A method for evaluating the consistency of processing strength of shredded shreds during drum drying based on the heating process of shredded shreds

A drum drying and drying process technology is applied in the field of evaluating the consistency of the processing strength of the drum drying process based on the heating process of the leaf fiber, which can solve the problem of not systematically analyzing the heating process of the drum drying leaf fiber, and does not involve the moisture content of the drying kinetic material. and other problems, to achieve the effect of reducing instability and low reproducibility, simple calculation process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

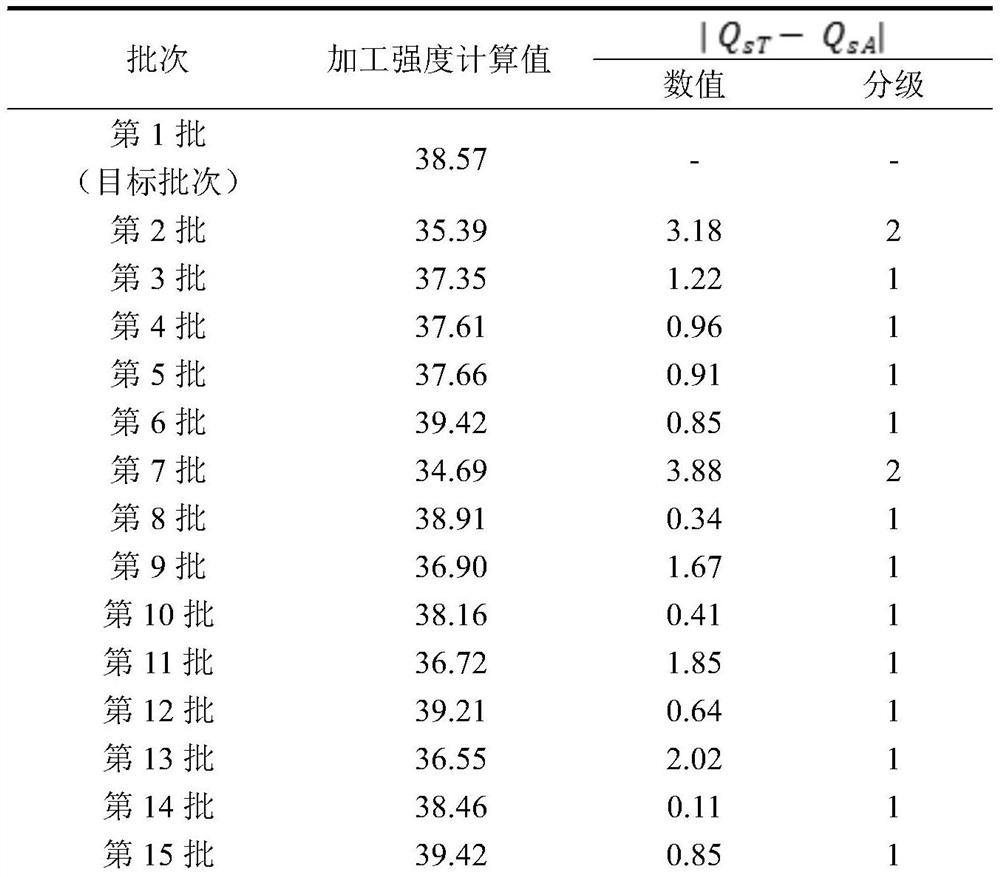

Embodiment 1

[0030] In Example 1, a certain brand of shredded tobacco with modular formula was used for production. Under the condition of constant drum equipment and processing conditions, 27 batches of drum-dried inner shredded tobacco surface temperature data were continuously measured. To evaluate the consistency of the processing strength index of different batches of drum-dried leaf shreds. The drum processing conditions are as follows: Process flow rate G: 5140.00kg absolute dry material / h, cylinder wall temperature in zone one: 155.00℃, cylinder wall temperature in zone two: 145.00℃, hot air temperature 120.00℃.

[0031] (Remarks: The shredded leaf drying equipment in the cigarette manufacturing industry is mainly tube-plate drum drying equipment. With the continuous upgrading of drying equipment and more perfect functions, the processing mode of drum wall temperature zone control of drum drying equipment has appeared in the cigarette manufacturing industry. That is to say, the ori...

Embodiment 2

[0051] This embodiment 2 selects a representative multi-point processing module formula of a certain brand, and measures the surface temperature data of the leaf silk in the drying drums of A factory, B factory, and C factory under different drum drying equipment and different processing conditions, and evaluates the multi-point processing of a certain brand. Consistency of the processing strength index of the point-processed roller-dried leaf shreds, in which each roller was tested three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com