Flat plate evaporation equipment

A technology of evaporation equipment and flat plate, applied in the field of flat plate evaporation equipment, can solve the problems of increased maintenance cost, uncontrollable material film thickness, difficulty in maintaining the vacuum degree of the equipment, etc. The effect of film time shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

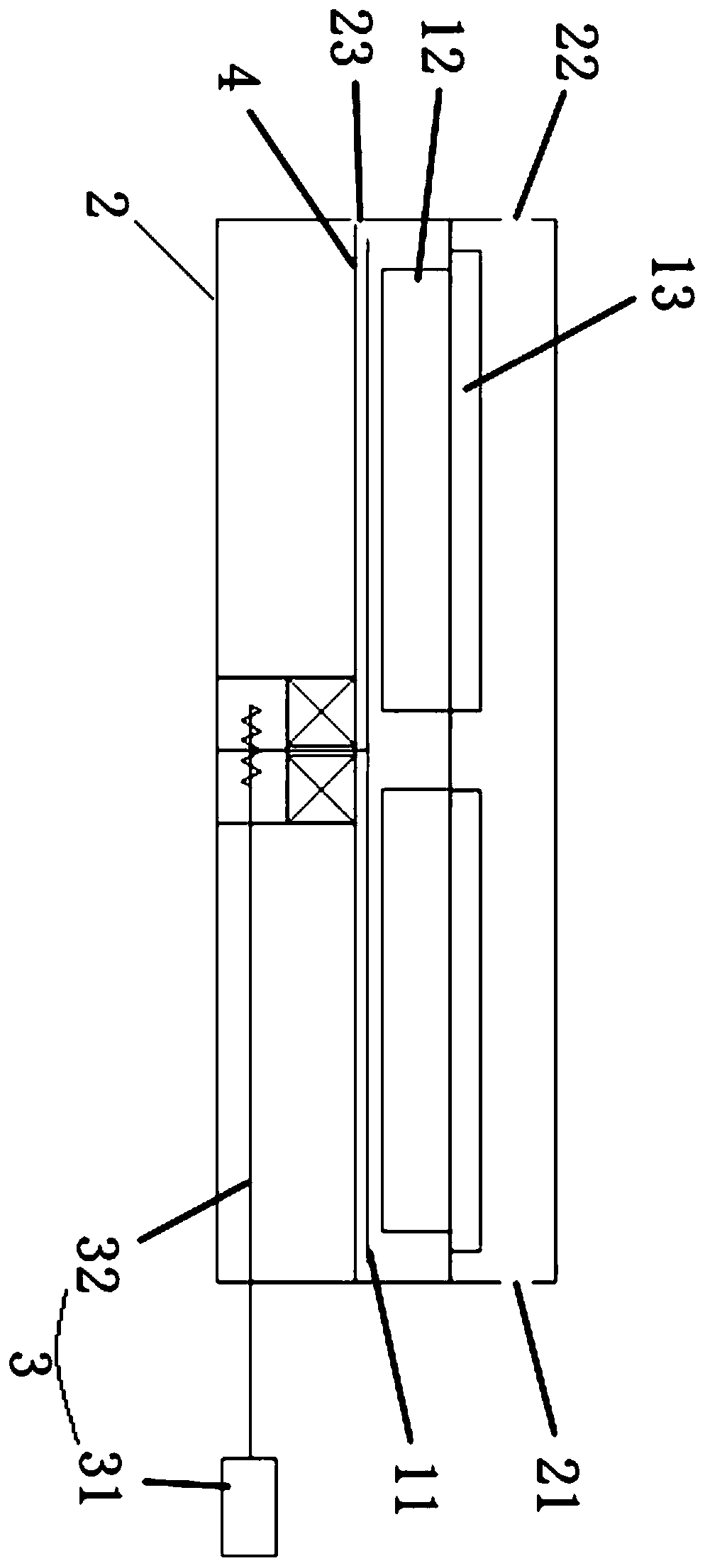

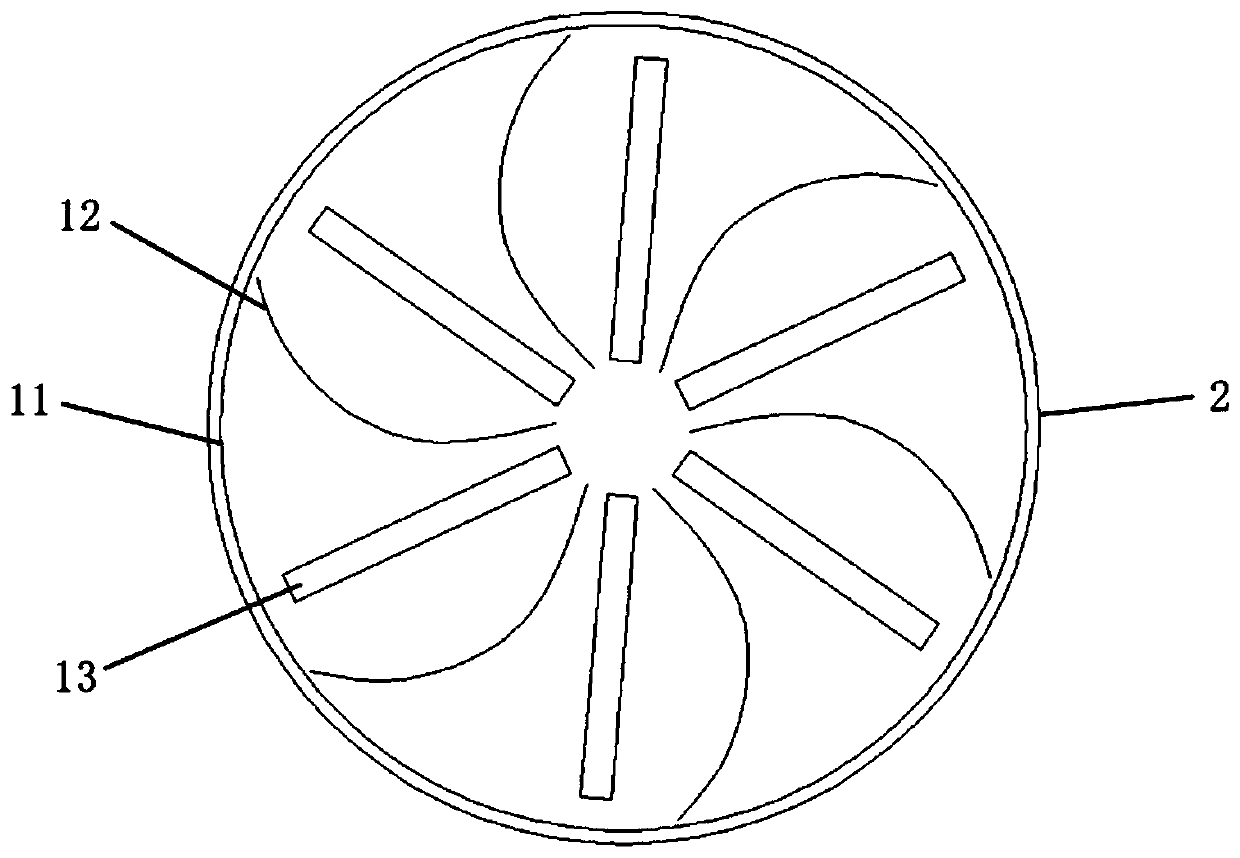

[0037] Such as figure 1 and figure 2 As shown, a flat plate evaporator 1 is installed in the cavity 2. The flat plate evaporator 1 includes a turntable 11 capable of rotating, a number of scrapers 12 located above the turntable 11 and capable of heating the surface of the turntable 11. The energy assembly 13; there is a gap between the bottom of the scraper 12 and the surface of the turntable 11. During the use of the present invention, firstly, the material enters the turntable 11 from the material inlet 21 on the surface of the cavity 2 through a conduit, and the turntable 11 is in the drive assembly. 3 under the action of high-speed rotation, due to the existence of the scraper 12, there is a gap between the scraper 12 and the turntable 11, so when the material is subjected to the centrifugal force on the turntable 11, it will quickly spread to the outer ring of the turntable 11, during the diffusion process Contact with the scraper 12, so that the material forms a thin f...

