A kind of malt root protein hydrolyzate with inhibitory alpha-glucosidase activity and preparation method thereof

A protein hydrolyzate and glucosidase technology, applied in the field of malt root protein hydrolyzate and its preparation, to achieve a good effect of inhibiting the activity of α-glucosidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

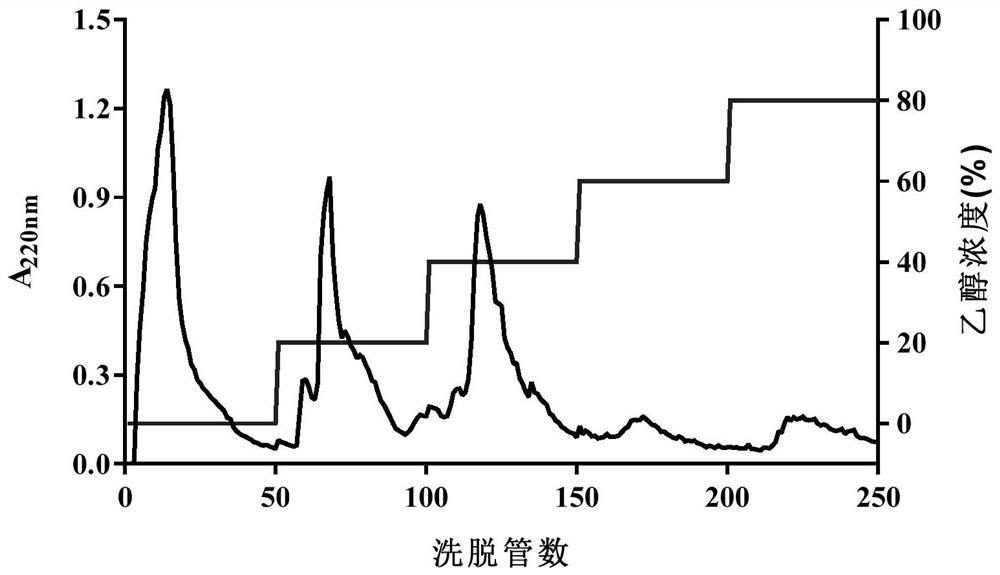

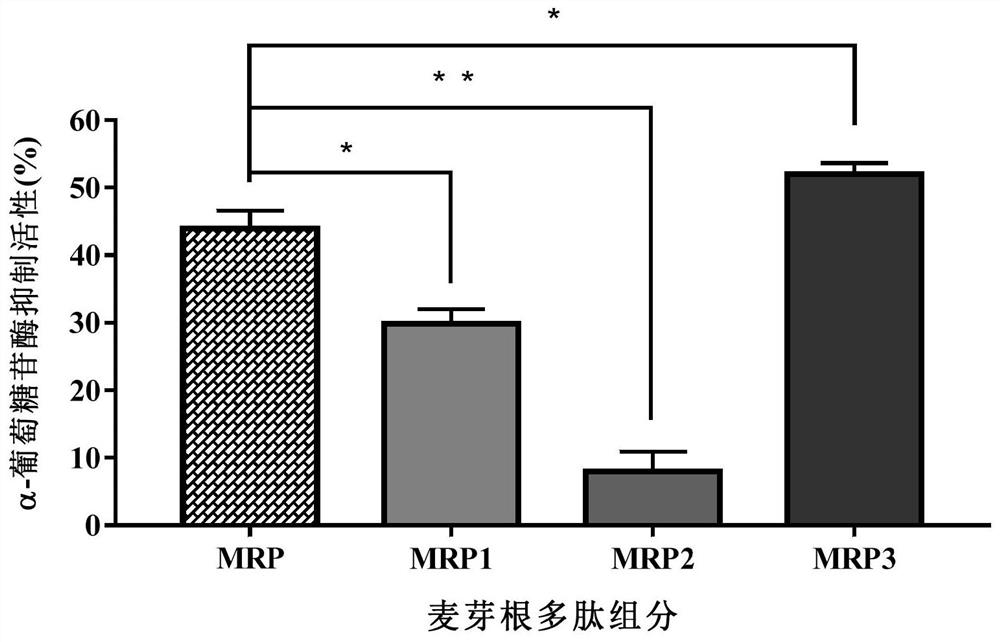

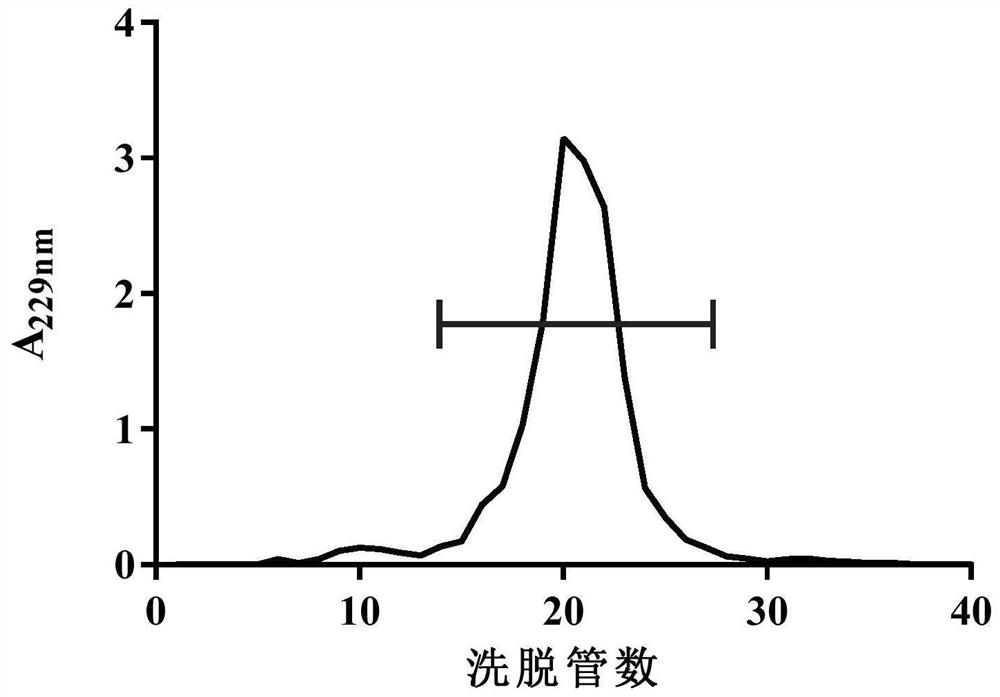

Embodiment 1

[0037] Use a pulverizer to make the malt root into dry powder, pass through a 60-mesh sieve to obtain the malt root dry powder, add deionized water according to a material-to-liquid ratio of 1:10, and mix evenly, wherein the mass of the malt root dry powder is 10g, and the volume of deionized water is 10 g. To 100 mL, Suspension 1 was formed. 0.4% alkaline protease of the mass of the dry powder of malt root was added to the suspension 1, and the enzymatic hydrolysis reaction was carried out at a constant temperature of 50°C, and the enzymatic hydrolysis time was 3 h to obtain the suspension 2. Then heat the suspension 2, the heating temperature is 90°C, and the heating time is 15min. After cooling to room temperature, centrifugation is performed at a low temperature of 4°C. The supernatant was obtained to obtain extract 1. The extract 1 was separated by filtration, the filtrate was taken, and then the pH of the filtrate was adjusted to 7 to obtain the extract 2. AB-8 macropo...

Embodiment 2

[0039] Use a pulverizer to make the malt root into dry powder, pass through an 80-mesh sieve to obtain the malt root dry powder, add deionized water according to a material-to-liquid ratio of 1:15, and mix evenly, wherein the mass of the malt root dry powder is 10g, and the volume of deionized water is 10 g. 150 mL, Suspension 1 was formed. 