Novel and efficient dust collecting equipment for glass grinding

A dust-collecting equipment and high-efficiency technology, used in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of incomplete dust separation and purification, difficulty in moving and fixing equipment, affecting processing work, etc. Achieve the effect of improving purification and separation effect, reducing noise pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

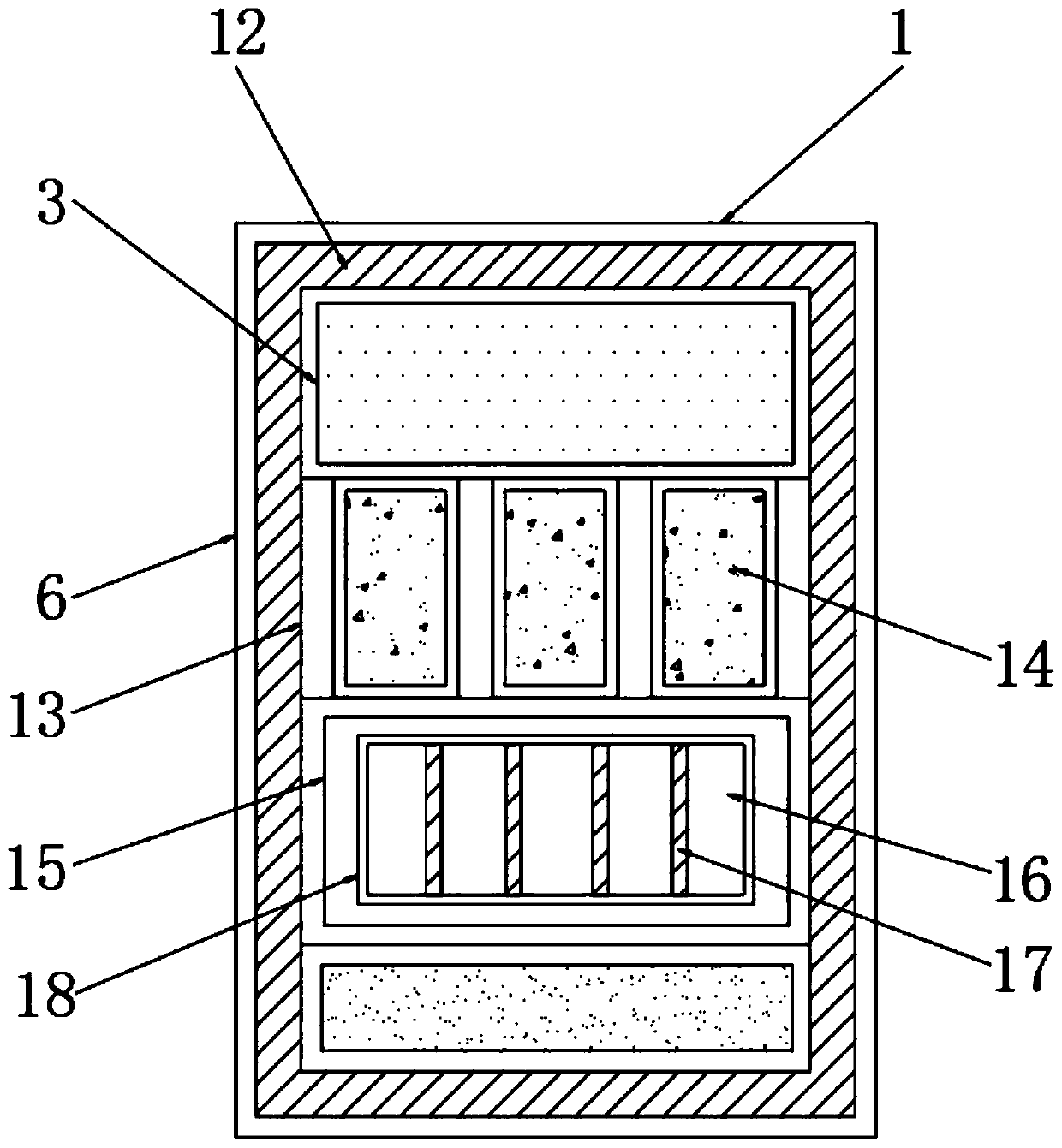

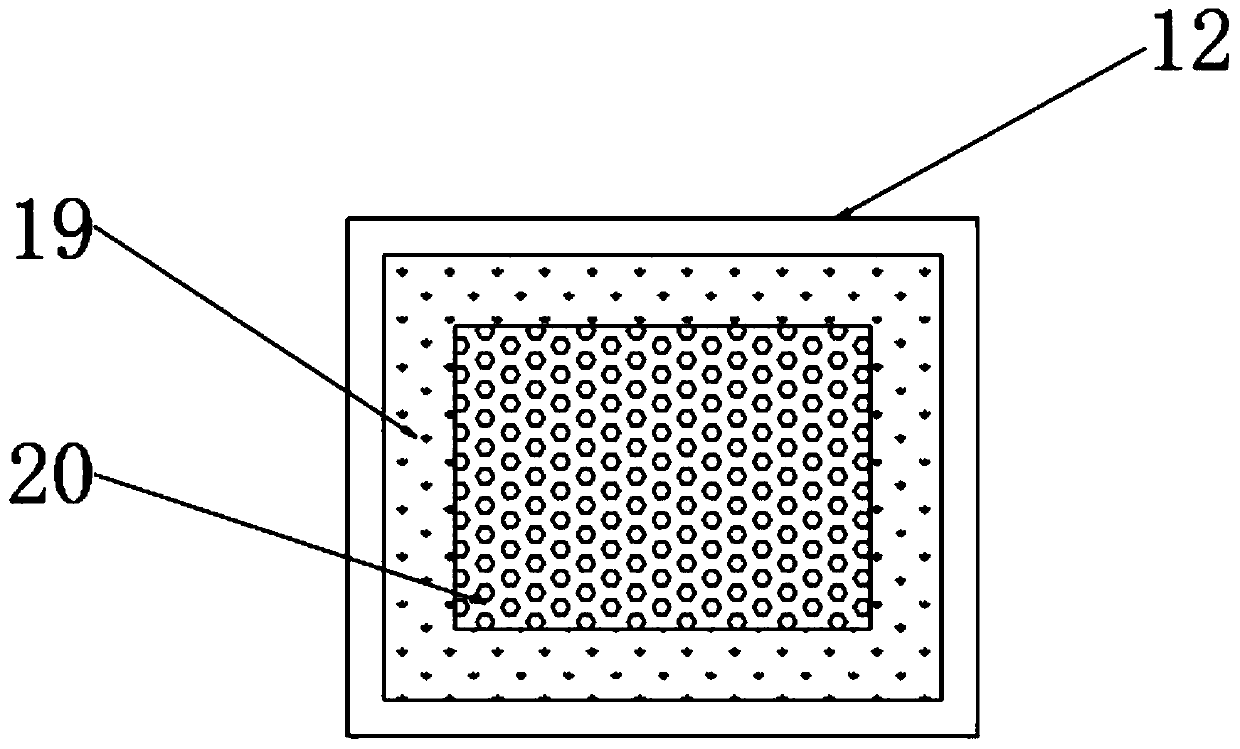

[0021] see Figure 1~3 , in an embodiment of the present invention, a new type of high-efficiency dust collection equipment for glass grinding, including a dust collector body 1, an air inlet 2, a fan box 3, a control panel 4, a temperature sensor 5, a dust cleaning box 6, and a dust discharge box 7. Pulley 8, support plate 9, screw rod 10, drag rod 11, micro-perforated sound-absorbing panel 12, filter layer 13, filter barrel 14, electrostatic precipitator layer 15, dust collecting pole 16, corona pole 17, dust collecting plate 18 , fire-proof and sound-absorbing cloth 19 and density board 20, the top of the dust collector body 1 is provided with an air inlet 2, and the bottom end of the dust collector body 1 is equipped with a pulley 8, and one side of the dust collector body 1 is equipped with a tow bar 11, and the inner wall of the dust collector body 1 is equipped with a micro-perforated sound-absorbing panel 12, the fan box 3 is installed under the air inlet 2, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com