Novel blower equipment

A new type of equipment technology, applied in the field of new grain suction machine equipment, can solve the problems of increasing labor costs, not meeting the needs of production and processing, and low work efficiency, so as to achieve increased functionality, stable equipment operation, and strong functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

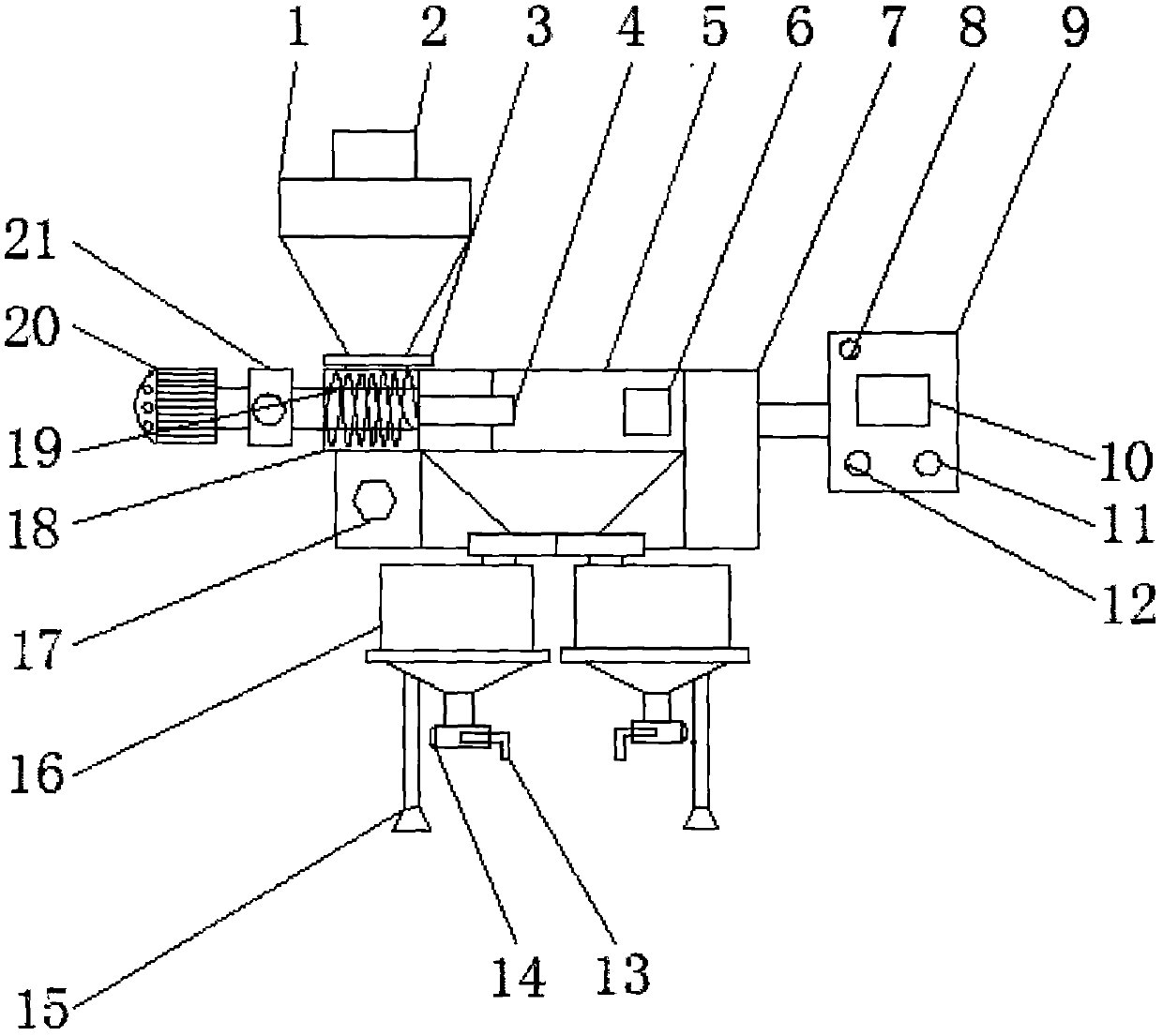

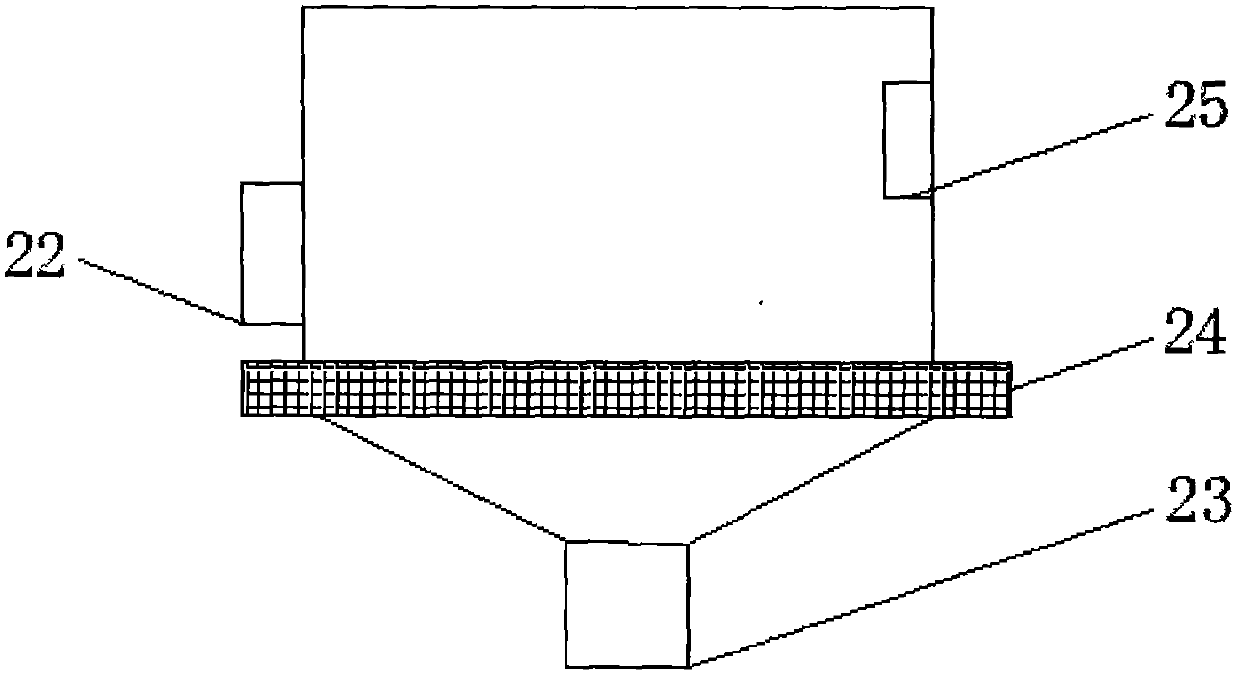

[0015] refer to Figure 1-2 , a new type of grain suction machine equipment, including a feed funnel 1, an anti-clogging device 3, a pressing chamber 5, a control box 9, an oil distribution tank 16, a driving chamber 18, a filter screen 24 and a heat-sensitive conductor 25, and a feed funnel 1 A funnel cover 2 is installed above, an anti-clogging device 3 is installed under the feeding funnel 1, a driving chamber 18 is installed under the anti-clogging device 3, a rotating shaft 19 is arranged inside the driving chamber 18, and a squeezing chamber 5 is installed on the right side of the driving chamber 18. And the drive rod 4 is installed inside the squeezing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com