On-line verification system and method of pilot-operated safety valve

A pilot-operated safety valve and conduction technology, applied in the field of safety valve calibration, can solve the problems of time-consuming and labor-intensive, large-volume pilot-operated safety valve, low working pressure of pilot-operated safety valve, etc. The convenience of the test and the effect of ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

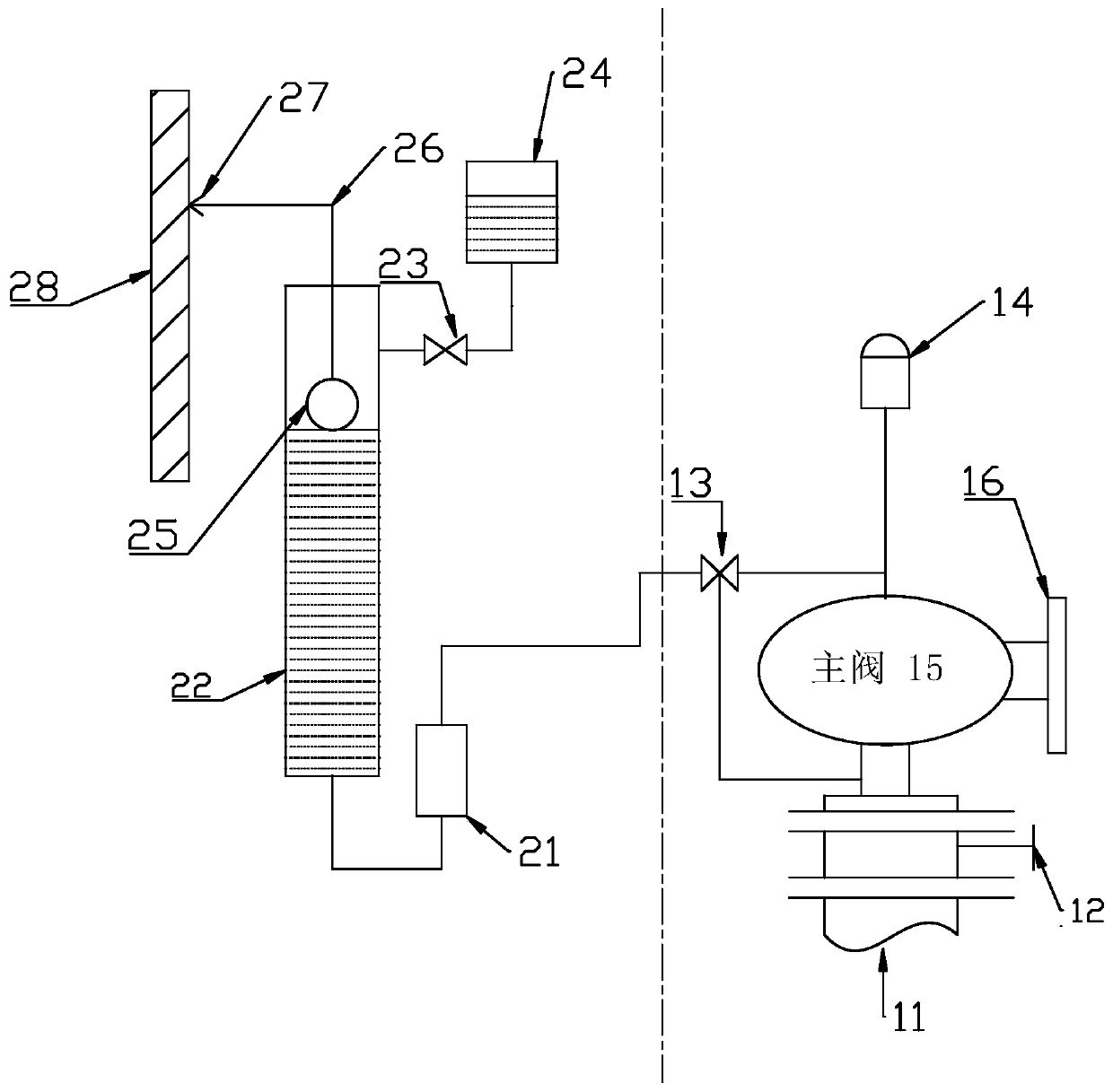

