Waterproof single-layer lining structure and construction technology thereof

A construction technique and waterproof technology, which can be applied in the shaft lining, tunnel lining, underground chamber, etc., and can solve the problems of not meeting the waterproof requirements, waterproof and anti-seepage treatment of a single waterproof coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

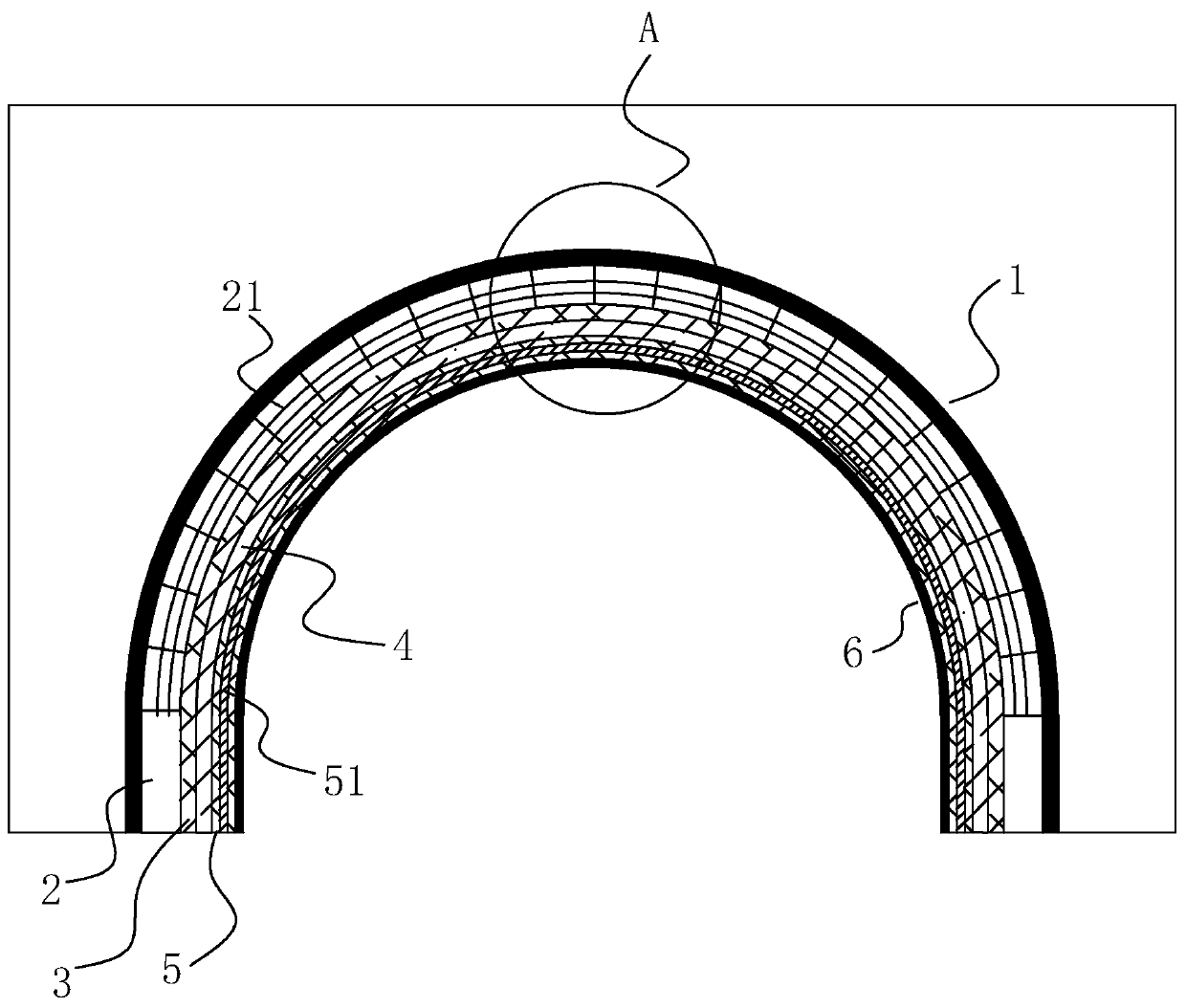

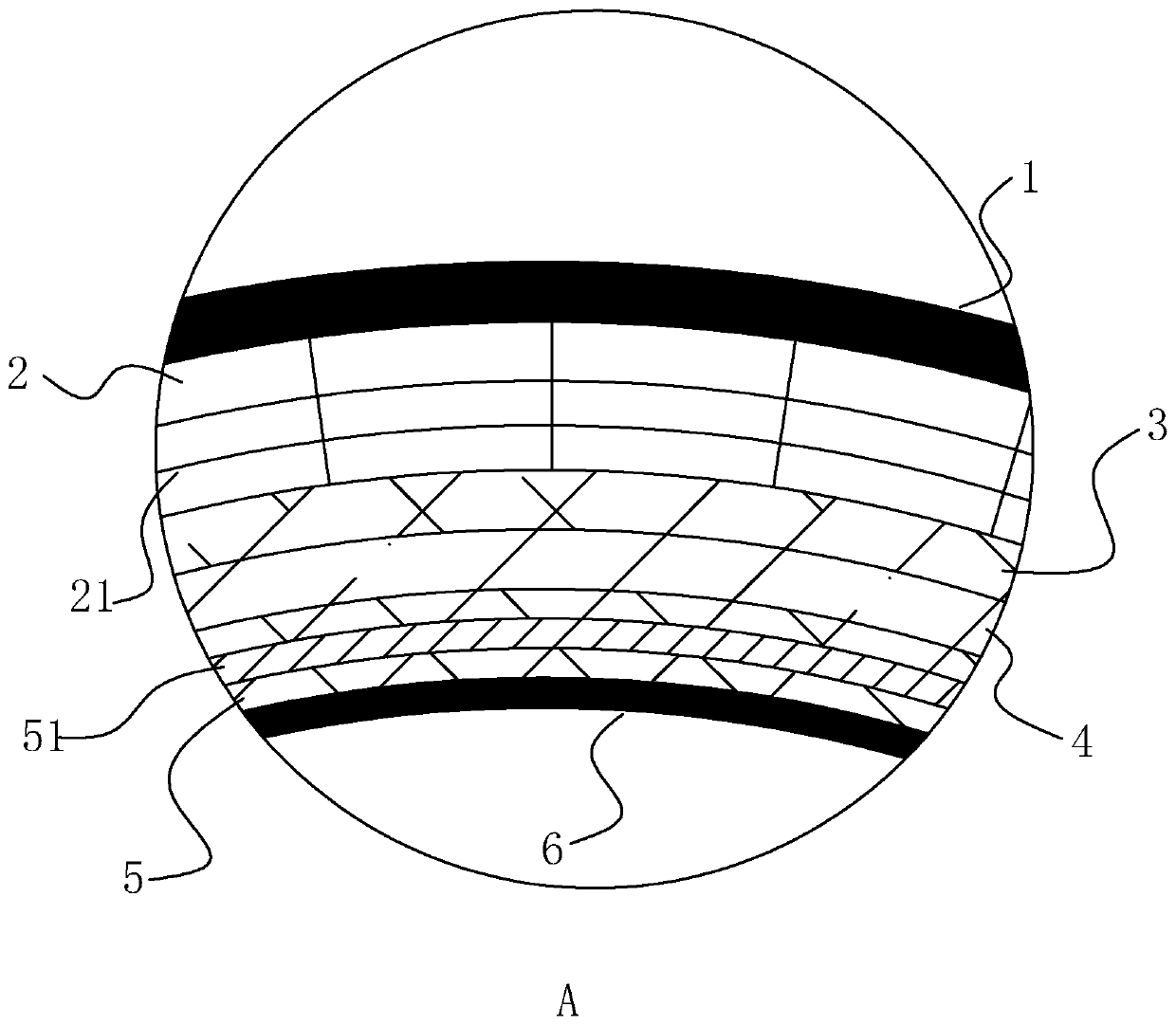

[0037] Example 1: A waterproof single-layer lining structure, refer to figure 1 with figure 2 , Including a base concrete layer 1, a supporting concrete layer 2, a waterproof isolation layer 3, a reinforced concrete layer 4, a waterproof concrete layer 5 and a nano-coating layer 6 arranged in sequence from the arched structure close to the tunnel body to the surface side. The supporting concrete layer 2 is provided with a reinforcing steel skeleton 21; the waterproof isolation layer 3 is made of corrosion-resistant metal. The waterproof concrete layer 5 is formed by grouting with waterproof concrete slurry, and a waterproof cloth 51 is arranged in the waterproof concrete layer 5. Wire meshes are respectively provided on the side of the steel reinforcement skeleton 21 close to the arch structure of the tunnel main body and the side away from the arch structure of the tunnel main body.

