High-precision glass cutting tool bit device

A glass cutting and high-precision technology, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low precision and poor compatibility of panel specifications, and achieve high precision, strong product compatibility and market competition The effect of a wide range of force and pressure output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

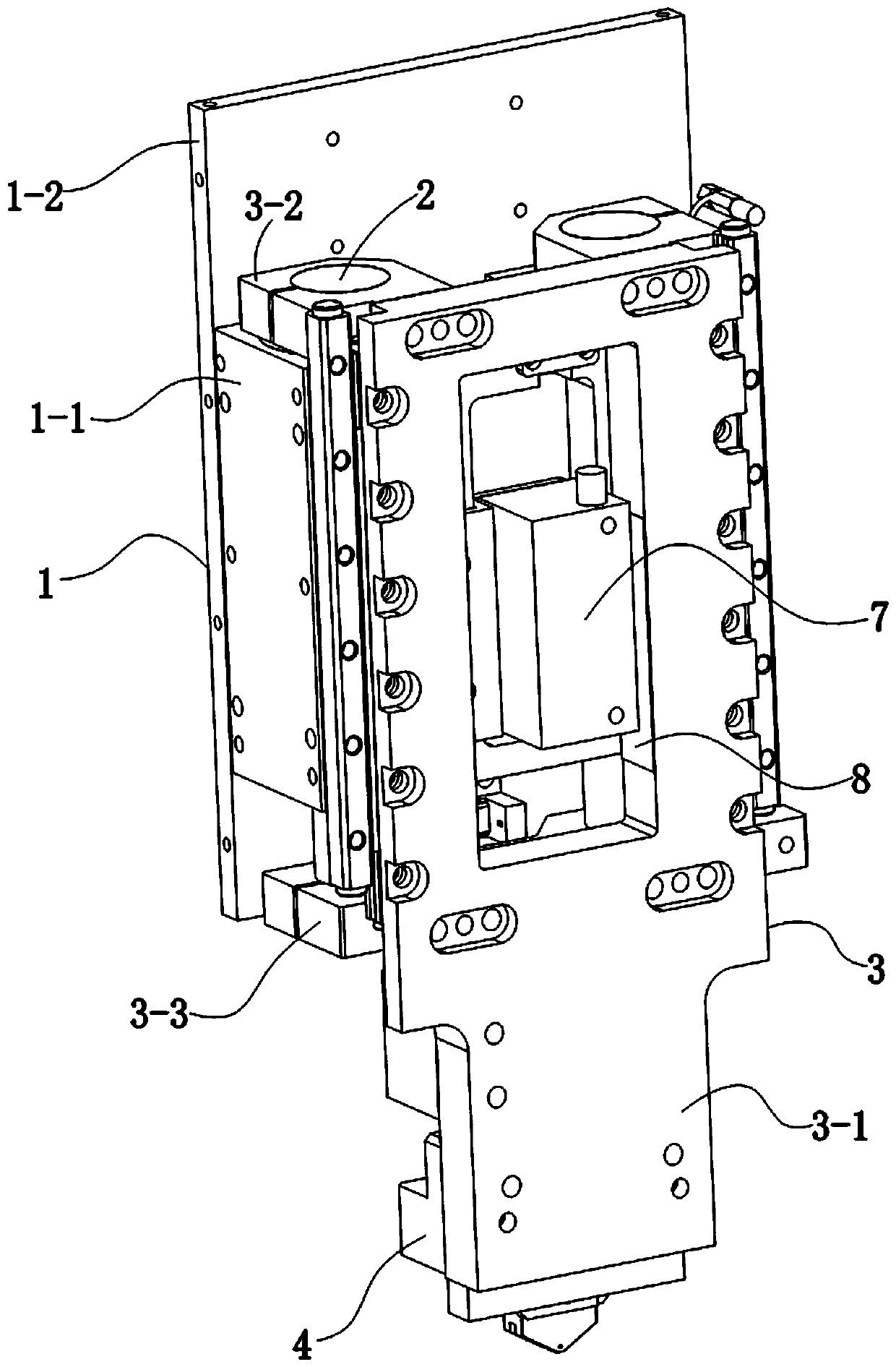

[0017] refer to Figure 1 to Figure 5 , a high-precision glass cutting head device of the present invention includes a fixed frame 1, a linear motor 2, a sliding frame 3, and a cutter wheel mechanism 4, and the stator 2-1 of the linear motor 2 is fixedly connected to the fixed frame 1 , the mover 2-2 of the linear motor 2 is fixedly connected to the sliding frame 3, the fixed frame 1 and the sliding frame 3 are slidingly connected through the guide rail pair 5, and the fixed frame 1 and the sliding frame 3 are also connected Connected by extension spring 6, the axis of the linear motor 2, the guide rail pair 5, and the extension spring 6 are parallel to each other, and the cutter wheel mechanism 4 is fixed on the sliding frame 3, and the cutter wheel mechanism 4 can be used for linear cutting The linear cutting knife wheel mechanism 4 can also be a special-shaped cutting knife wheel mechanism 4 for special-shaped cutting. The specific type is selected according to customer nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com