Anti-shock device for hydraulic support

A technology of hydraulic support and anti-shock device, which is applied in the direction of pillars/supports, mining equipment, earthwork drilling and mining, etc. It can solve the problem that the impact energy cannot be released, the production cycle is long, and it must go through several production cycles to return to normal Mining height and other issues to achieve the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

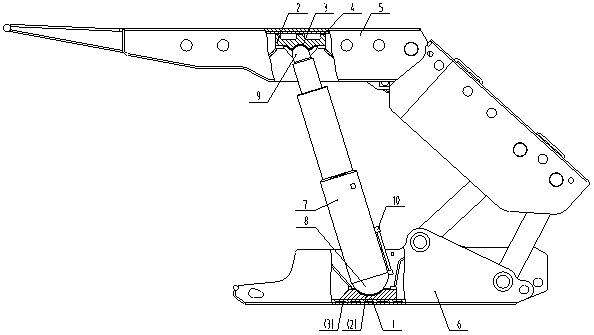

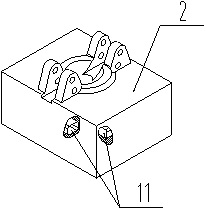

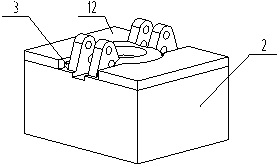

[0014] like figure 1 As shown, a hydraulic support anti-shock device is mainly used for the protection of the hydraulic support on the working face, including the column socket (1), the column cap (2), the energy-absorbing anti-shock protection pad (3) and the energy-absorbing filling fluid (4) , when the hydraulic support is impacted by the top and bottom plates during the support process, at the moment when the safety valve (10) of the column (7) is too late to open, the energy-absorbing anti-shock protection pad (2) will instantly harden, and the energy-absorbing anti-shock The protective pad (2) is a composite material made of a high strain rate sensitive material and an auxetic material, and the high strain rate sensitive material reacts quickly to the impact, and its reaction time is shorter than that of the column (7) safety valve (10) The openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com