[0038] The base concrete layer 1 is mainly used for smoothing and shaping the structure of the...

Embodiment 2

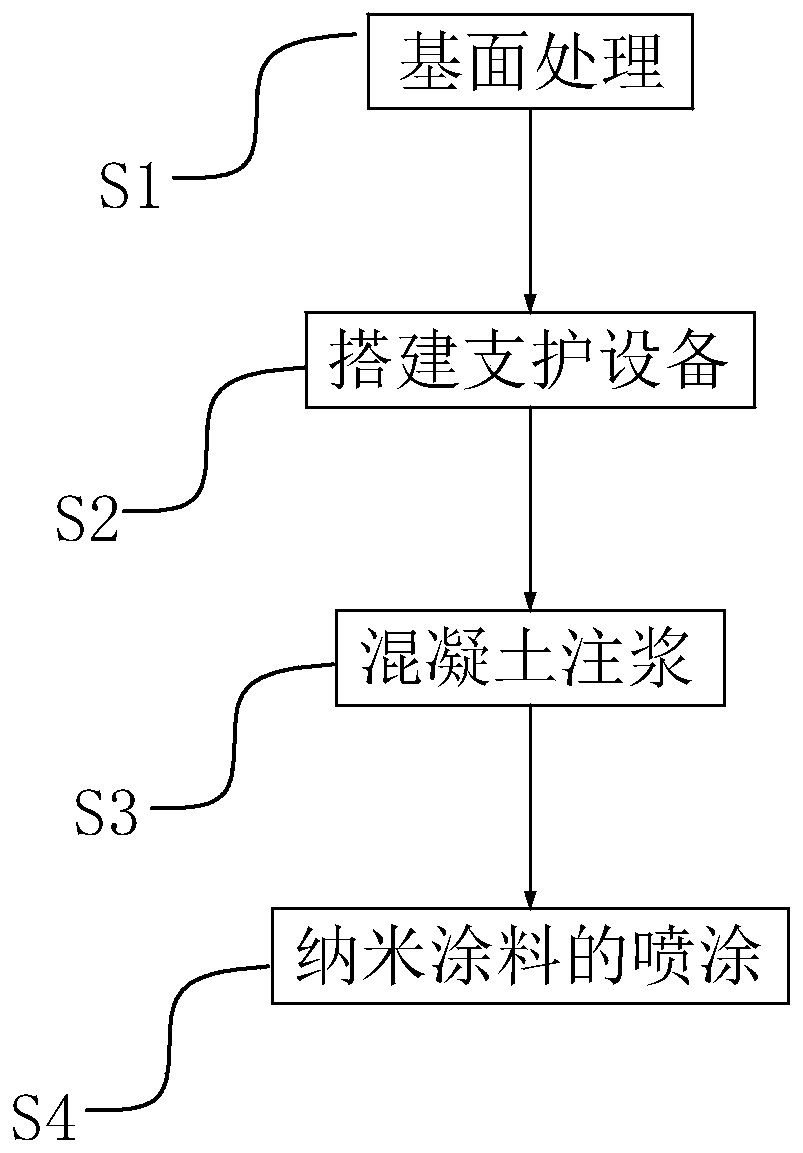

[0039] Example 2: A waterproof single-layer lining structure construction technology, refer to figure 2 , Including the following method steps: step S1, base surface treatment; step S2, building support equipment; step S3, concrete grouting, step S4, spraying of nano paint.

[0040] Step S1, base surface processing. According to the technical requirements of the construction, the surface of the underground tunnel shall be leveled to keep it smooth and flat. According to the monitoring value, the settlement of the vault tends to be stable. After the tunnel clearance meets the requirements through measurement and inspection, the treatment of the base surface should be solid, smooth, and smooth, without obvious unevenness. When the mining method structure, foundation, foundation or load changes, which may cause large differential settlement, deformation joints should be set. Deformation joints are set in this section according to the section changeover, and the width of the deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com