Fabricated inner partition module

A prefabricated, inner partition wall technology, applied in the direction of walls, sound insulation, insulating layers, etc., can solve the problems of complicated construction period, and achieve the effect of solving the complex construction period, convenient and fast installation, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

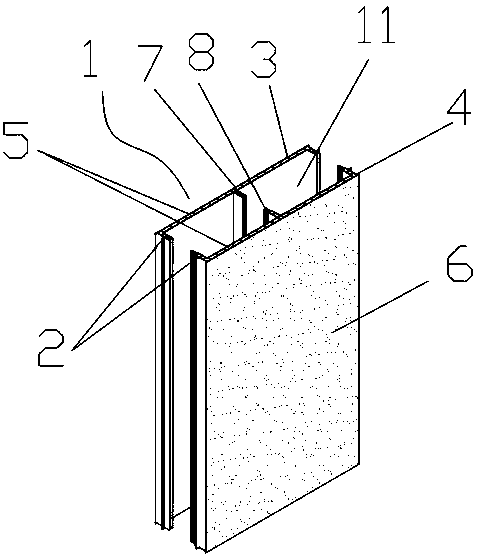

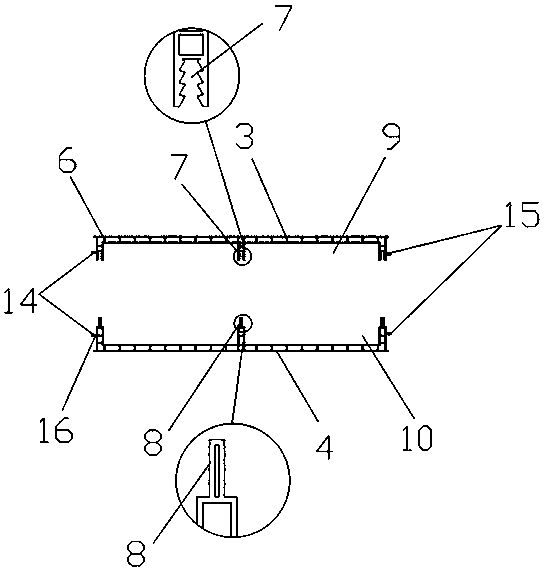

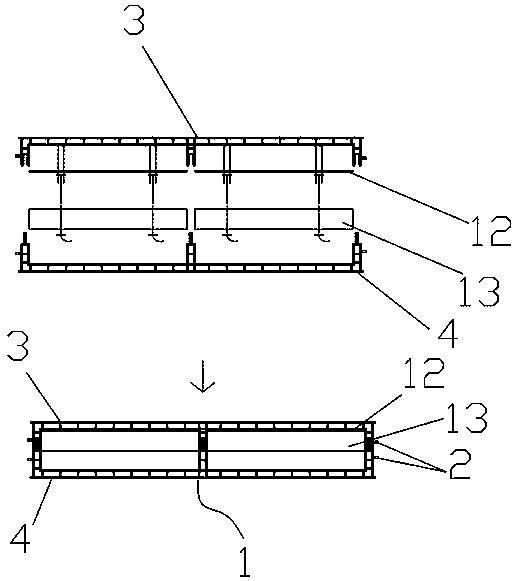

[0025] exist figure 1 , figure 2 , image 3 In the shown embodiment, a prefabricated inner partition wall module includes a buckle-mounted partition wall module body 1, and the two sides of the partition wall module body 1 are respectively provided with two adjacent groups of partition wall module bodies 1 that are inserted into each other. The connected module buckle structure 2; the partition wall module body 1 includes a partition wall mother board 3 and a partition wall male board 4 which are connected with each other by plugging and buckling.

[0026] Cavities 5 are respectively provided inside the partition wall mother board 3 and the partition wall male board 4 .

[0027] The partition wall mother board 3 and the partition wall male board 4 are respectively extruded stone-plastic boards, and the outer surfaces of the partition wall mother board 3 and the partition wall male board 4 are respectively provided with a coating layer 6 .

[0028] A plurality of tooth groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com