LCD glass cutting system

A glass cutting and glass technology, applied in glass cutting devices, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of low degree of automation and continuity, low work efficiency, prone to errors, etc., to save labor costs, The structure is simple, reasonable and reliable, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

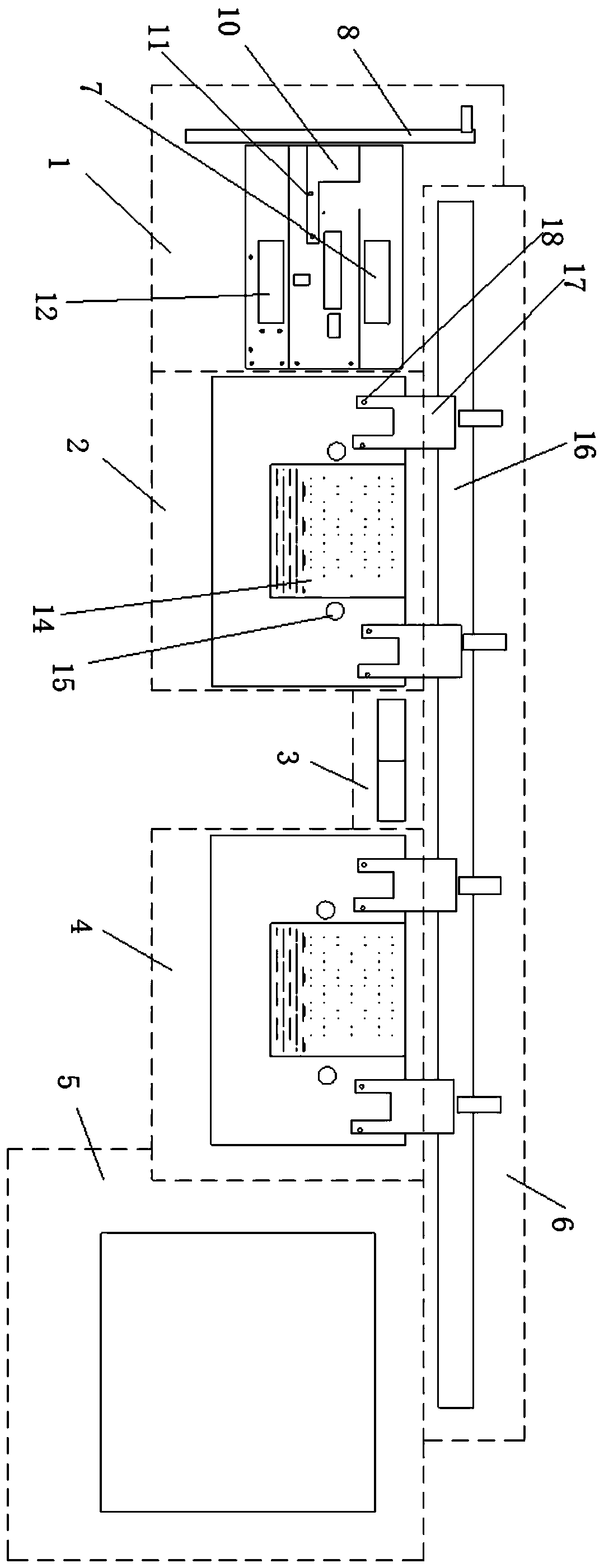

[0028] Examples such as Figure 1 to Figure 11 An LCD glass cutting system is shown, including a frame 110. The frame 110 is sequentially provided with a feeding mechanism 1, a front cutting mechanism 2, a turning mechanism 3, a reverse cutting mechanism 4, and a material collection mechanism from the feeding end to the discharging end. 5. The frame 110 is also provided with a transport mechanism 6 for sequentially transporting the LCD glass from the feeding mechanism 1 to the front cutting mechanism 2 , the turning mechanism 3 , the back cutting mechanism 4 , and the collecting mechanism 5 . The front cutting mechanism 2 is used for half-cutting the front of the LCD glass, and the rear cutting mechanism 4 is used for half-cutting the back side of the LCD glass, and the cutting of the LCD glass is realized through cooperation of the two.

