Marine low-speed diesel engine cross-head pin cylindrical surface notch positioning tool and positioning method

A crosshead pin and positioning tooling technology, which is applied in the field of metal cutting, can solve the problems of time-consuming, labor-intensive, low efficiency, and increased processing errors, and achieve the effects of improving production efficiency, reducing processing costs, and saving driving and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and the positioning tool and positioning method of the crosshead pin cylindrical notch of a certain type of marine low-speed diesel engine.

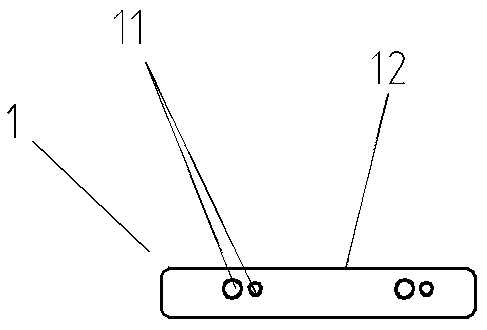

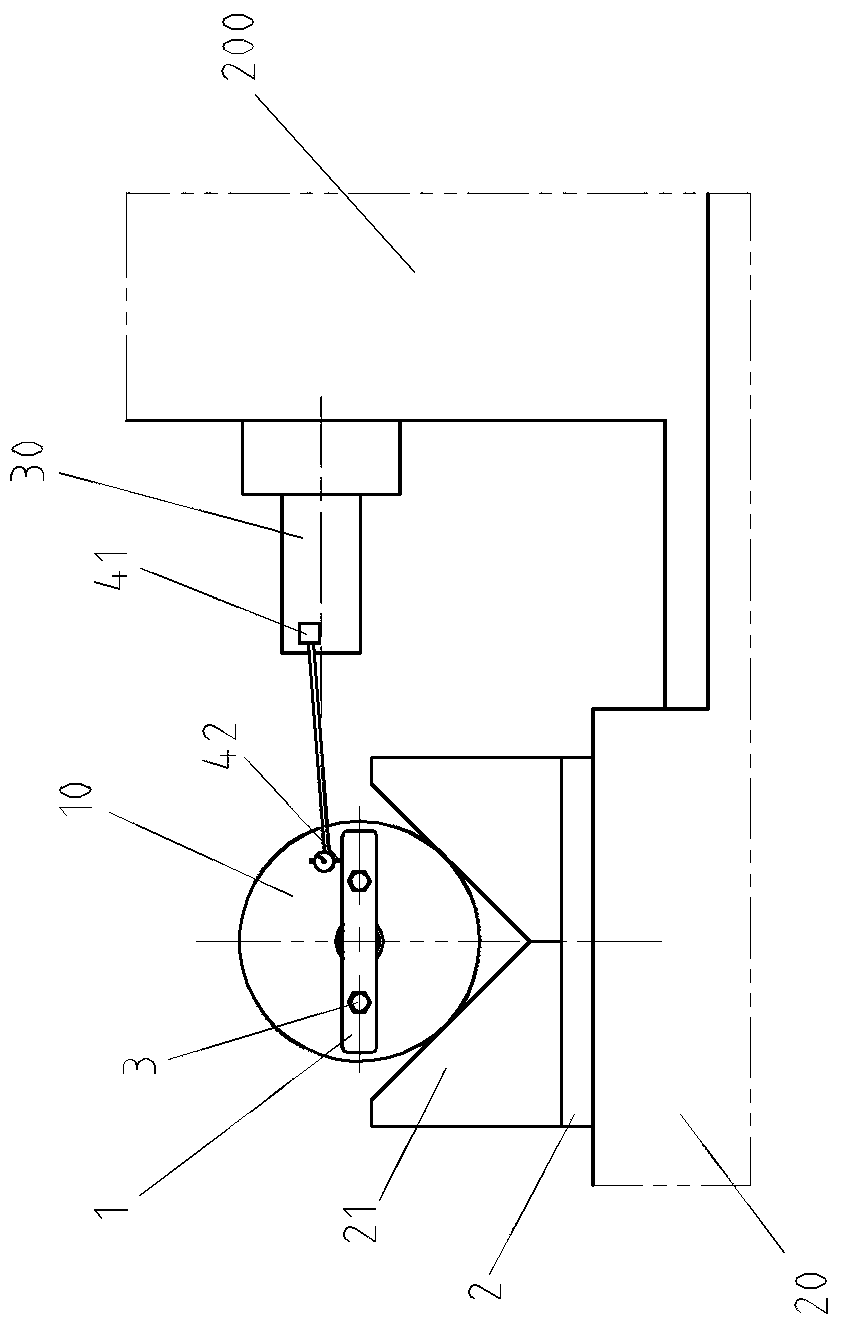

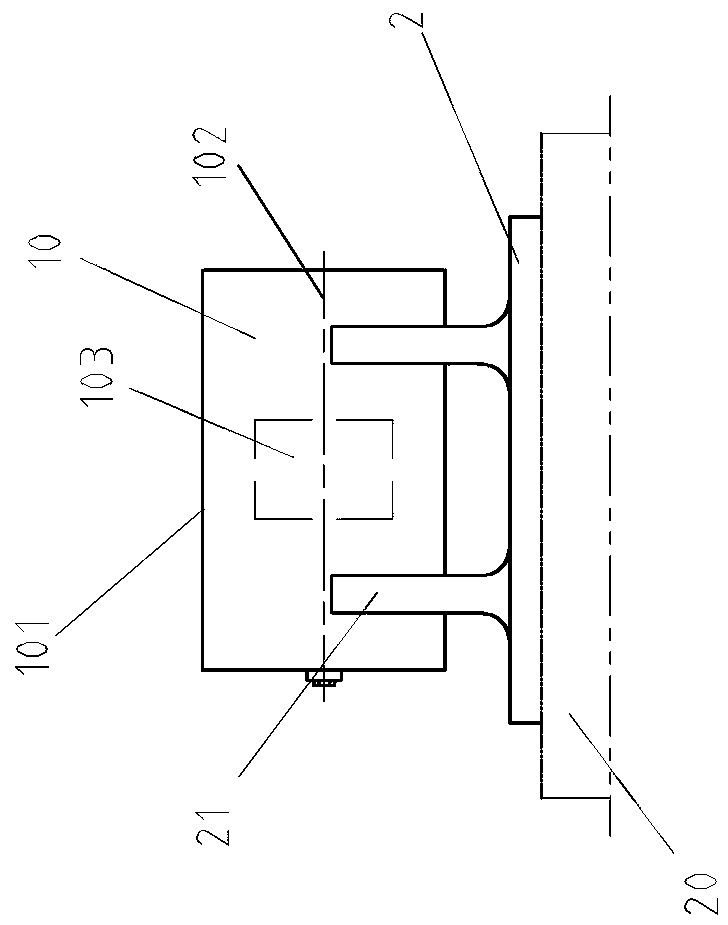

[0025] Such as Figure 1 to Figure 4 As shown, the positioning tool of this embodiment is a strip-shaped positioning plate 1, and the positioning plate is longitudinally provided with two sets of hinged holes 11, which can be used for crosshead pins 10 of two types. Each group of two reaming holes 11 is respectively matched with the lifting screw hole of the crosshead pin of the corresponding model. The size of the crosshead pin 10 in this embodiment is Φ400mm×600mm, and the size of the positioning plate 1 is 400mm×60mm×10mm. The surface roughness of the side 12 on the positioning plate is Ra=0.8μm~1.6μm, and the flatness tolerance of the side 12 on the positioning plate is ≤0.02mm, which improves the measurement reference accuracy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com