Automatic mineral separation equipment for tungsten ore refining

An automatic and equipment technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of weak refining, difficulty in obtaining satisfactory beneficiation technical indicators, and reduction in concentrate quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

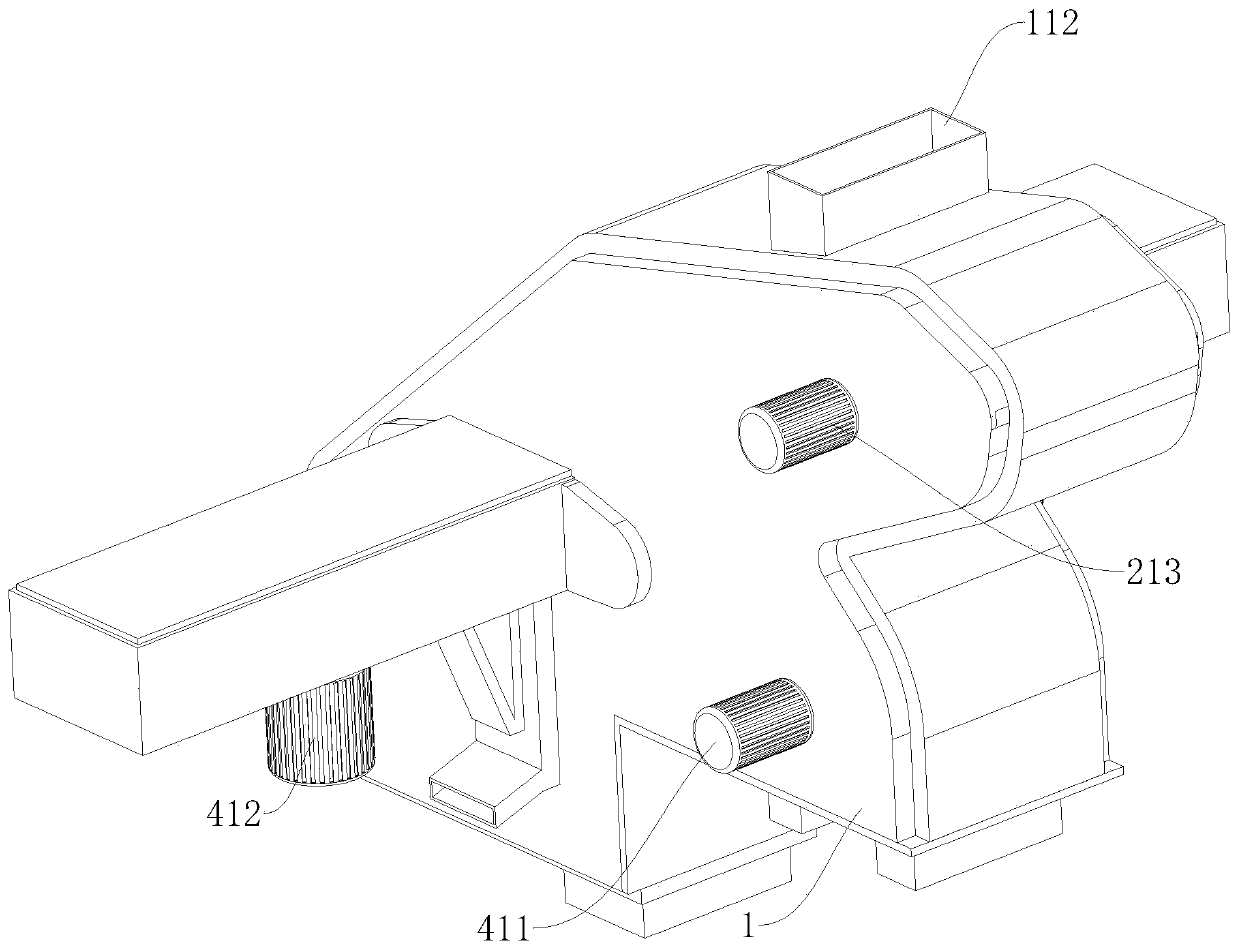

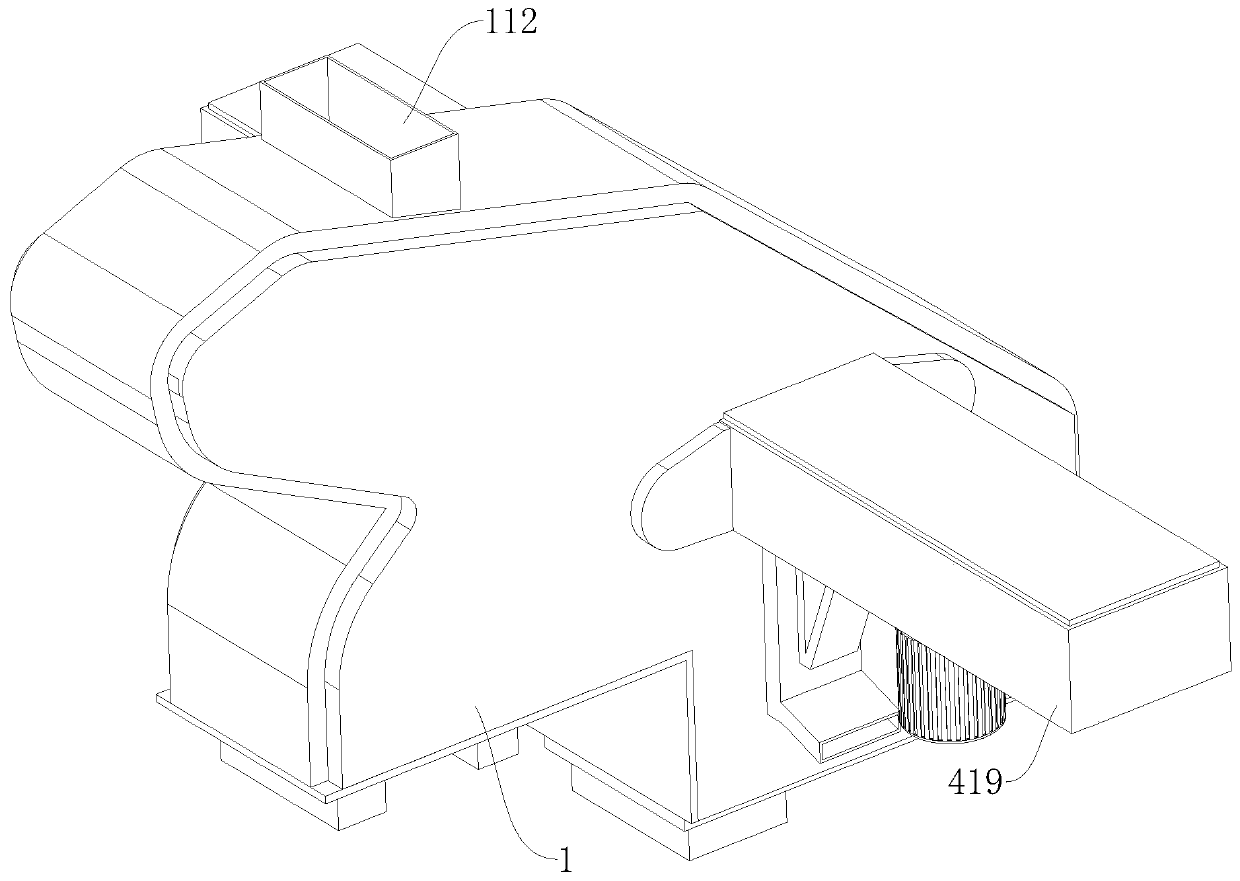

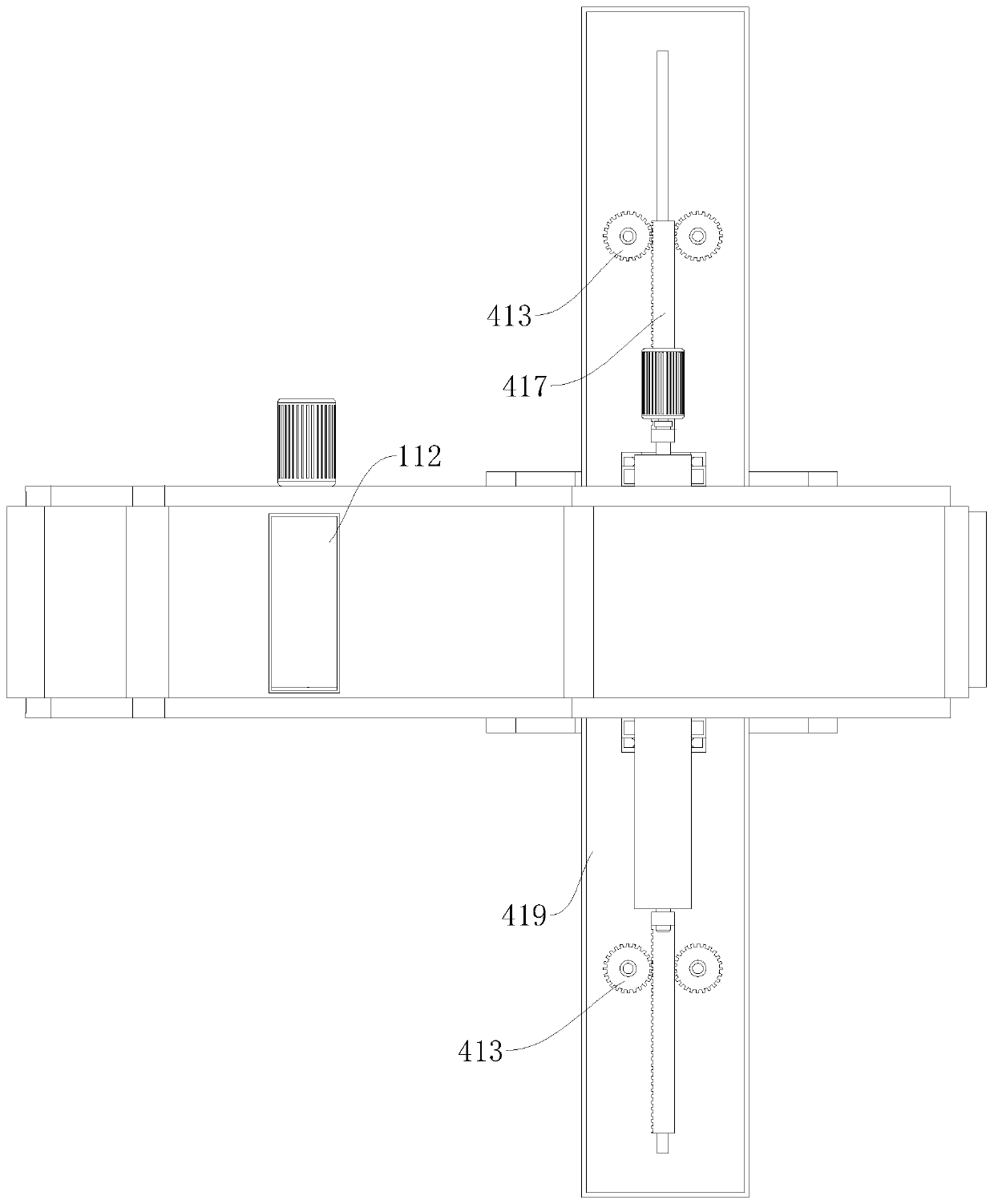

[0036] Reference Figure 1 to Figure 11 The automatic ore dressing equipment for tungsten ore refinement shown includes a main box 1, a coarse screen mechanism 2 and a first fine screen magnetic roller 4. The top of the main box 1 is provided with a ore feeding hopper 112, a coarse screen The mechanism 2 is arranged in the main box 1, and is located under the feeding hopper in an inclined posture. The screening end of the coarse screen mechanism 2 is inclined downward, and the first fine screen magnetic roller 4 is located below the screening end of the coarse screen mechanism 2. A re-screening mechanism 9 parallel to the coarse-screening mechanism 2 is provided below a fine-screening magnetic roller 4, the screening end of the re-screening mechanism 9 is inclined downward, and a second fine-screening magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com