Glass display screen and preparation process thereof

A display and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass tempering and other directions, can solve the problems of poor imaging effect, complex structure, affecting the viewing effect, etc., to achieve image resolution lossless, smooth surface, The effect of not easy to use eye fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

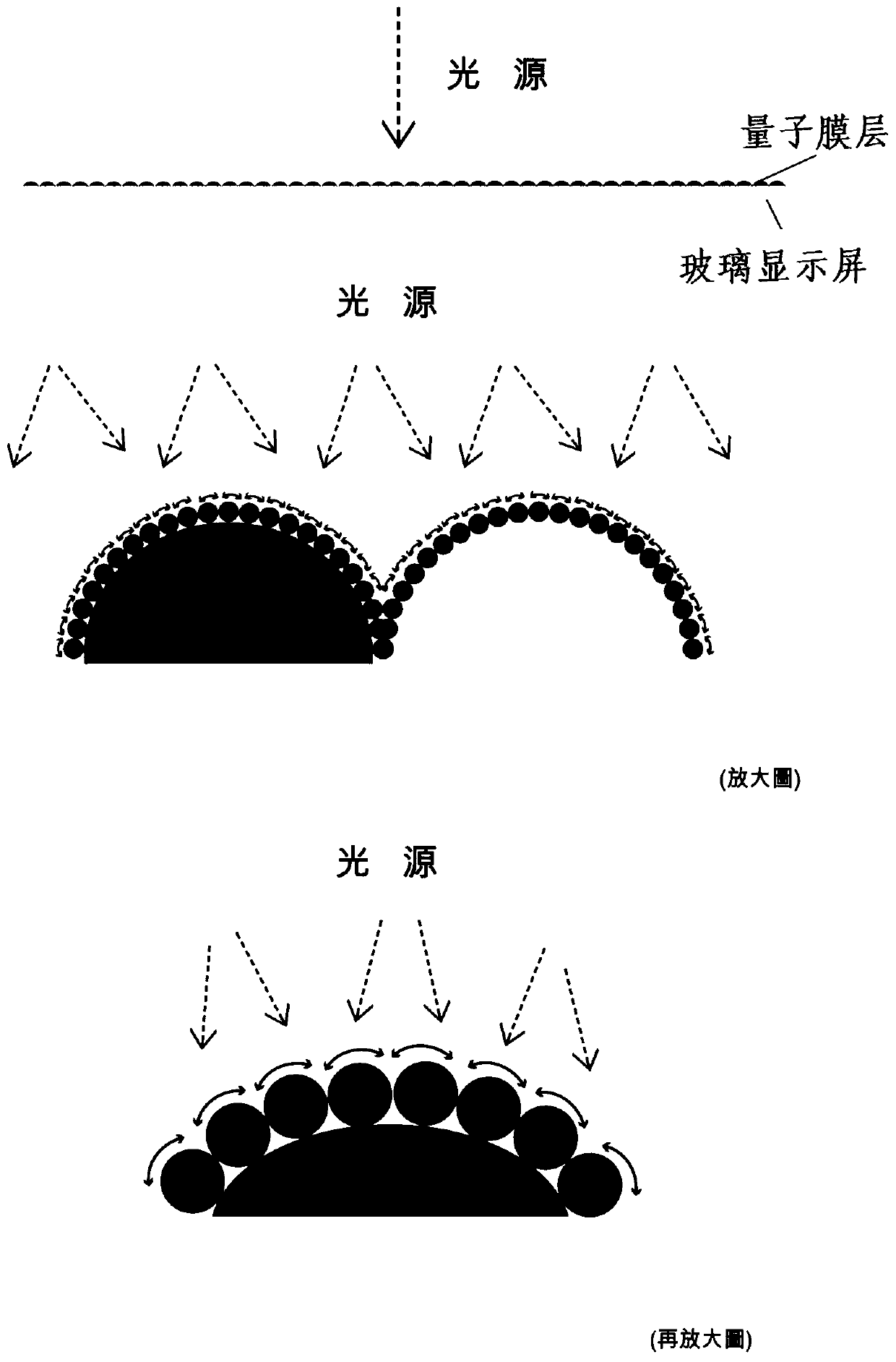

[0026] Such as figure 1 with figure 2 As shown, a glass display screen includes a glass display screen, and a film layer is provided on the glass display screen, and the film layer includes the following components by mass: 30 parts of lead-free glaze, 60 parts of wollastonite, kaolin 20 parts, dolomite 30 parts, calcium carbonate 10 parts, talc 10 parts, zinc silicate 10 parts, silicon dioxide 10 parts, calcite 30 parts, silicon dioxide 10 parts, magnesium oxide 10 parts, sodium citrate 20 parts and Sodium hexametaphosphate 10 parts.

