High-efficiency core cleaning machine

An oil washing machine and core technology, applied in the field of high-efficiency core oil washing machines, can solve the problems of poor oil washing effect, slow speed, low efficiency, etc., and achieve the effects of rapid cleaning, efficient oil washing, and ensuring condensation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

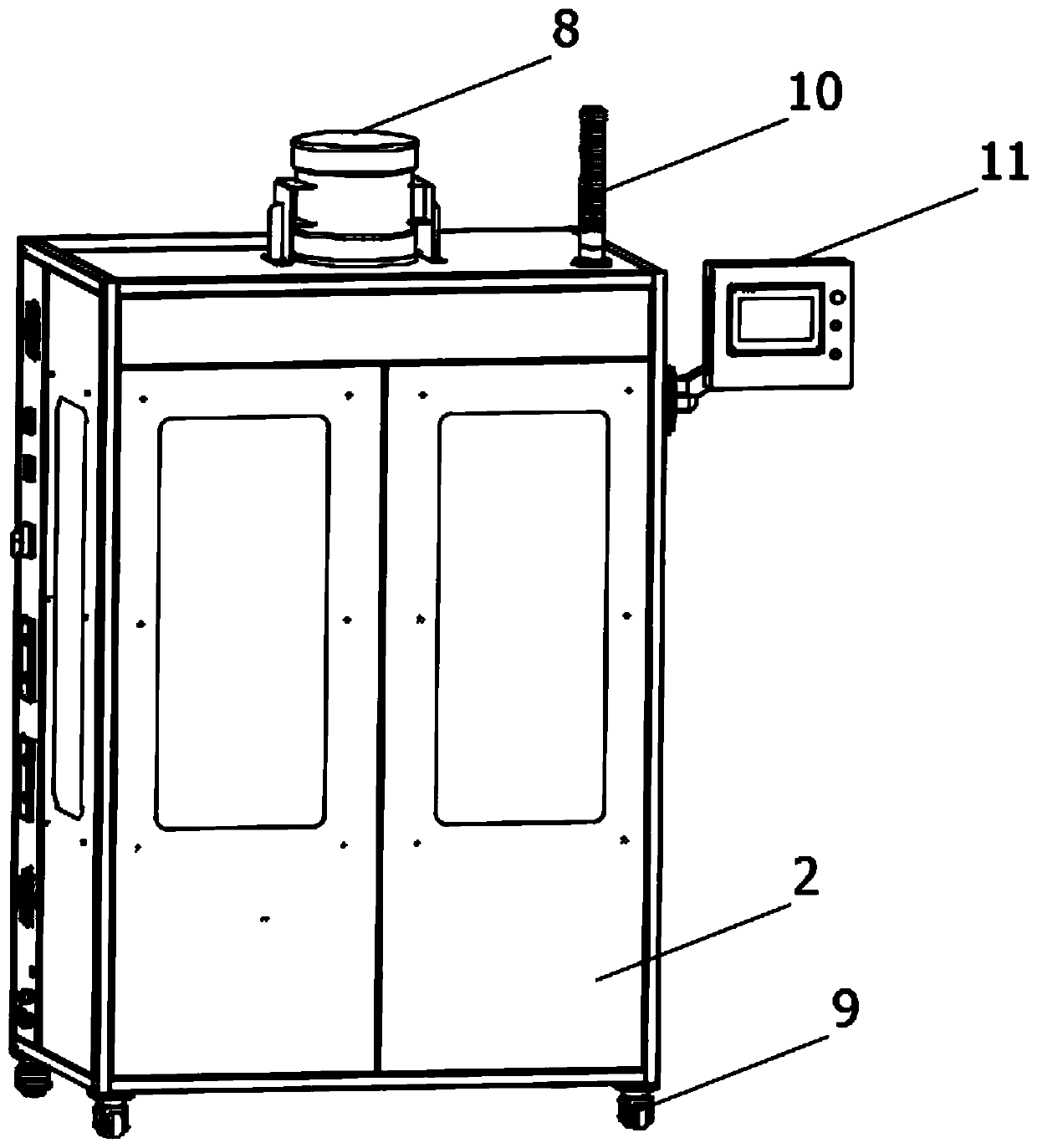

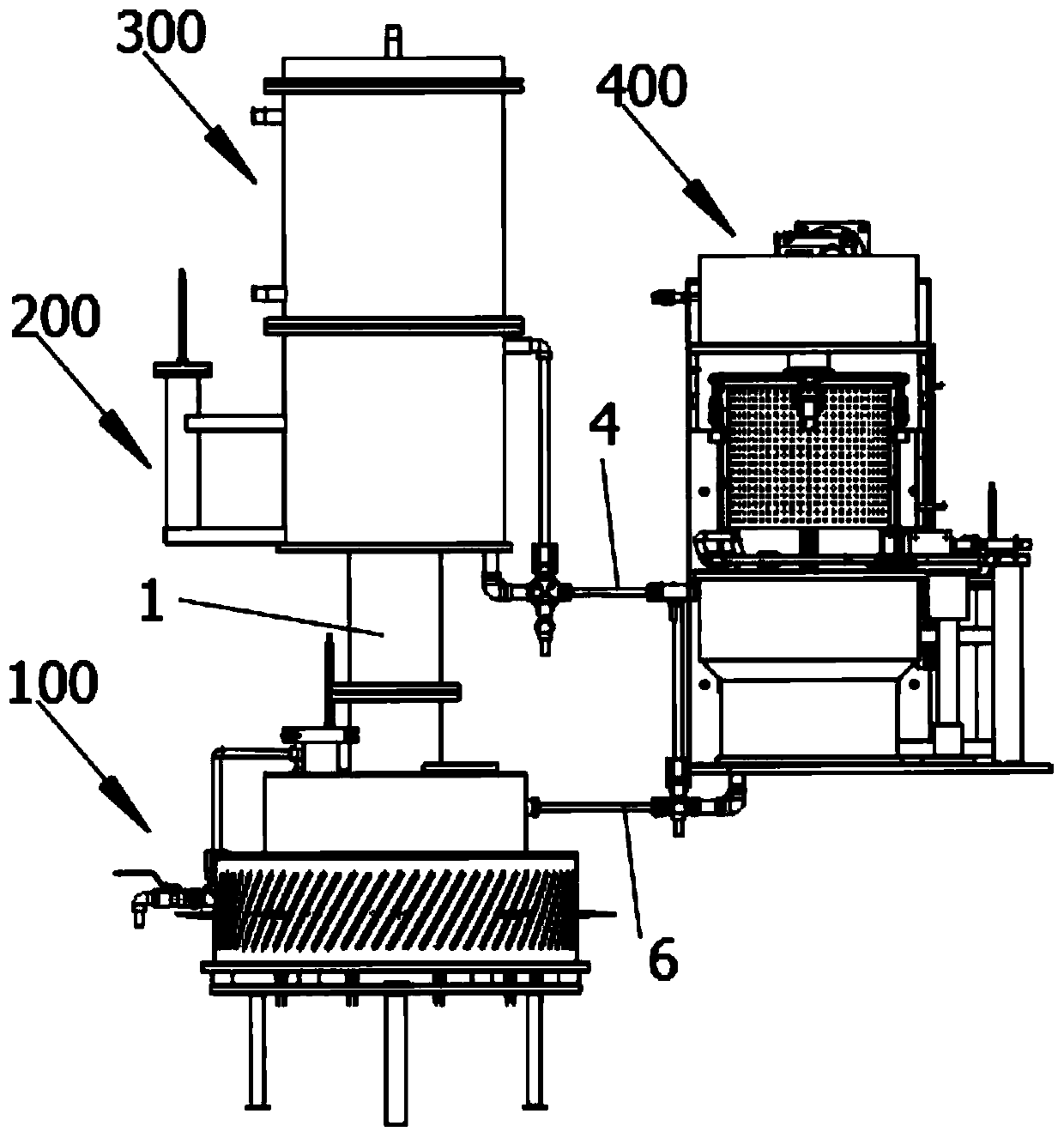

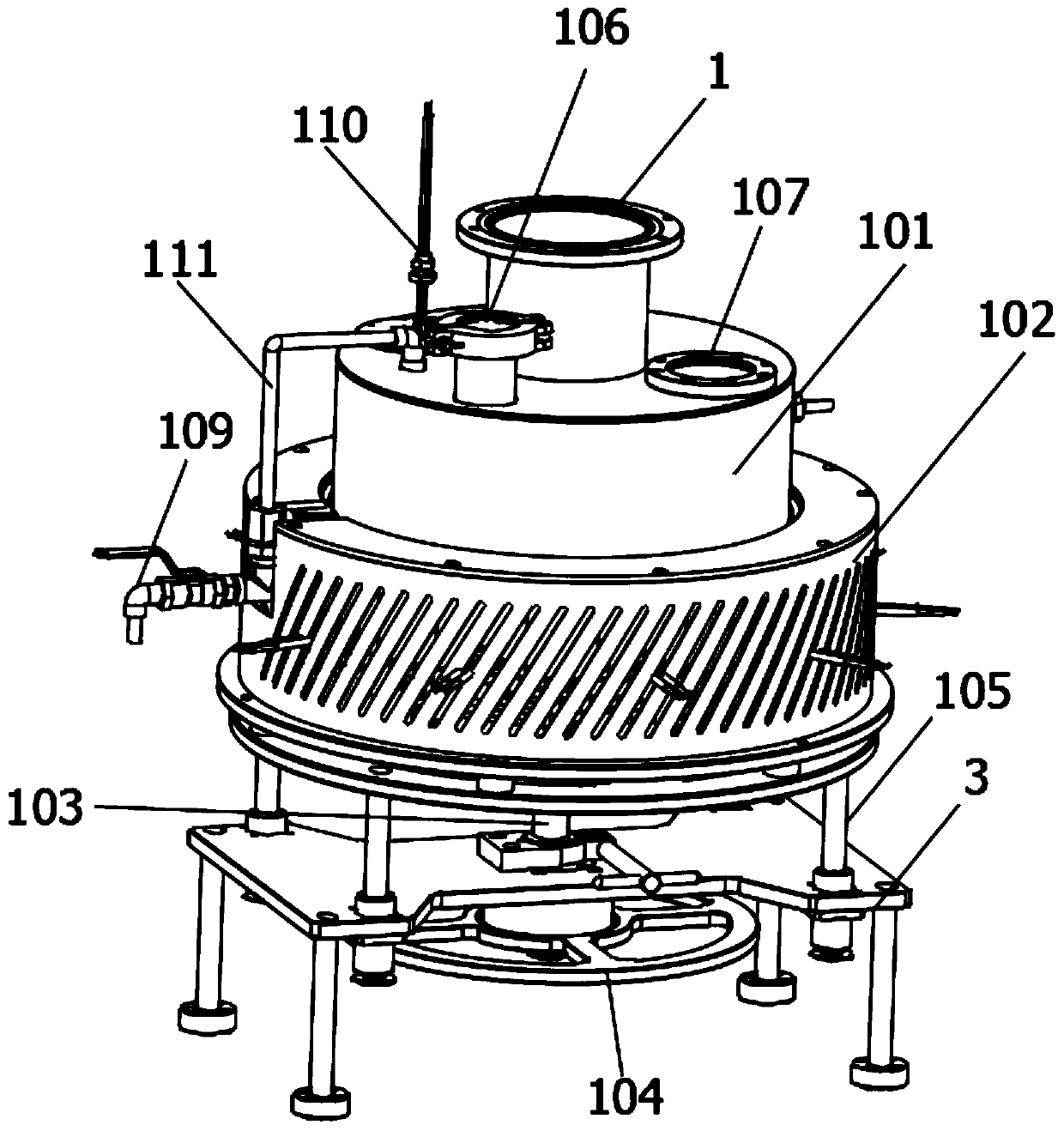

[0051] Embodiment: a kind of high-efficiency rock core oil washing machine, such as Figure 1-Figure 15 As shown, it includes an evaporating part 100, a liquid collecting part 200, a condensing part 300 and an oil washing part 400. The evaporating part communicates with the liquid collecting part, the liquid collecting part communicates with the condensing part, and the liquid collecting part The lower end of the component communicates with the oil washing component, and the lower end of the oil washing component communicates with the evaporation component;

[0052] The evaporation component includes an oil storage chamber 101 and a heating module 102 for heating the oil storage chamber;

[0053] The liquid collecting part includes a liquid collecting chamber 201, and the liquid collecting chamber communicates with the oil storage chamber through the steam pipe 1;

[0054] The condensing part includes a condensing chamber 301, and the liquid collection chamber communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com