Small-size opening conveying type gasket numerical control cutting machine

A conveyor type, cutting machine technology, applied in small raw hides/large raw hides/leather/fur mechanical processing, leather punching/punching/cutting, small raw hides/large raw hides/leather/fur processing, etc. problems such as poor performance, high cost, and low precision, to achieve the effect of improving mobility and site adaptability and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

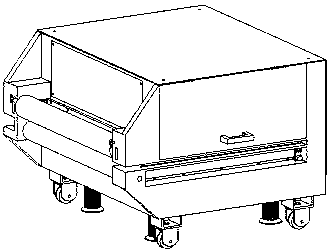

[0032] Such as figure 1 As shown, the small opening conveying type gasket CNC cutting machine includes a box module 100 , a conveying and clamping module 200 , a tensioning module 300 , a cutting movement module 400 , and a scrap cutting module 500 .

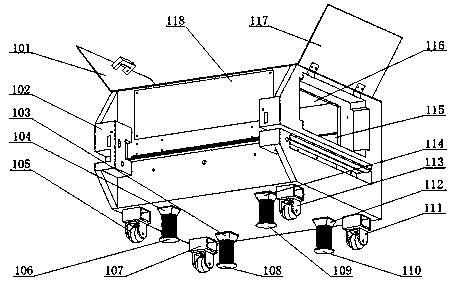

[0033] Such as figure 2 The box module 100 shown is characterized in that: universal wheel mounting holes are designed at the bottom of the box main body 102, four mounting holes are symmetrically distributed at the bottom of the box body main body 102, universal wheel one 105, universal wheel two 107. Three universal wheels 111 and four universal wheels 113 are installed on the bottom of the box main body 102 with screws respectively. The bottom of the box main body 102 is designed with fixing grooves for foot mounting seats, and the four fixing grooves are symmetrically distributed at the bottom of the box body 102. Leg mounting seat 1 104, leg mounting seat 2 103, leg mounting seat 3 112, leg mounting seat 4 114 are set in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com