0.6% alkaline protease by mass of the dry powder of malt root was added to the suspension 1, and the enzymatic hydrolysis reaction was carried out at a constant temperature of 50° C., and the enzymatic hydrolysis time was 4 h to obtain the suspension 2. Then heat the suspension 2, the heating temperature is 95°C, the heating time is 10min, and after cooling to room temperature, centrifugation is carried out at a low temperature of 7°C. The supernatant was obtained to obtain extract 1. The extract 1 was separated by filtration, the filtrate was taken, and then the pH of the filtrate was adjusted to 7.5 to obtain the extract 2. AB-8 macropo...

Embodiment 3

[0041] Use a pulverizer to make the malt root into dry powder, pass through an 80-mesh sieve to obtain the malt root dry powder, add deionized water according to a material-to-liquid ratio of 1:20, and mix well, wherein the mass of the malt root dry powder is 10g, and the volume of deionized water is 10 g. 200 mL, Suspension 1 was formed. 1% alkaline protease by mass of the dry powder of malt root was added to the suspension 1, and the enzymatic hydrolysis reaction was carried out at a constant temperature of 55°C, and the enzymatic hydrolysis time was 4 h to obtain the suspension 2. Then heat the suspension 2, the heating temperature is 100°C, and the heating time is 10min. After cooling to room temperature, centrifugation is performed at a low temperature of 10°C. solution to obtain extract 1. The extract 1 was separated by filtration, the filtrate was taken, and then the pH of the filtrate was adjusted to 7.5 to obtain the extract 2. AB-8 macroporous resin was used to ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com