Safety lining cloth with excellent moisture transferring and heat conducting performance and production process thereof

A technology of thermal conductivity and safety lining, applied in the field of safety lining and its production process, can solve the problems of poor moisture and air permeability and thermal conductivity of lining, easy puncture of monofilament, poor wearing comfort of lining, etc., so as to improve heat conduction and heat dissipation. Ability, guarantee work efficiency, and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the production process of the above-mentioned safety interlining, the safety interlining with excellent moisture-conducting and heat-conducting properties is prepared, comprising the following steps:

[0034] S1: Preparation of composite adhesive, according to the mass ratio of 70 parts of hot melt adhesive, 8 parts of Teflon and 4 parts of nano-graphene oxide, a composite adhesive solution was prepared;

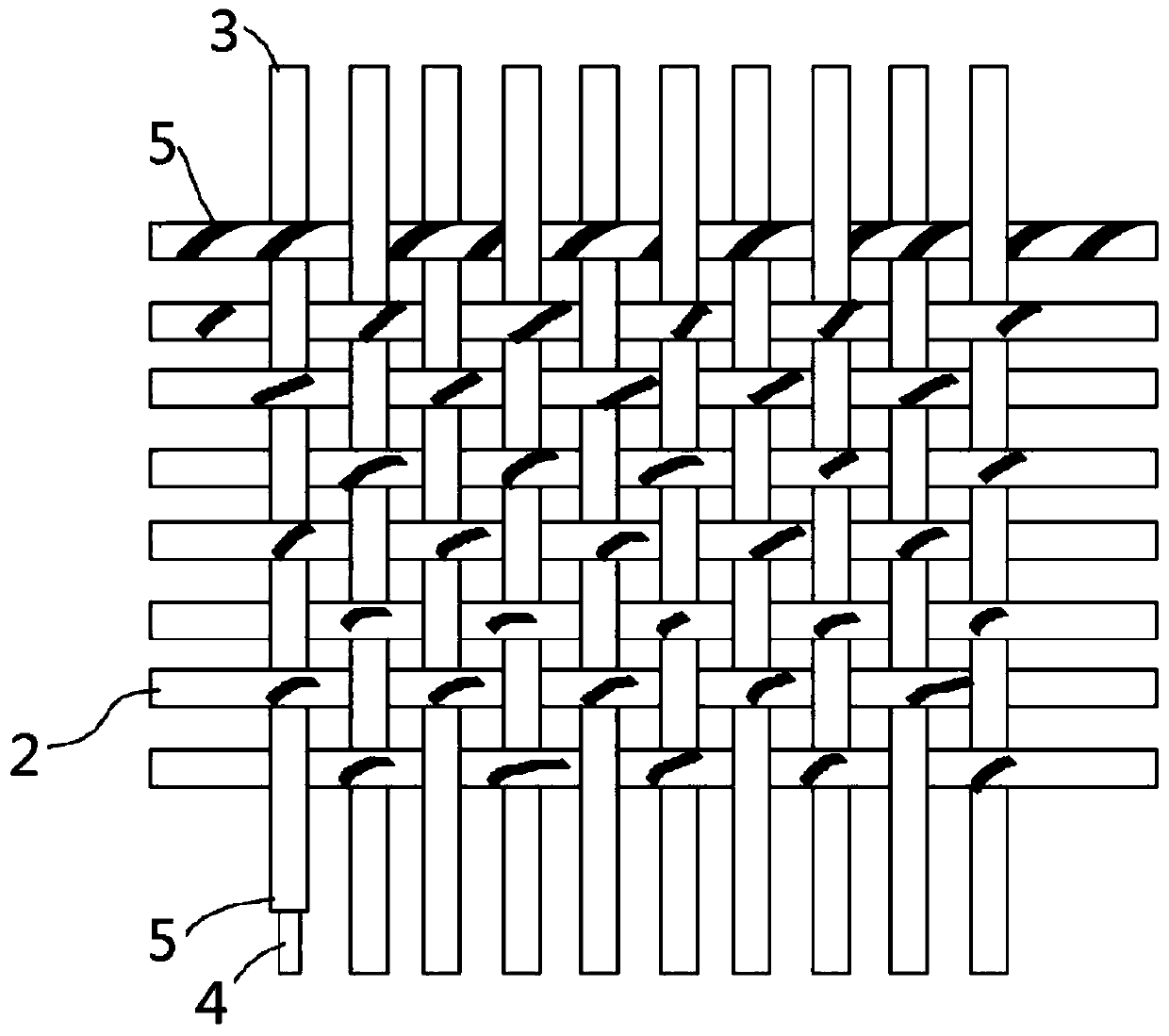

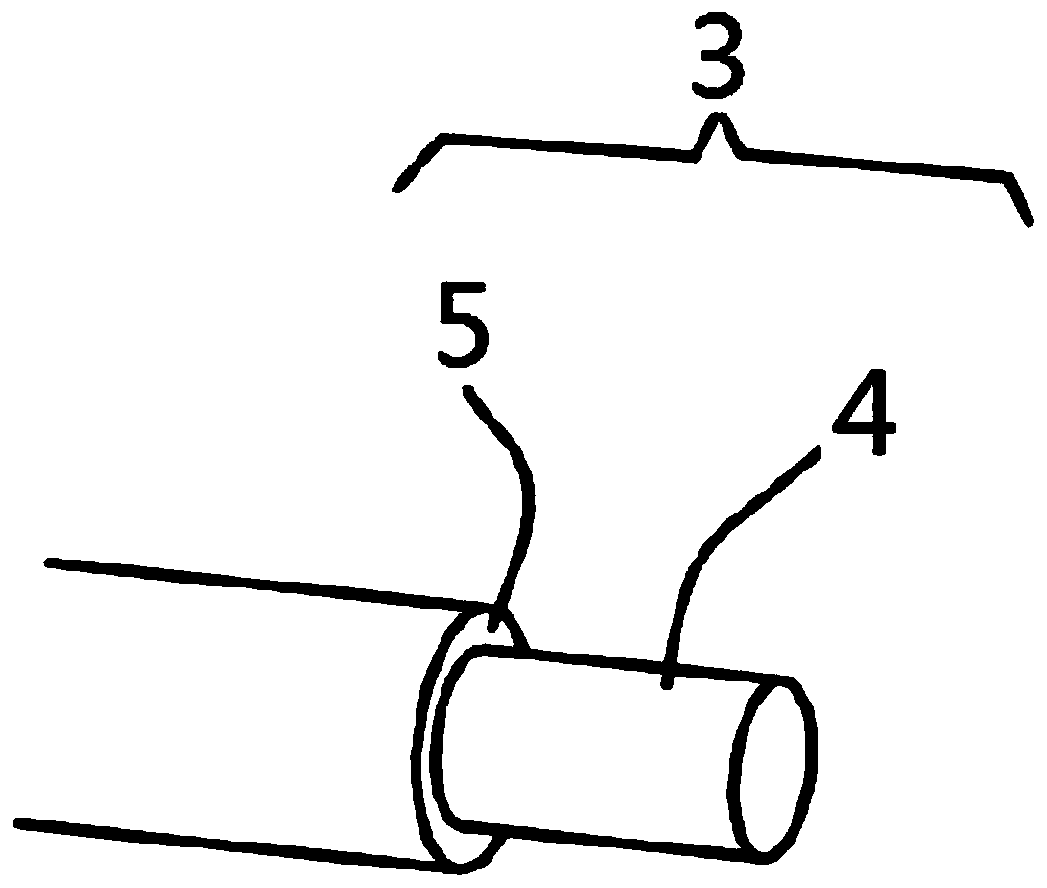

[0035] S2: Yarn making, weaving the above-mentioned warp yarn and weft yarn, soaking the weft yarn into the composite adhesive in the step S1, and then drying to obtain the weft yarn whose outer surface is covered with a composite adhesive layer;

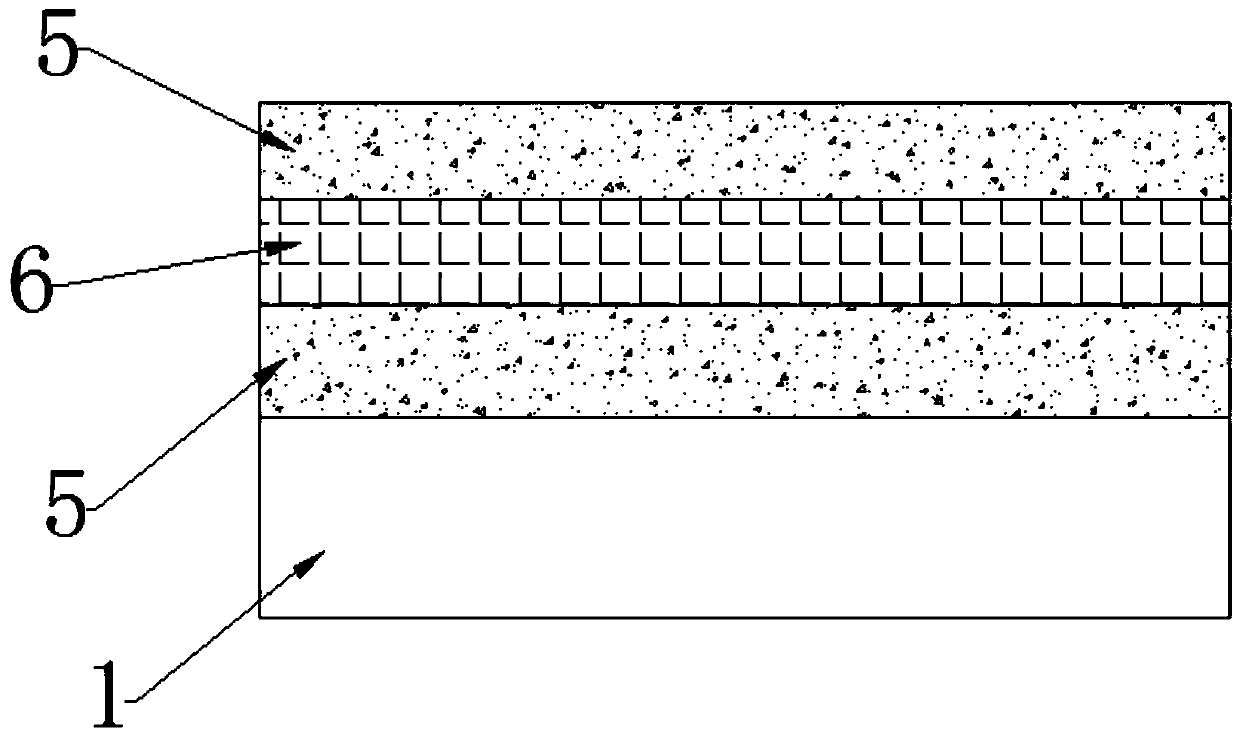

[0036] S3: Prepare the base-level safety interlining, plain weave the warp and weft yarns prepared in step S2, pull the cloth surface with a setting machine, and press it through a hot pressing roller, wherein the temperature of the hot pressing roller is controlled at 160-170 ℃, get the base safety interlining...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the mass ratio of the composite adhesive in the step S1 is that the composite adhesive layer includes 80 parts of hot melt adhesive, 10 parts of Teflon and 3 parts of nano-graphene oxide , the mass concentration of the moisture absorption and perspiration aid in the moisture absorption and perspiration aid solution in the step S3 is 3%, and the bath ratio is 1:0.8.

Embodiment 3

[0047] The difference between Example 3 and Example 1 is that the mass proportion of the composite adhesive in the step S1 is that the composite adhesive layer includes 75 parts of hot melt adhesive, 5 parts of Teflon and 5 parts of nano graphene oxide , the mass concentration of the moisture absorption and perspiration aid in the moisture absorption and perspiration aid solution in the step S3 is 4%, and the bath ratio is 1:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com