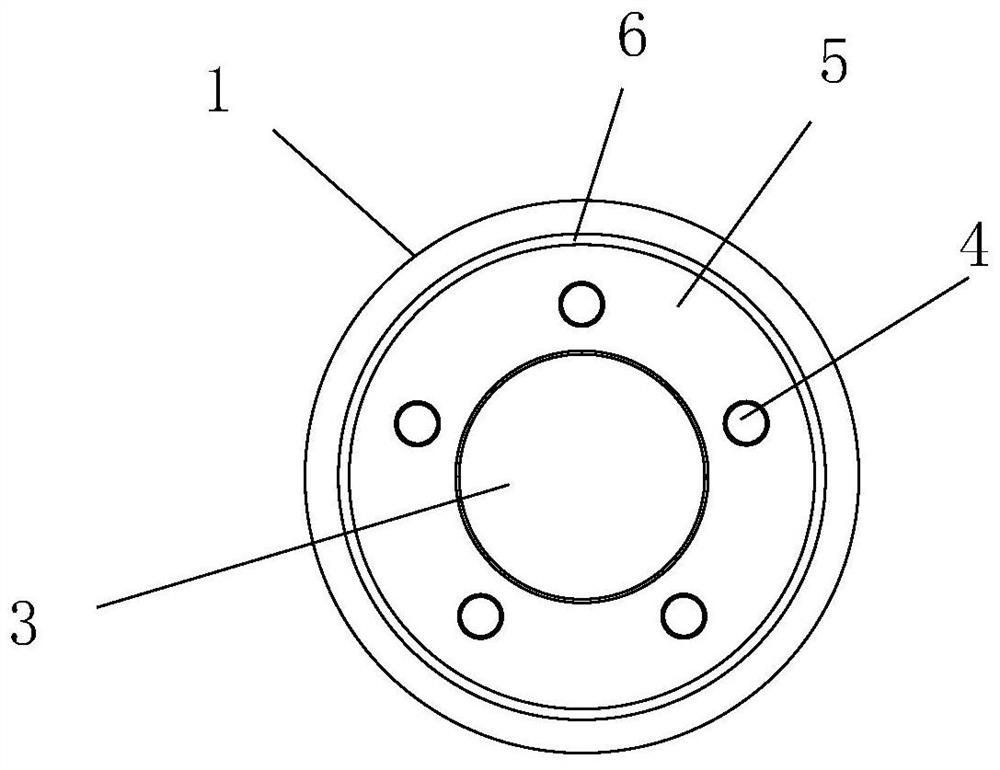

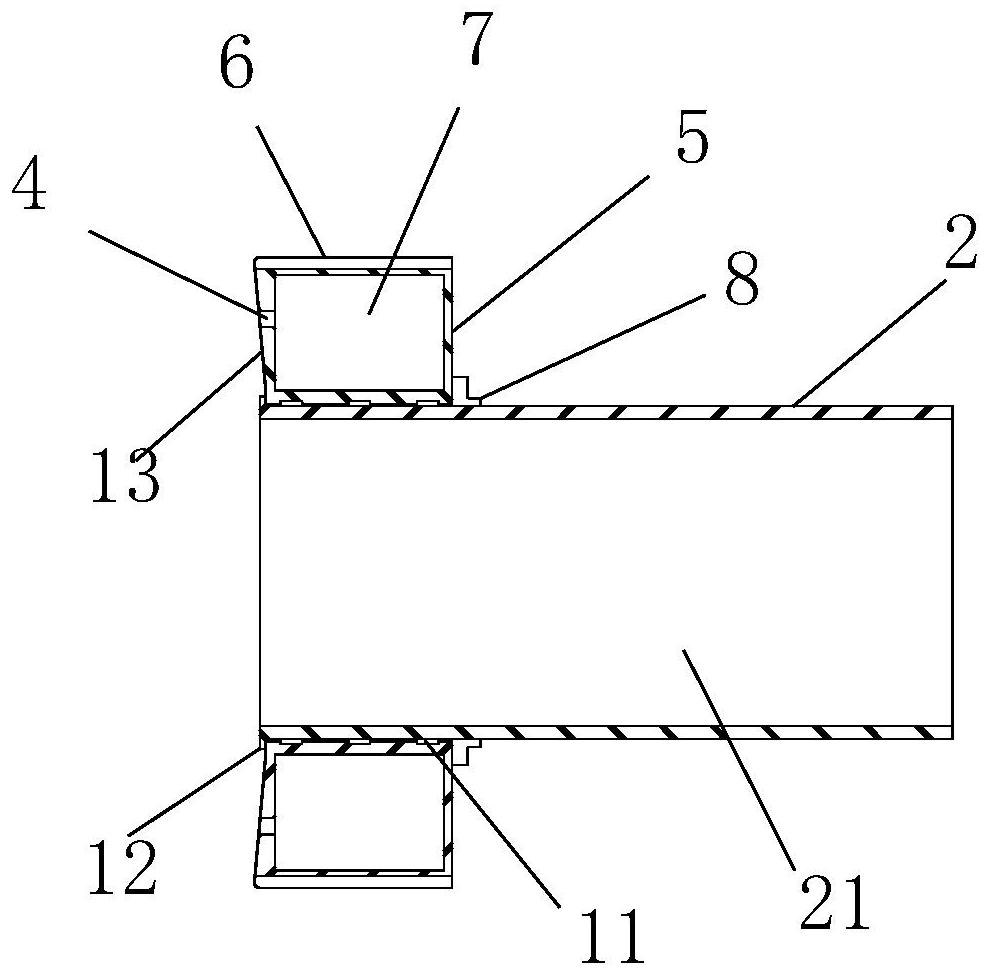

[0019] Such as figure 1 and figure 2 As shown, the composite connecting pipe includes a first pipe 1 and a second pipe 2 with an inner diameter smaller than that of the first pipe 1, and a flexible connecting ring 5 is fixedly installed in the first pipe cavity inside the first pipe 1 near the open end. In the middle of the flexible connecting ring 5 there is an assembly hole 3 with a function of extruding and expanding. The second pipe 2 protrudes into the first pipe cavity and is inserted into the assembly hole 3 for sealing assembly.

[0020] Such as image 3 As shown, the flexible connecting ring 5 is made of an elastic rubber material, and has a cavity 7 inside, the second pipe 2 is inserted into the assembly hole and the air in the cavity 7 is squeezed out from more than one small hole 4 , more than one small hole 4 is arranged facing the flow direction of the water flow inside the first pipeline, and the water in the first pipeline cavity enters into the cavity 7 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com