Method for reducing heat treatment deformation of sheet metal angle parts

A technology for heat treatment of deformation and parts, applied in the field of heat treatment, can solve problems such as excessive manual intervention, achieve the effect of improving surface quality, reducing part scrap rate, and reducing the workload of shape correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method for reducing heat treatment deformation of sheet metal angle material parts of the present invention comprises the following steps:

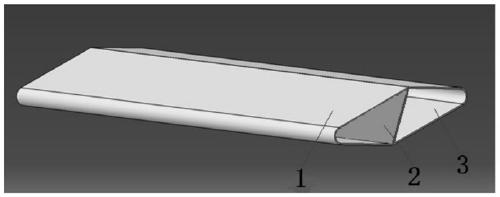

[0016] The first step: process two preforms of the same shape, including the first preform 1 and the second preform 3, the edges opposite to the openings of the two are welding / temporary welding edges, and the size ratio of the welding / temporary welding edges The maximum outer dimension of the part is greater than 5mm; during processing, the square plate is bent according to the actual bending angle of the part, and formed into the first preform 1 and the second preform 3 respectively;

[0017] The second step: processing the reinforcement plate 2, the size of the reinforcement plate is larger than the opening size of the first preform 1 and the second preform 3;

[0018] Step 3: If figure 1 As shown, the preform is symmetrically welded / temporarily welded on both sides of the reinforcement plate to form an intermediate configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com