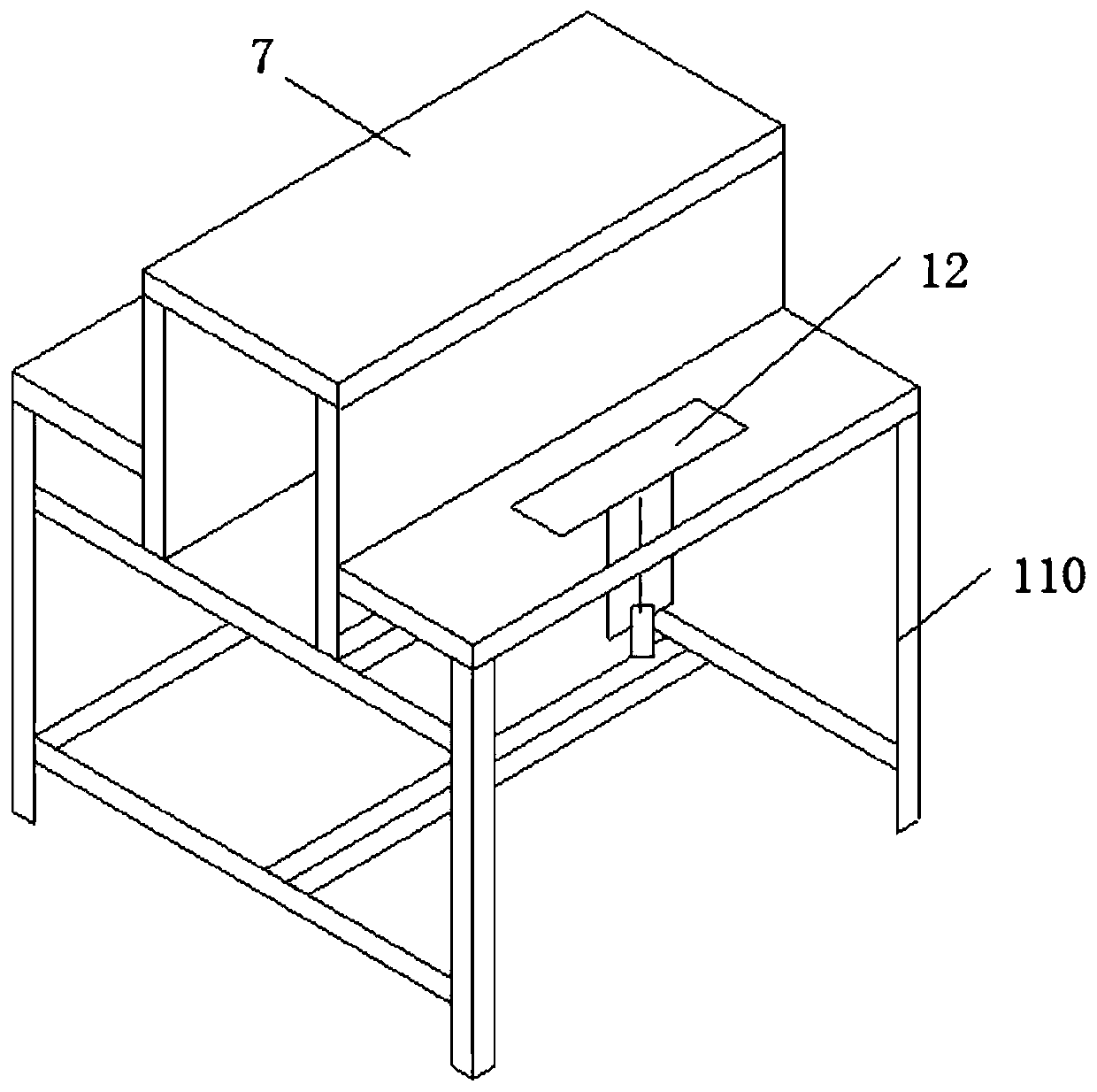

[0029]Described feeding mechanism 1 comprises the feeding platform 7 that is arranged on the frame 110 and feeding driving mechanism, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com