Oil-coal mixing process as well as designing method and application thereof

A mixing process, oil-coal technology, applied in mixing methods, petroleum industry, chemical instruments and methods, etc., can solve the problems of uneven mixing of oil-coal slurry two-phase, difficult transportation and measurement, and easy agglomeration of coal powder. The effect of short time, few programs, and even three-phase mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

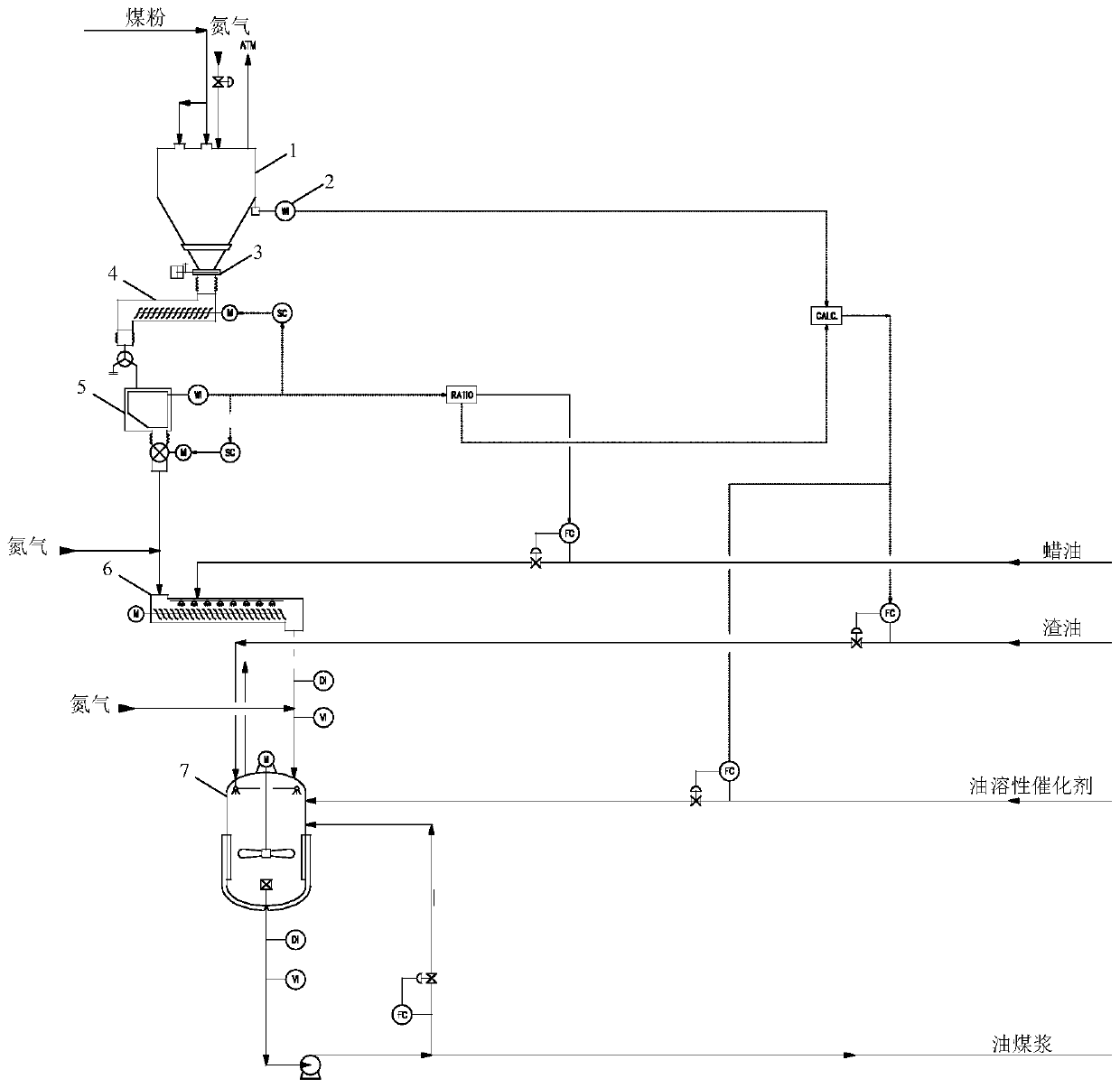

[0034] For further elaborating specific features of the present invention, will combine figure 1 and specific examples are described.

[0035] An oil-coal mixing process, comprising the following processes:

[0036] The pulverized coal from the coal preparation device enters the pulverized coal bin 1, and the residence time in the pulverized coal bin 1 is 2 hours, where the temperature is 80°C, the pressure is a micro positive pressure of ≤80KPa, the normal material level is 60%, and the pulverized coal The particle size is 60-90μm. A measuring instrument 2, a remote oxygen concentration detector and a humidity detector are installed on the pulverized coal bin 1. During the buffering period, the emergency shut-off valve 3 is closed, and the weight of pulverized coal, oxygen concentration and temperature are measured, and the data is transmitted to the computer remotely. The shaft length of the conveyor 4 is 3.5 meters, and the vibration transmission prevents coal dust from ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap