Paint roller with automatic feeding function

An automatic feeding and coating technology, which is applied in the direction of construction and building construction, can solve the problems of coating agglomeration, labor difficulty, heavy weight, etc., and achieve the effects of preventing coating agglomeration, reducing workload and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

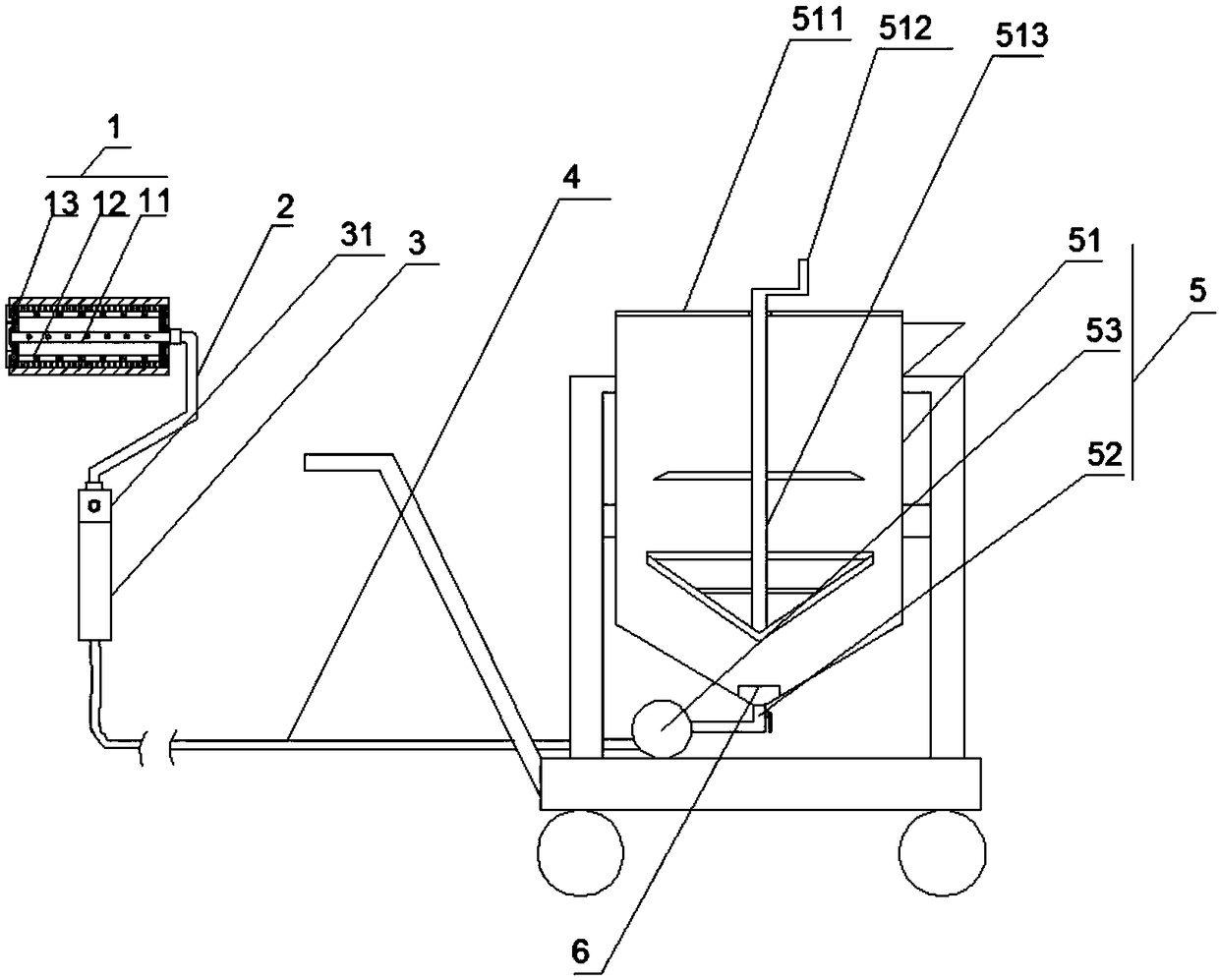

