Preparation method of organosilicon surfactant used for preparing polyurethane rigid foam

A surfactant and rigid foam technology, applied in the chemical industry, can solve problems such as milky white, opaque, and poor compatibility of polyurethane composite materials, and achieve the effect of improving the skin and transparent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

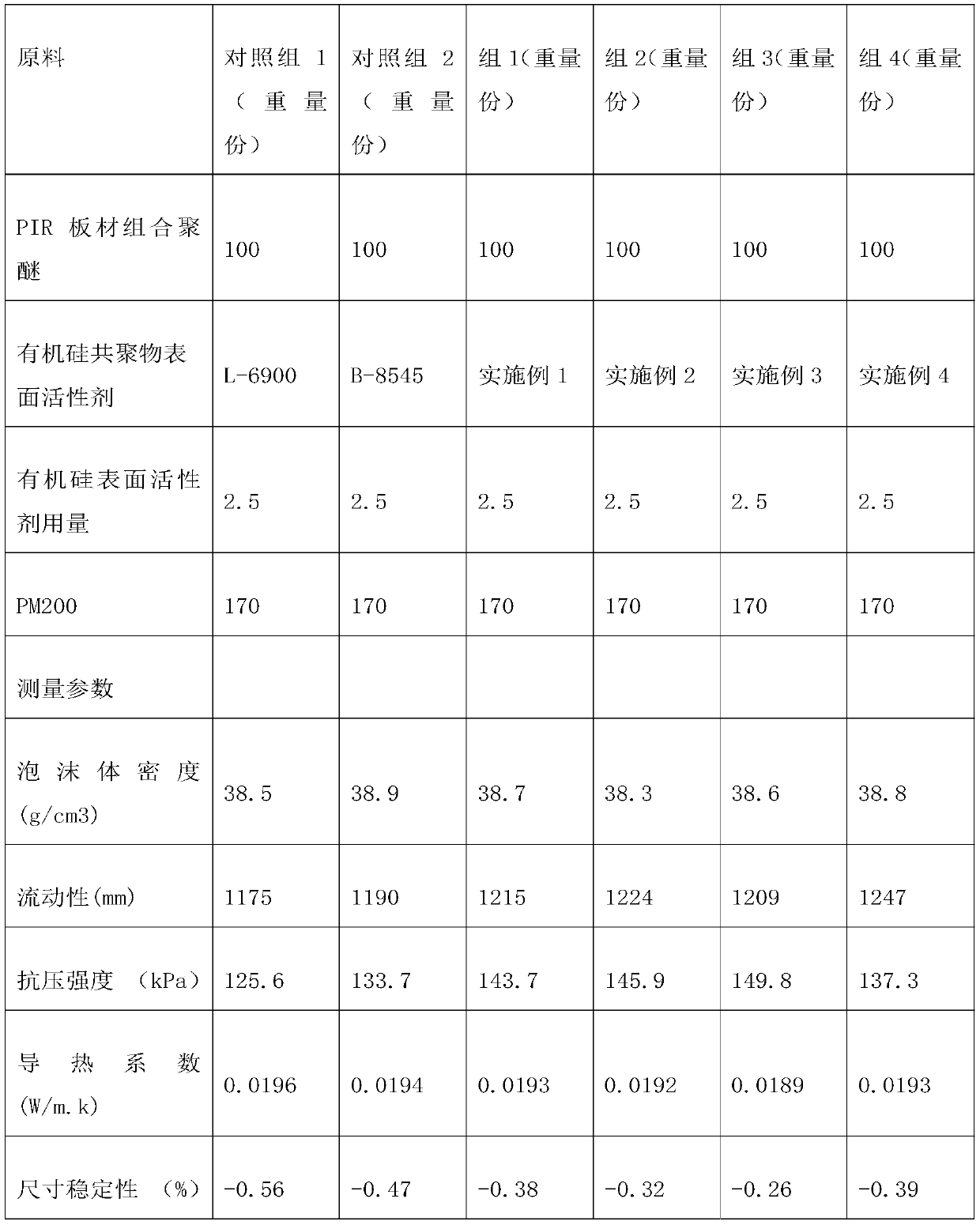

Examples

Embodiment 1

[0018] The preparation of embodiment 1 organosilicon copolymer surfactant

[0019] In a 500ml four-neck flask with a fixture, constant temperature function, mechanical stirring, thermocouple and nitrogen, add 350g of allyl chloride-terminated allyl polyoxyethylene with an average molecular weight of 2100 starting from butanol Ether, this polyoxyethylene ether contains the oxirane group that mol percent is 45% and the propylene oxide group that mol percent is 55%, then 150g low hydrogen-containing polysiloxane (hydrogen content is 0.15%) Add it into a four-neck flask, start stirring, heat to 80°C with a heating mantle, stir for 5 minutes, add chloroplatinic acid ethanol solution, after adding chloroplatinic acid ethanol solution, the concentration of chloroplatinic acid in the entire reaction system is 15ppm. After reacting for 3 hours, a clear and transparent light yellow liquid is obtained, which is the silicone copolymer surfactant. The hydroxyl value is 0 according to GB / T ...

Embodiment 2

[0020] The preparation of embodiment 2 organosilicon copolymer surfactants

[0021] In a 500ml four-neck flask with a fixed device, constant temperature function, mechanical stirring, thermocouple and nitrogen, add 350g of polyoxyethylene with an average molecular weight of 2200 and an allyl chloride terminated with ethylene glycol butyl ether. Ether, polyoxyethylene ether contains 45% oxirane groups by mole percent and 55% propylene oxide groups by mole percent, and then 150g of low hydrogen-containing polysiloxane (0.15% hydrogen content) is added In the four-neck flask, start stirring, use a heating mantle to heat to 80°C, stir for 5 minutes, add chloroplatinic acid ethanol solution, after adding chloroplatinic acid ethanol solution, make the concentration of chloroplatinic acid in the entire reaction system 15ppm. After reacting for 3 hours, a clear and transparent light yellow liquid is obtained, which is the silicone copolymer surfactant. The hydroxyl value is 0 accordin...

Embodiment 3

[0022] The preparation of embodiment 3 organosilicon copolymer surfactants

[0023] In a 500ml four-neck flask with a fixed device, constant temperature function, mechanical stirring, thermocouple and nitrogen gas, add 350g of polyoxyethylene with an average molecular weight of 2300 and an allyl chloride terminated with ethylene glycol propyl ether. Ether, polyoxyethylene ether contains 45% oxirane groups by mole percent and 55% propylene oxide groups by mole percent, and then 150g of low hydrogen-containing polysiloxane (0.15% hydrogen content) is added In the four-neck flask, start stirring, use a heating mantle to heat to 80°C, stir for 5 minutes, add chloroplatinic acid ethanol solution, after adding chloroplatinic acid ethanol solution, make the concentration of chloroplatinic acid in the entire reaction system 15ppm. After reacting for 3 hours, a clear and transparent light yellow liquid was obtained, which was the organosilicon copolymer surfactant with a hydroxyl value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com