[0027] Wherein, the lead-free glaze includes PbO-SiO2, PbO-SiO2-Al203, PbO-R2O-SiO2-Al203 and PbO-B203-SiO3 system glaze.

[0028] Wherein, the film layer includes a first film layer and a second film layer.

[0029] Wherein, the thicknesses of the first film layer and the second film layer are respectively 20um.

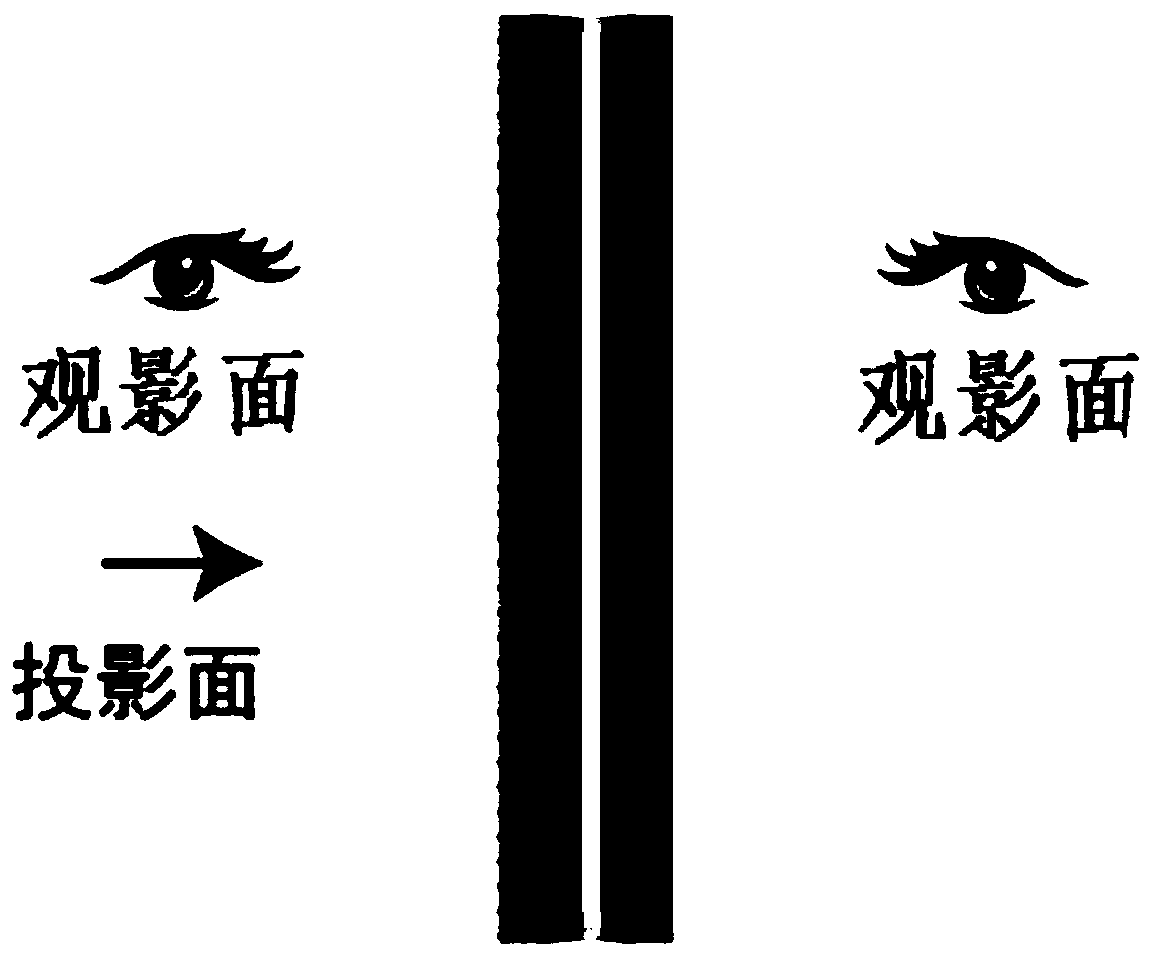

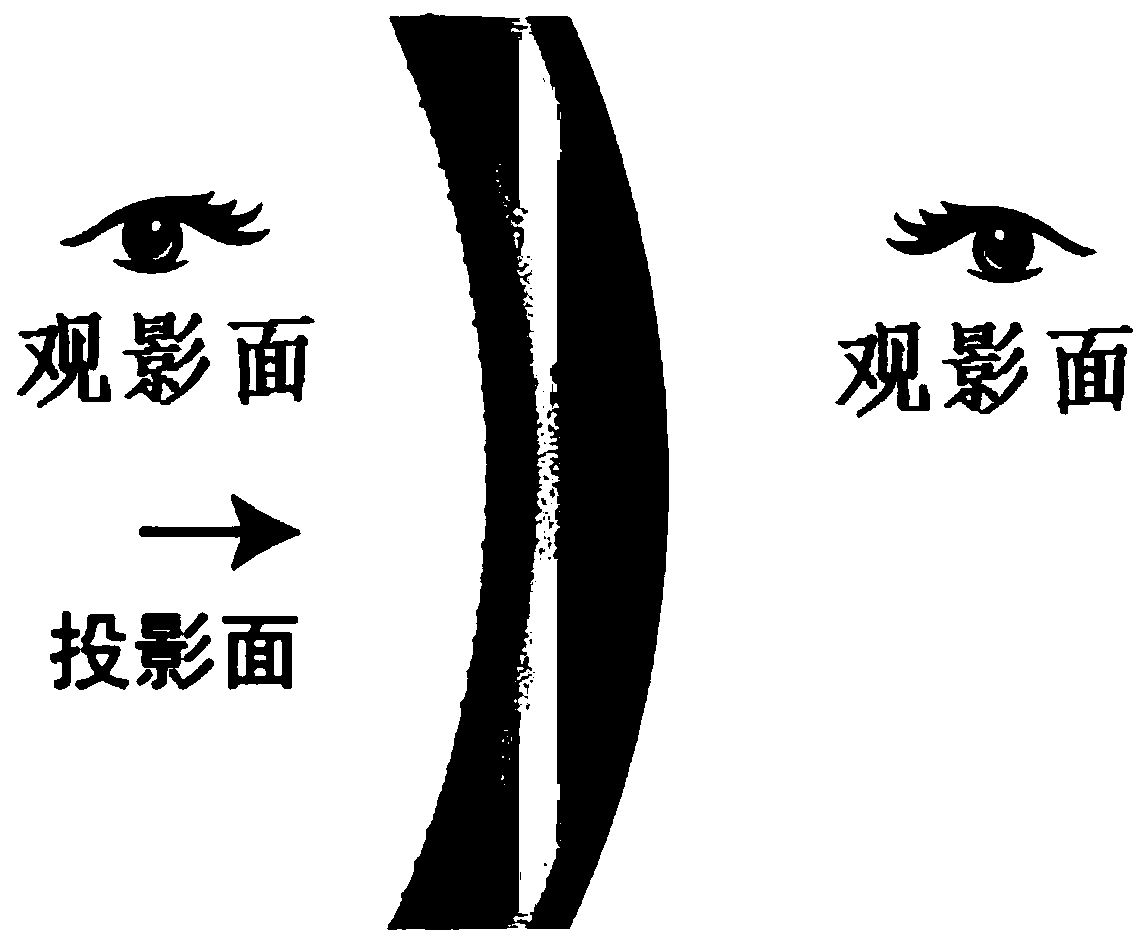

[0030] Wherein, both sides of the glass display screen can be imaged, and the imaging resolution is not damaged.

[0031] A k...

Embodiment 2

[0038] Such as figure 1 with figure 2 As shown, a glass display screen includes a glass display screen, the glass display screen is provided with a film layer, and the film layer includes the following components by mass: 35 parts of lead-free glaze, 50 parts of wollastonite, kaolin 25 parts, dolomite 40 parts, calcium carbonate 20 parts, talc 20 parts, zinc silicate 20 parts, silicon dioxide 13 parts, calcite 35 parts, silicon dioxide 12 parts, magnesium oxide 13 parts, sodium citrate 25 parts and Sodium hexametaphosphate 20 parts.

[0039] Wherein, the lead-free glaze includes PbO-SiO2, PbO-SiO2-Al203, PbO-R2O-SiO2-Al203 and PbO-B203-SiO3 system glaze.

[0040] Wherein, the film layer includes a first film layer and a second film layer.

[0041] Wherein, the thicknesses of the first film layer and the second film layer are respectively 25um.

[0042] Wherein, both sides of the glass display screen can be imaged, and the imaging resolution is not damaged.

[0043] A kin...

Embodiment 3

[0050] Such as figure 1 with figure 2As shown, a glass display screen includes a glass display screen, and a film layer is provided on the glass display screen, and the film layer includes the following components by mass: 40 parts of lead-free glaze, 30 parts of wollastonite, kaolin 30 parts of dolomite, 30 parts of calcium carbonate, 30 parts of talc, 30 parts of zinc silicate, 15 parts of silicon dioxide, 40 parts of calcite, 15 parts of silicon dioxide, 15 parts of magnesium oxide, 30 parts of sodium citrate and 30 parts of sodium hexametaphosphate.

[0051] Wherein, the lead-free glaze includes PbO-SiO2, PbO-SiO2-Al203, PbO-R2O-SiO2-Al203 and PbO-B203-SiO3 system glaze.

[0052] Wherein, the film layer includes a first film layer and a second film layer.

[0053] Wherein, the thicknesses of the first film layer and the second film layer are respectively 30um.

[0054] Wherein, both sides of the glass display screen can be imaged, and the imaging resolution is not dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com