Foaming flowback agent for oil field fracturing and application thereof

A foaming flowback, oil field fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of wax, colloid, asphaltene, etc. in fracturing fluid filter cake and formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

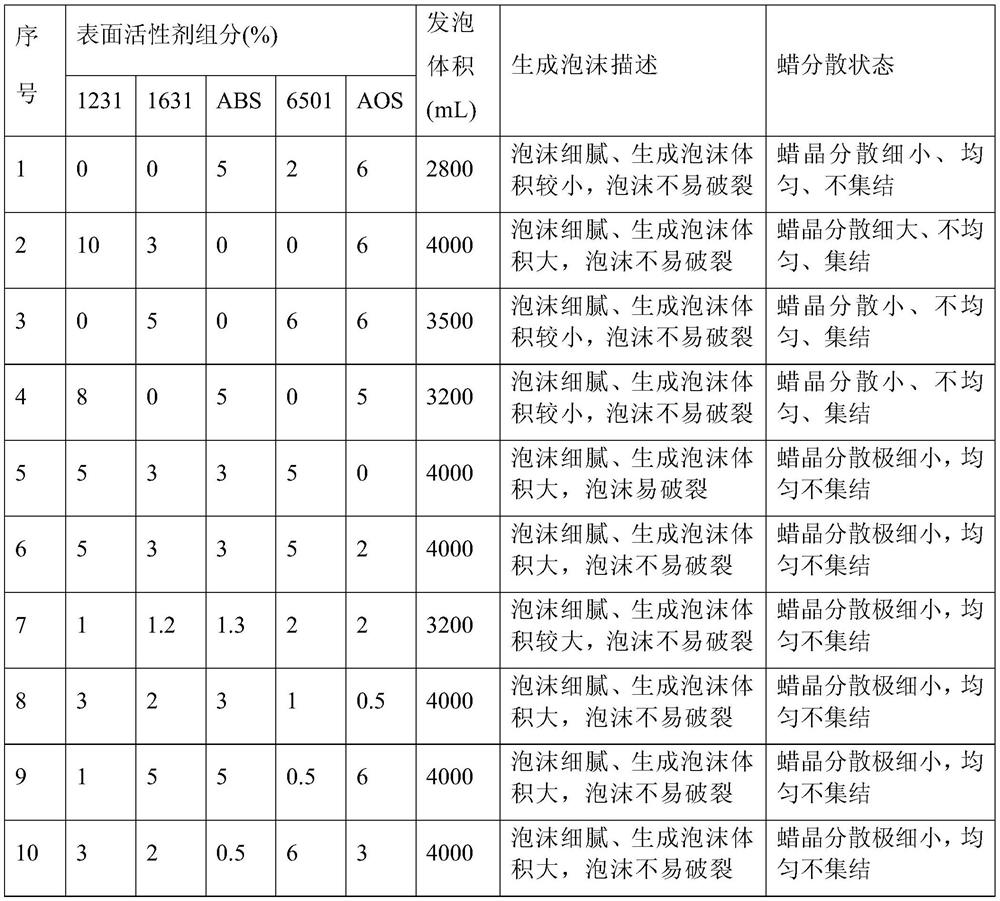

Examples

Embodiment 1

[0048] Preparation of agent A: first put 65% of water into the reaction kettle, add 30% sodium nitrite to make it completely dissolved, then add 5% of fast penetrating agent T, stir well to make agent A;

[0049] Preparation of agent B: first put 71.5% of water into the reaction kettle, add 18% of ammonium chloride to dissolve it completely, then add 3% of ammonium persulfate, then add 1% of 1231 surfactant, 1.2% of the 1631 surfactant, 1.3% of the ABS surfactant, 2% of the AOS surfactant and 2% of the coconut oil diethanolamide 6501 were stirred evenly to make agent B.

[0050] At room temperature, after mixing 100mL of Agent A and Agent B, put 1g of 57# white wax ball into it, the highest reaction temperature can reach 95℃, and the maximum bubble volume can reach 3200mL. After stirring, the wax presents fine particles and is evenly dispersed.

Embodiment 2

[0052] Preparation of Agent A: First, put 64.5% of water into the reaction kettle, add 35% of sodium nitrite to dissolve it completely, then add 0.5% of fast penetrating agent T, stir well to make Agent A;

[0053] Preparation of agent B: first put 65.5% of water into the reaction kettle, add 25% of ammonium chloride to dissolve it completely, then add 3% of 1231 surfactant, 2% of 1631 surfactant, 3 % of ABS surfactant, 1% of AOS surfactant and 0.5% of coconut oil diethanolamide 6501, stirred evenly to make agent B.

[0054] At 65°C, after mixing 100mL of Agent A and Agent B, put 1g of 57# white wax ball, the highest reaction temperature can reach 103°C, and the maximum bubble volume can reach more than 4000mL. After stirring, the wax presents fine particles and is evenly dispersed.

Embodiment 3

[0056]Preparation of agent A: first put 66% of water into the reaction kettle, add 32% of sodium nitrite to make it completely dissolved, then add 2% of fast penetrating agent T, stir well to make agent A;

[0057] Preparation of agent B: first put 54.9% of water into the reaction kettle, add 22% of ammonium chloride to dissolve it completely, then add 0.6% of ammonium persulfate, then add 10% of 1231 surfactant, 1% of 1631 surfactant, 2.5% of ABS surfactant, 6% of AOS surfactant and 3% of coconut oil diethanolamide 6501 were stirred evenly to make Agent B.

[0058] At room temperature, after mixing 100mL of Agent A and Agent B, put 1g of 57# white wax balls into it, the highest reaction temperature can reach 93°C, and the maximum bubble volume can reach 3800mL. After stirring, the wax presents fine particles and is evenly dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com