Underground Diaphragm Wall Joint Waterproof Structure and Its Construction Method

A technology for underground diaphragm walls and waterproof structures, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as water-stop and anti-seepage difficulties, and achieve the goals of preventing groundwater infiltration, prolonging the seepage path, and preventing collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The waterproof structure in the present invention will be described in detail below in conjunction with specific embodiments.

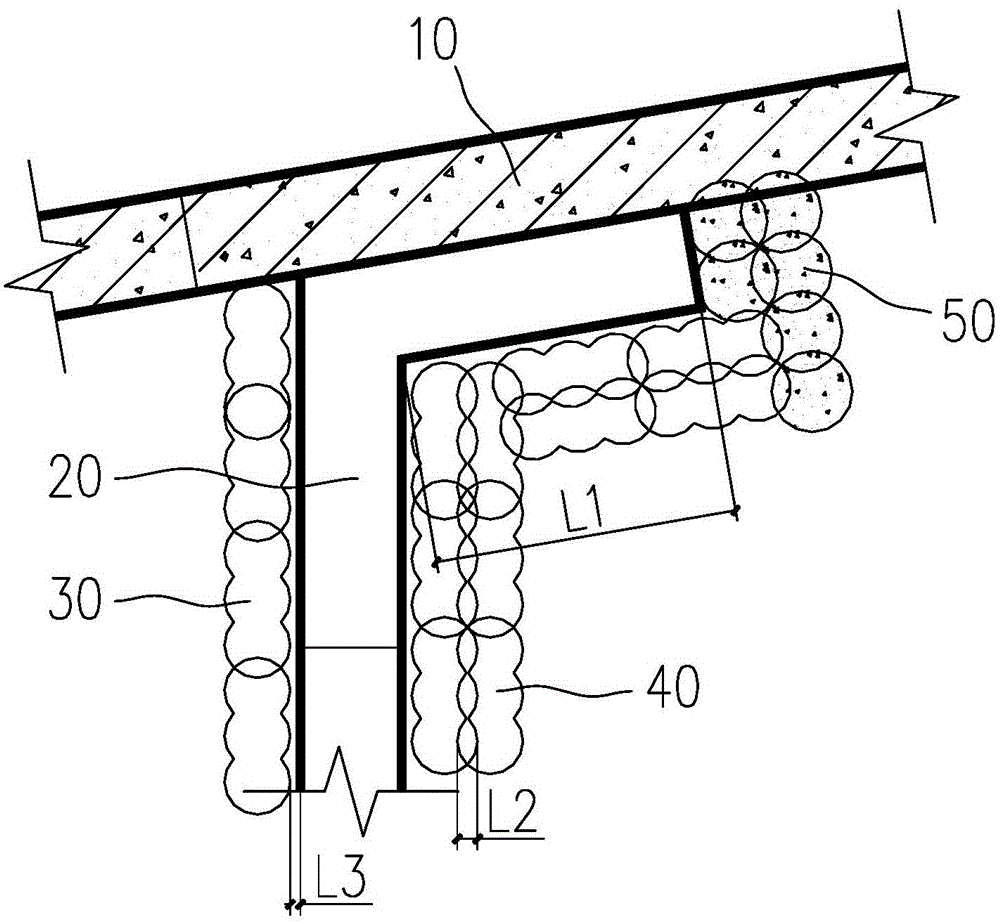

[0030] Such as figure 1 As shown, the waterproof structure includes a first underground continuous wall 10 and a second underground continuous wall 20 that intersect with each other, wherein the first underground continuous wall 10 is the underground continuous wall that is constructed first, and the second underground continuous wall 20 is the latter. Construction of the Diaphragm Wall.

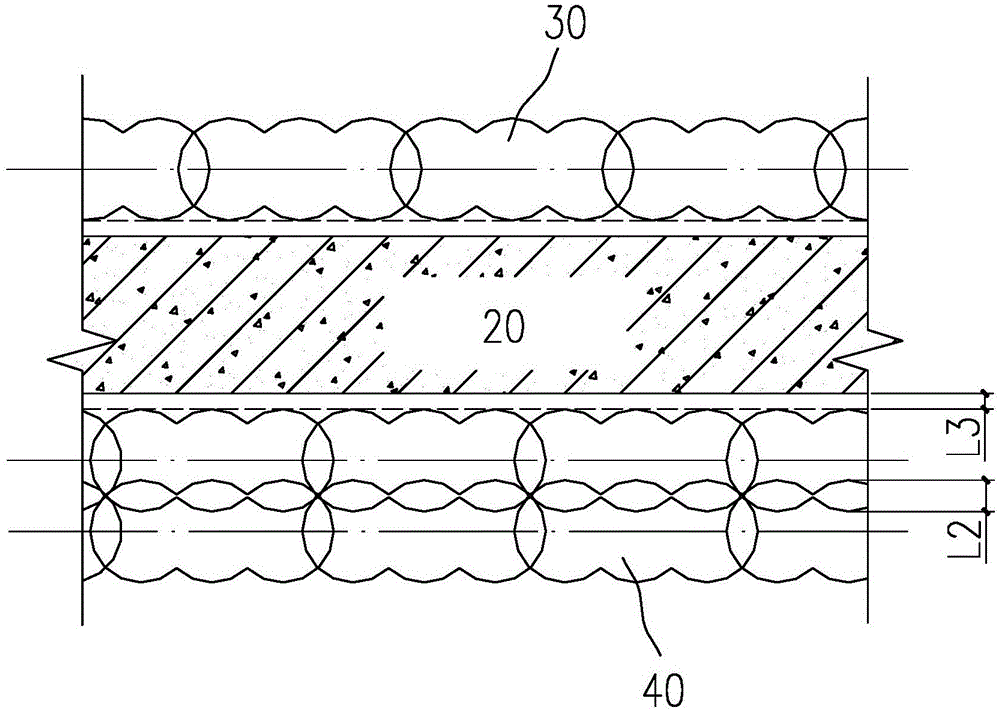

[0031] The end of the second underground continuous wall 20 connected with the first underground continuous wall 10 is provided with a straight bent section, and the bent section extends toward the outside of the pit, and the bent section is connected to the first underground continuous wall. 10 close together; the wall of the second underground continuous wall 20 towards the inner side of the pit is provided with a single row of three-axis mixing piles 30 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com