Automatic welding equipment for pipeline

An automatic welding and pipeline technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult welding, difficult to control weld quality, time-consuming and labor-intensive, etc., to improve welding efficiency and welding quality Stable and easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and usage methods of the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

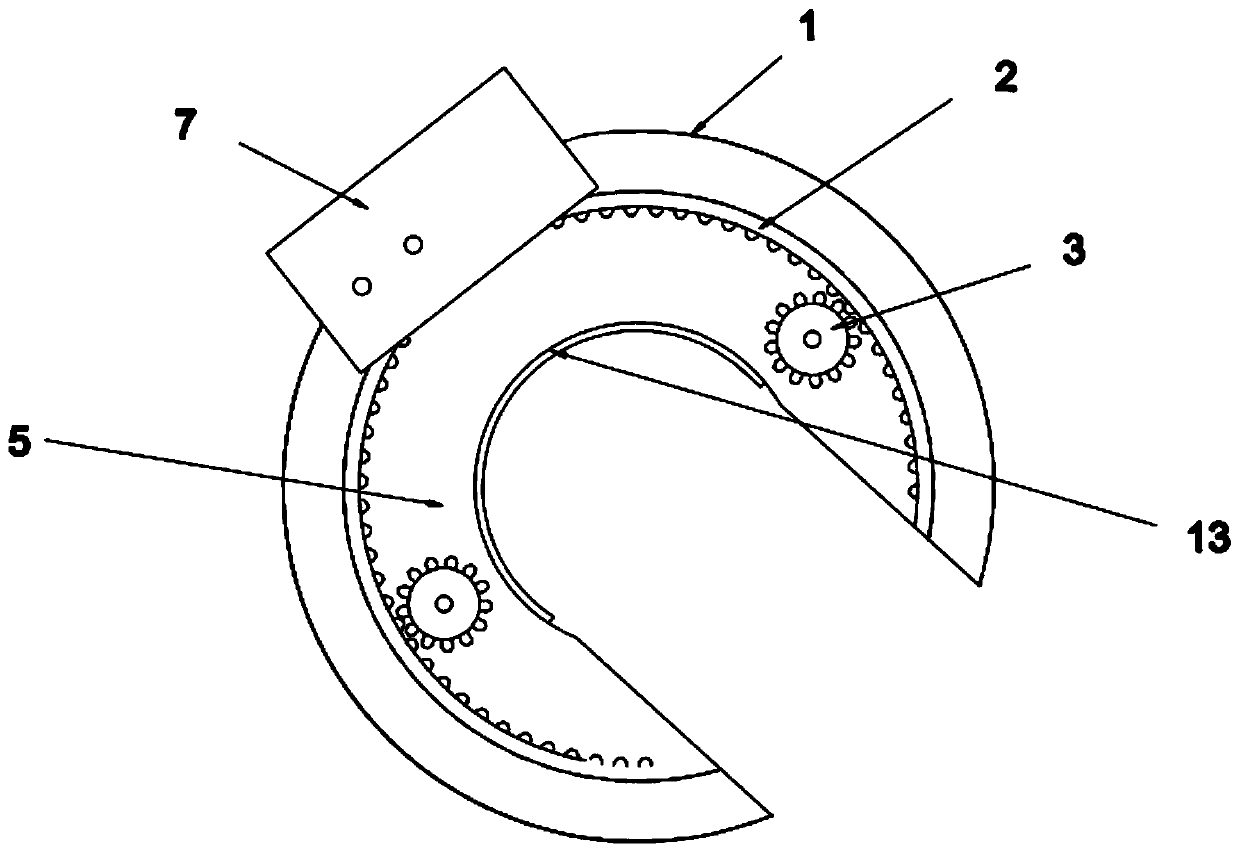

[0023] combined with figure 1 To attach Figure 7 , a pipeline automatic welding equipment, including a casing 1, the outer wall of the casing 1 is provided with a control box 10, the inner side of the casing 1 is coaxially provided with a pipeline liner 6, and the top inner wall of the casing 1 is connected to the pipeline liner 6, a rack bearing platform 5 is arranged, and the side of the rack bearing platform 5 away from the pipeline liner 6 is provided with a rack slideway corresponding to the radian of the edge of the rack bearing platform. The arc-shaped ring gear 2 movably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com