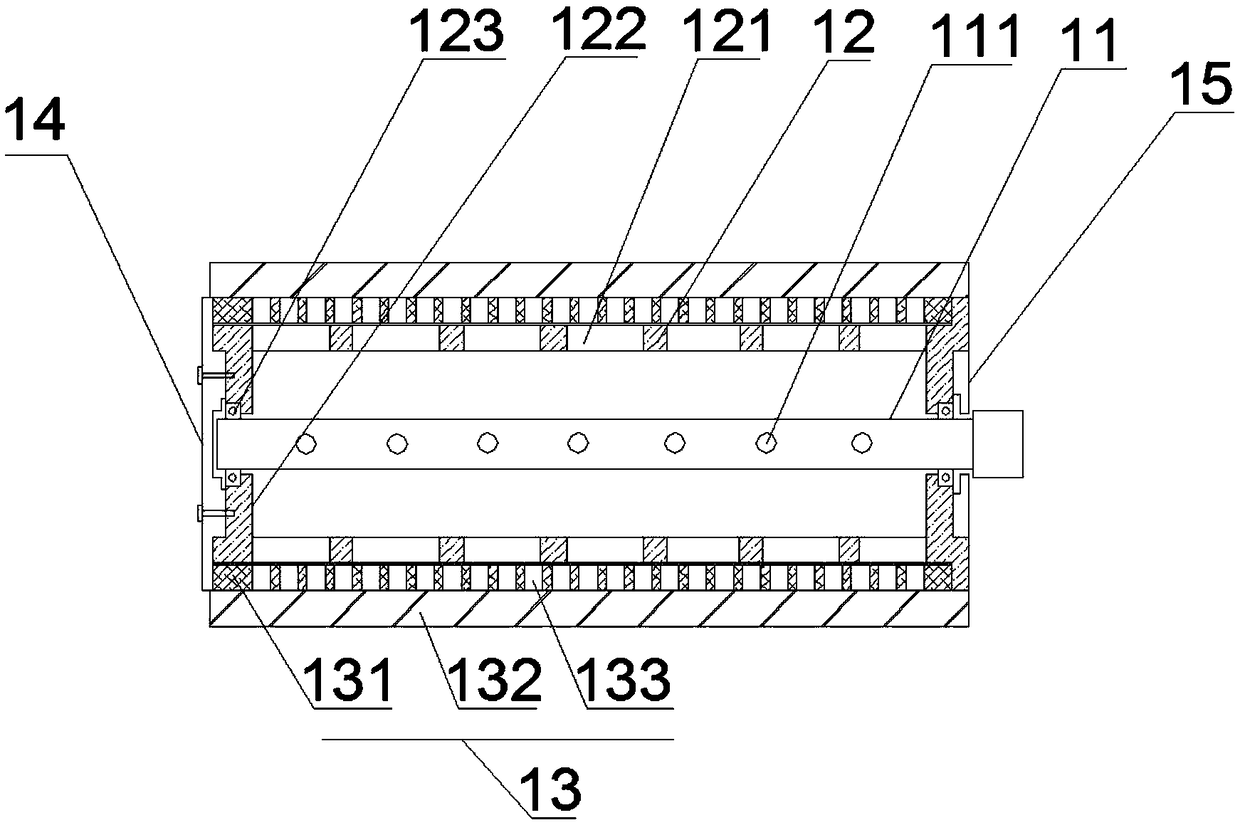

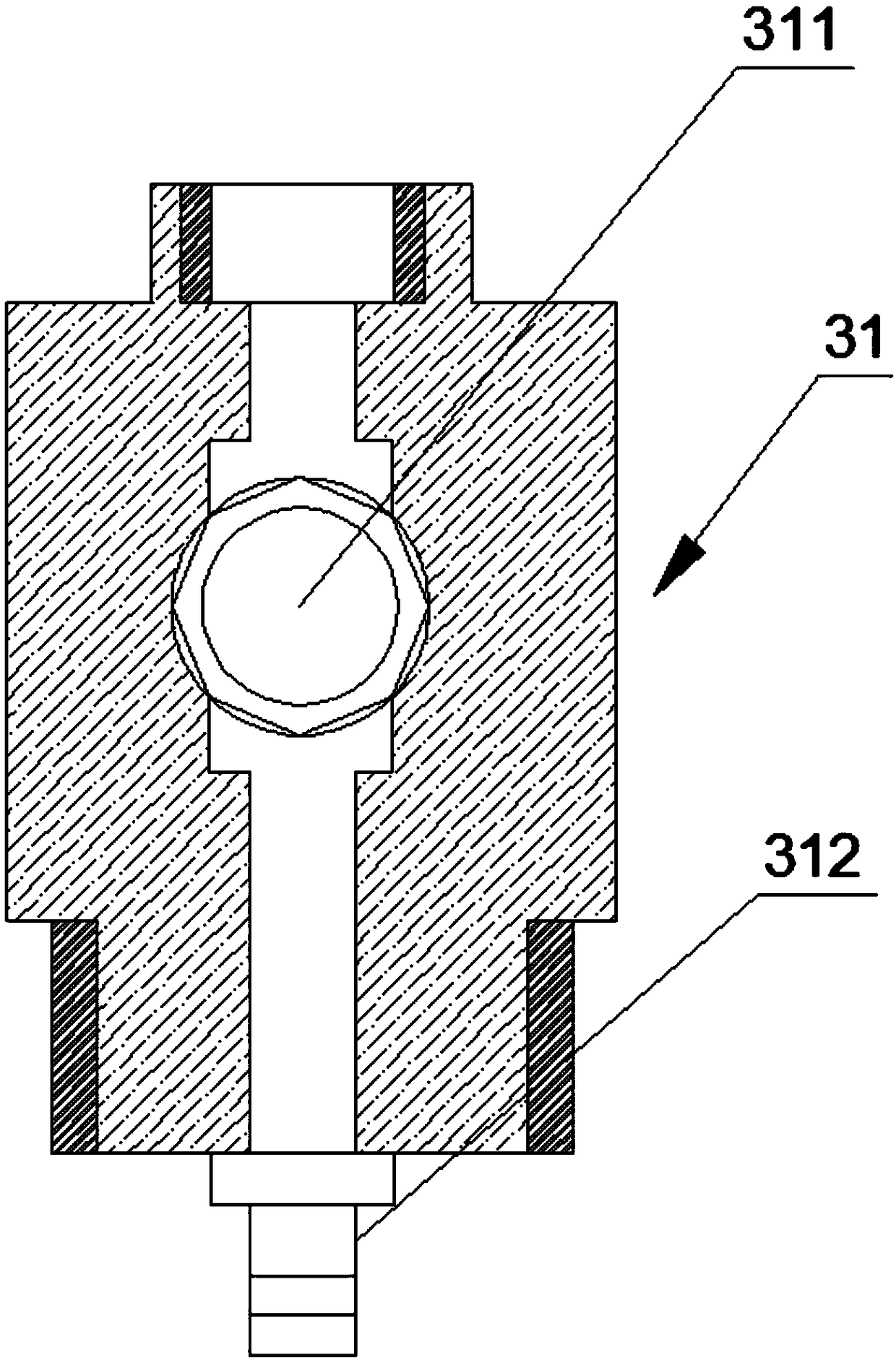

[0040] refer to Figure 1-4 , a paint roller for automatic feeding, including a roller brush 1, a connecting pipe 2, a telescopic rod 3, a feeding pipe 4 and a feeding device 5, and the roller brush 1 includes a shaft tube 11, an installation cylinder 12, a bristle cylinder 13, and a left end cover 14 And the right end cover 15, the left end of the shaft tube 11 is sealed, the installation tube 12 is rotatably installed on the outside of the shaft tube 11, the bristle tube 13 is detachably fixed on the outside of the installation tube 12, and the left end cover 14 is screwed At the left end of the installation cylinder 12, the right end cover 15 is embedded in the right end of the installation cylin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap