Plastic granulation equipment

A kind of granulation equipment and plastic technology, applied in the direction of coating, etc., can solve the problems of uneven shape, uneven size, consumption, etc., and achieve the effect of high appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

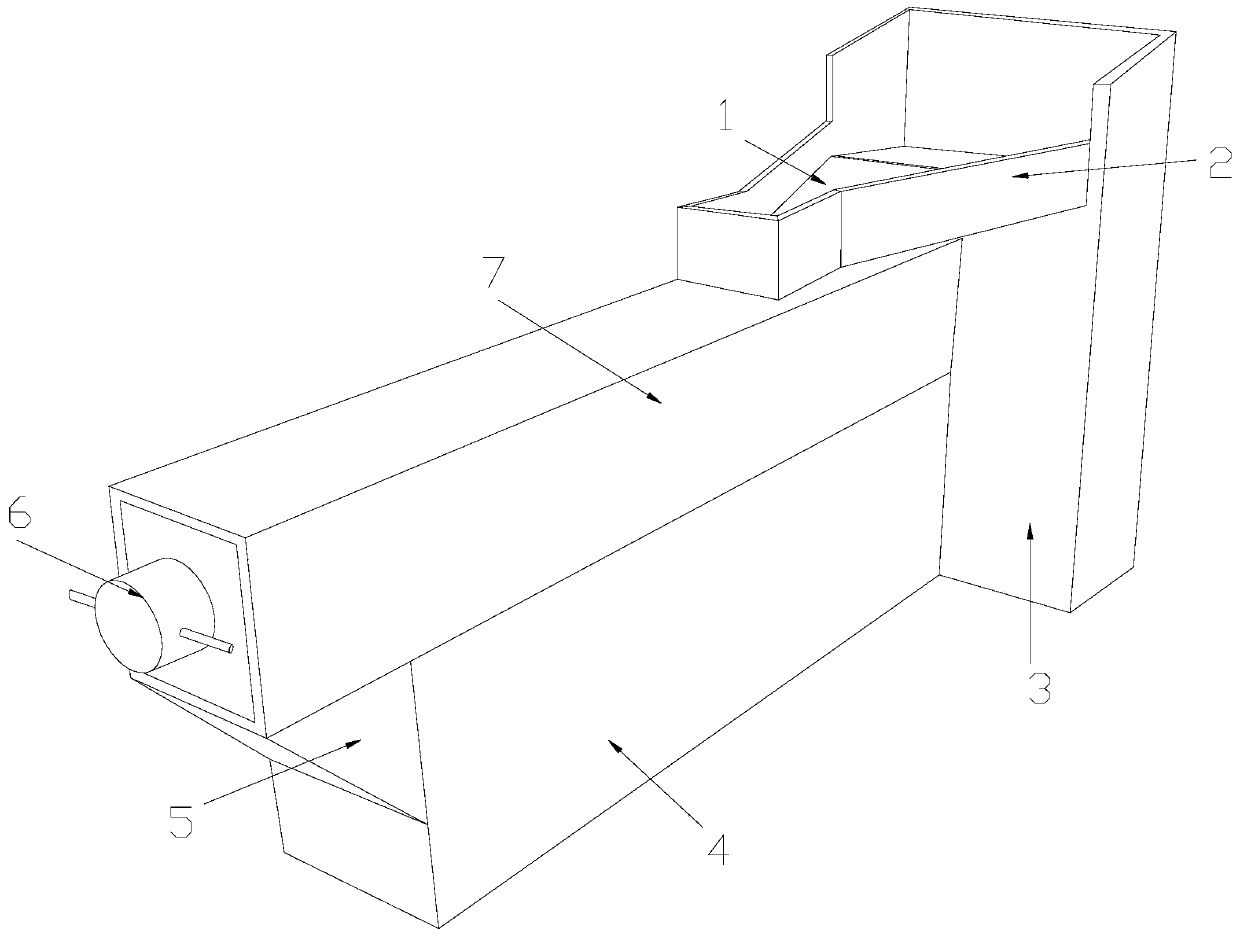

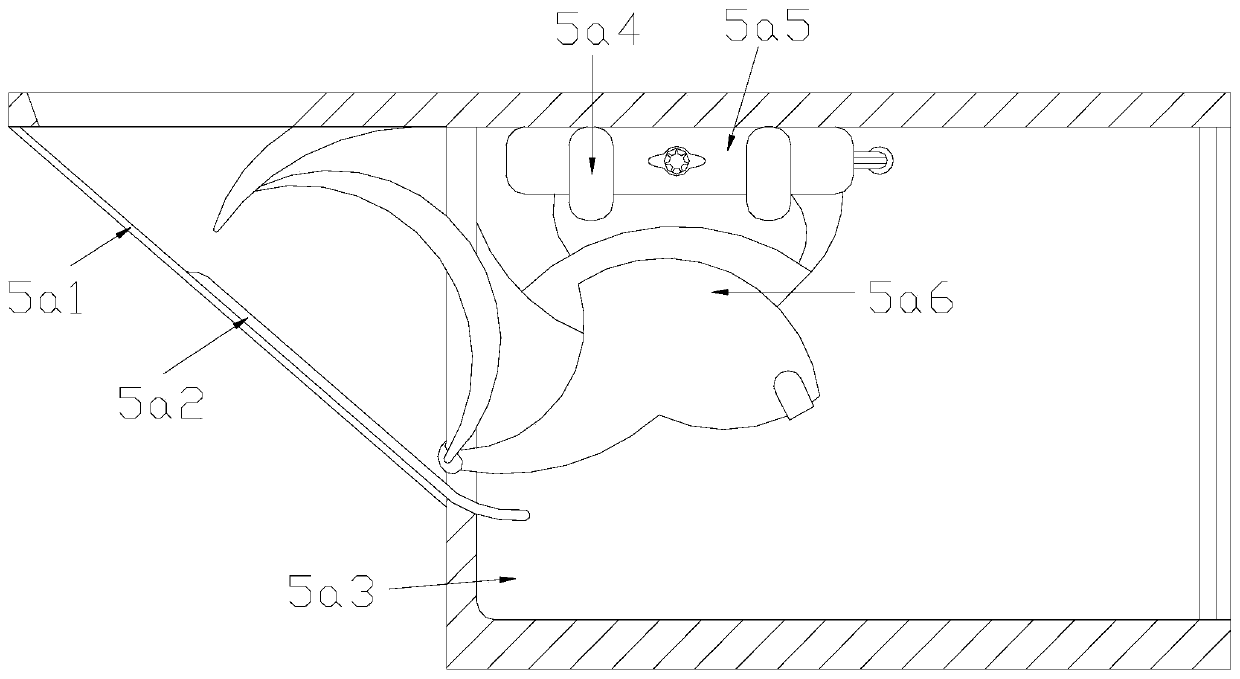

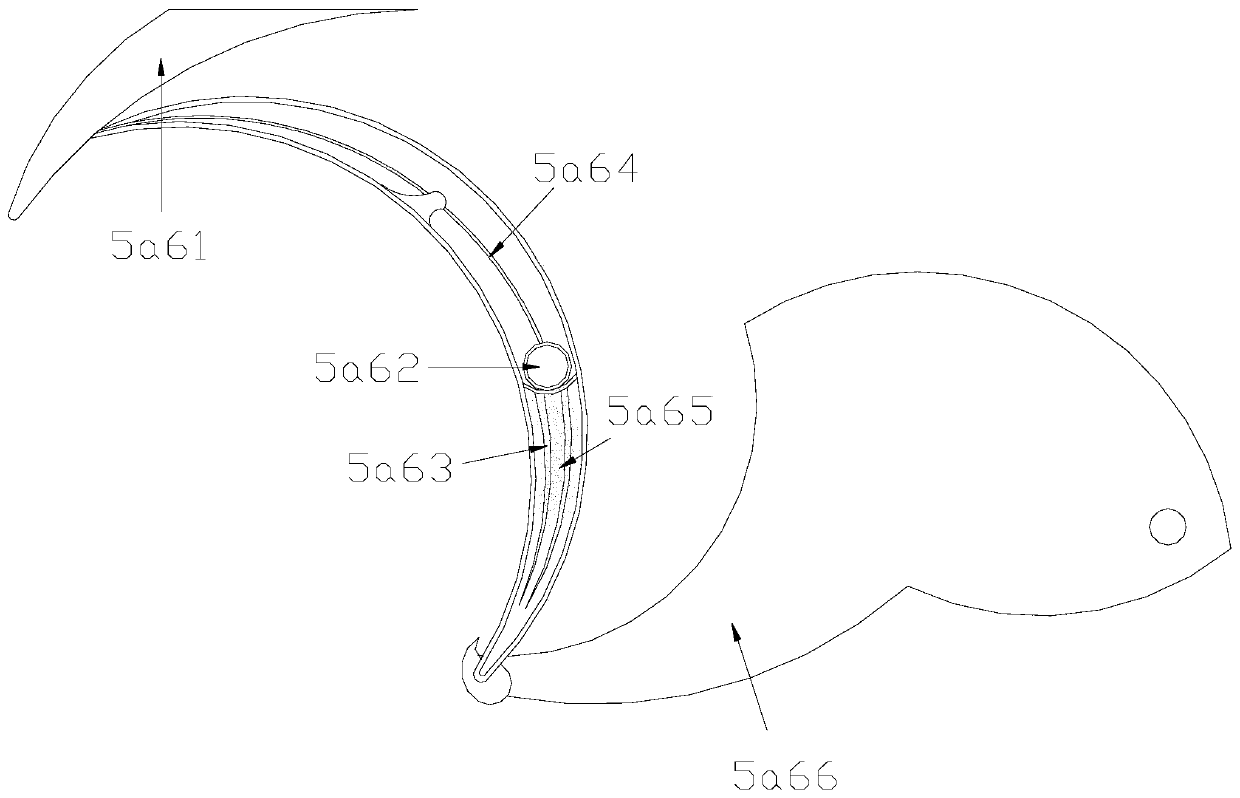

[0027] as attached figure 1 to attach Figure 7 Shown:

[0028] The invention provides a plastic granulation equipment, the structure of which includes a warping guide 1, a material holding frame 2, a material control console 3, a material support box 4, a material leveling cycle internal cleaning device 5, a maintenance seal 6, a melting material The pelletizing cylinder 7, the warping guide piece 1 is arranged inside the material holding frame 2, the right end of the material holding frame 2 is fixedly connected to the top of the scrap control console 3 by means of electric welding, and the material holding support box 4 is fixedly installed with The bottom end of the melting and granulating cylinder 7, the right end of the homogenizing circulation internal cleaning device 5 is fixedly connected to the left end of the material support box 4 by electric welding, and the maintenance seal 6 is arranged at the left end of the melting and granulating cylinder 7. The internal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com