Fine art work full-automatic carving system and method thereof

A fully-automated, work-oriented technology, applied in the field of art, can solve the problems of low degree of mechanization and automation, low work and operation efficiency, and inaccurate control, etc., to achieve precise engraving precision control, high work and operation efficiency, and beautiful finished products high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

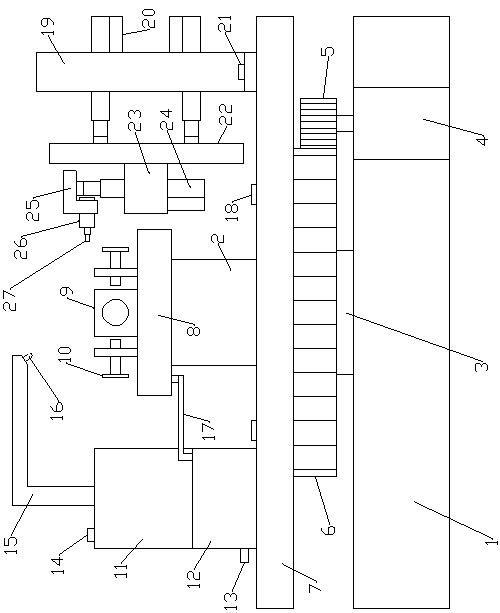

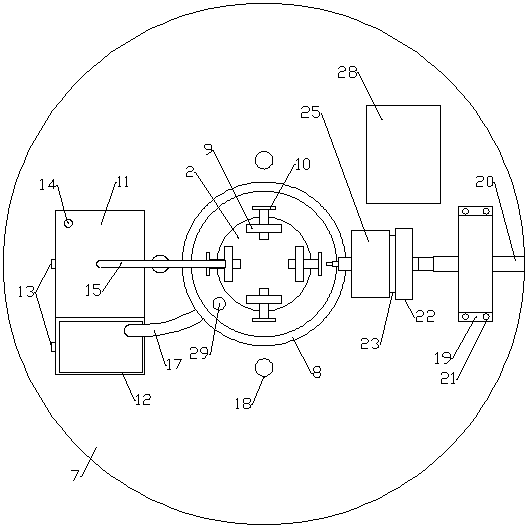

[0022] Embodiment 1: an engraving method of the above-mentioned full-automatic engraving system for works of art, the engraving method is as follows: first, the article to be engraved is clamped by the screw adjusting clamping rod 10 provided on the longitudinal clamping block 9, and the article to be engraved The bottom of the bottom is clamped between the longitudinal clamping blocks 9 by modifying or adding a connecting piece, and then the engraving path of the rotary engraving head 27 is designed by the control computer, and after the engraving path of the rotary engraving head 27 is designed according to the control computer software , by controlling the computer to send an engraving command to the controller 28, after the controller 28 receives the engraving command, it transmits the signal to the first electric push rod 20, the second electric push rod 24, the active motor 4 and the engraving motor 26 to be connected. The motor 4 drives the driving gear 5 to run accordin...

Embodiment 2

[0023] Embodiment 2: a kind of engraving method of the above-mentioned full-automatic engraving system for works of art, its engraving method is as follows: first, the article to be engraved is clamped by the screw adjusting clamping rod 10 provided on the longitudinal clamping block 9, and the article to be engraved The bottom of the bottom is clamped between the longitudinal clamping blocks 9 by modifying or adding a connecting piece, and then the engraving path of the rotary engraving head 27 is designed by the control computer, and after the engraving path of the rotary engraving head 27 is designed according to the control computer software , send engraving commands to the controller 28 through the control computer, after the controller 28 receives the engraving commands, it transmits the signals to the water pump, the first electric push rod 20, the second electric push rod 24, the active motor 4 and the engraving motor 26 phases. Connected, the active motor 4 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com