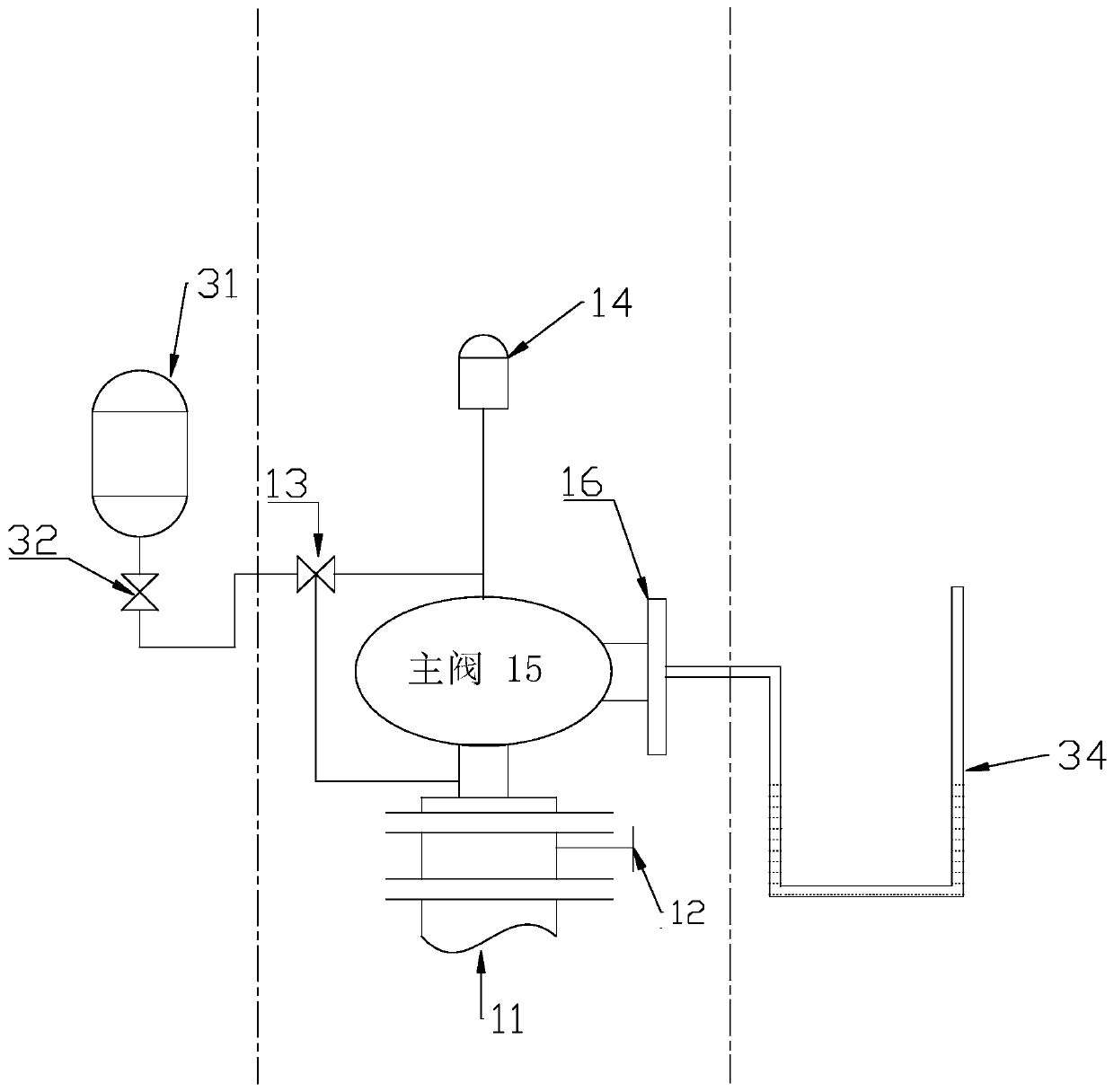

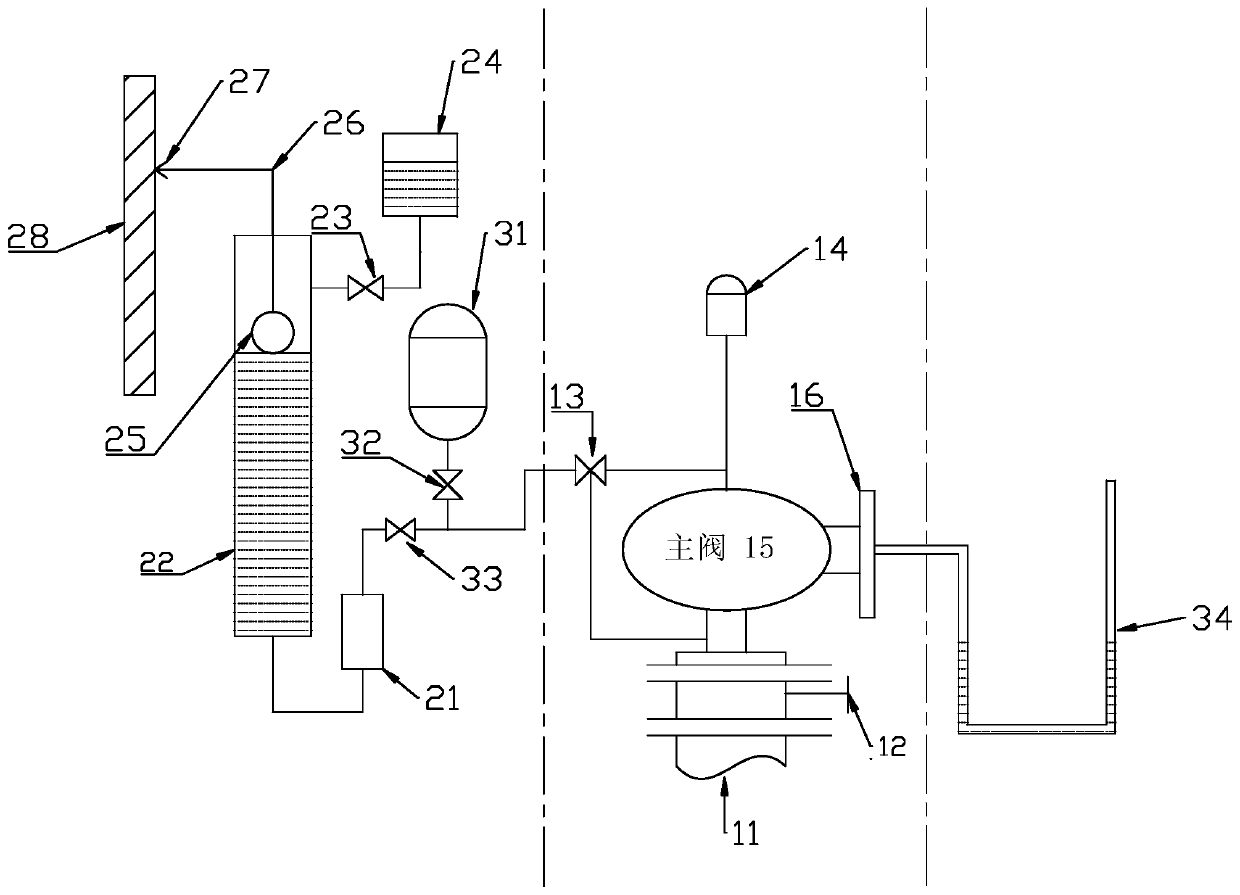

[0069] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0070] 1. Since the pilot-operated safety valve is installed on the top of the tank, the volume of the liquefied natural gas storage tank reaches tens of thousands of cubic meters, and the height of the geometric dimension is as high as tens of meters. For the convenience of on-site calibration, the online calibrator is generally required to be light, the equipment height should not exceed 4 meters, the effective height is 3 meters, and the diameter is reasonable, which is easy to carry and operate on site;

[0071] 2. Due to the low setting pressure of the pilot-operated safety valve, the accuracy and range of the traditional pressure gauge cannot meet the requirements. A reasonable pressure measurement device should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com