Embodiment 2

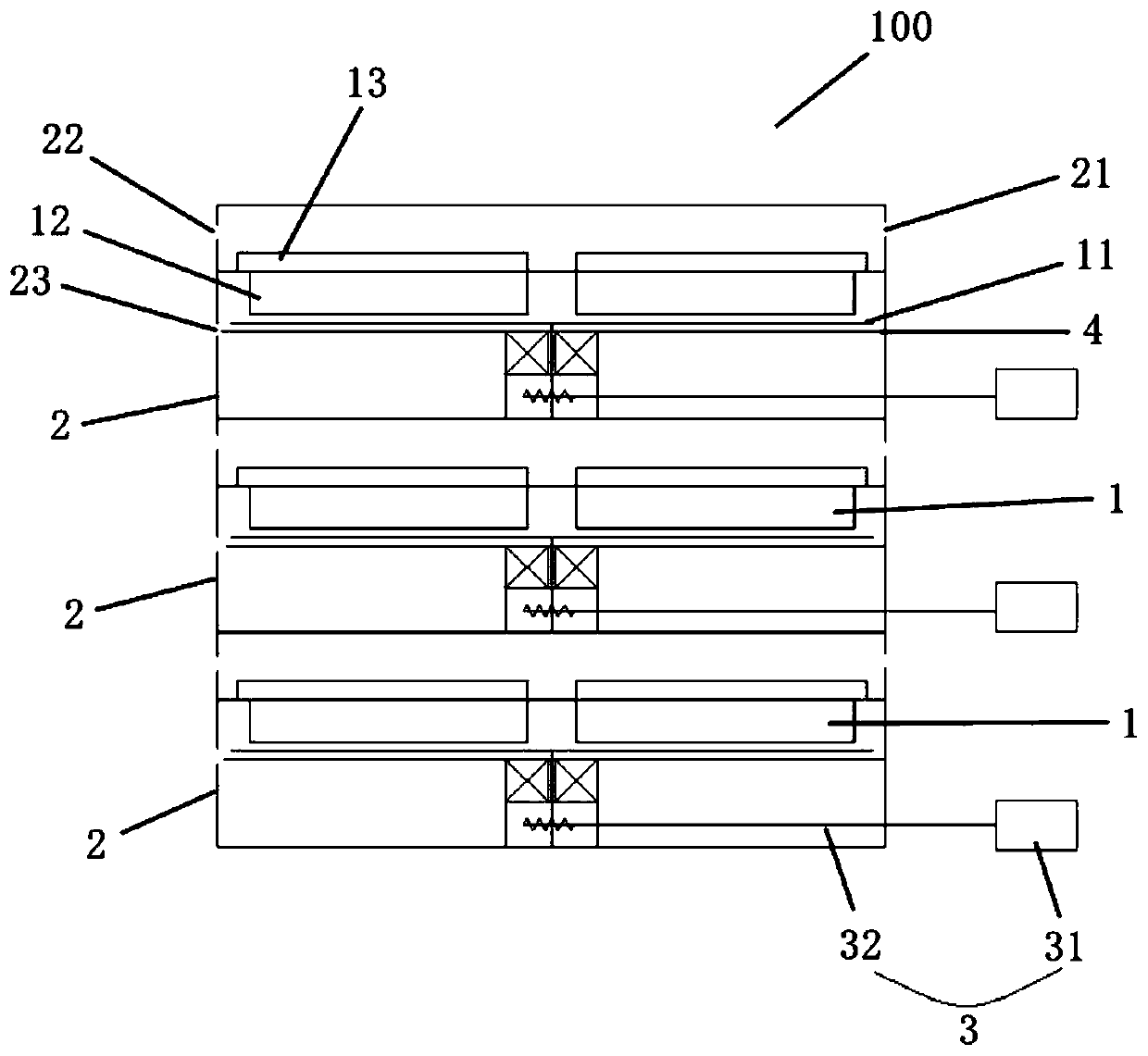

[0047] Such as image 3 As shown, a flat plate evaporating device 100 includes: (1) a plurality of cavities formed by stacking; (2) a flat plate evaporator installed in each cavity.

[0048] A plurality of cavities 2 are vertically stacked and parallel-connected. The surface of each cavity 2 is provided with a material inlet 21, a light item outlet 22, and a heavy item outlet 23. Each material inlet 21, light item outlet 22, and heavy item outlet are One group corresponds to a flat plate evaporator 1, and materials can enter the surface of the turntable 11 of the corresponding flat plate evaporator 1 from multiple material inlets 21 at the same time to perform material evaporation operations. The work of each flat plate evaporator 1 does not affect each other. The vertical stacking of multiple chambers 2 can separate multiple flat plate evaporators 1 to form multiple independent evaporation areas, thereby greatly improving the evaporation efficiency, increasing the evaporation...

Embodiment 3

[0050] Such as Figure 4 As shown, a flat plate evaporating device 100 includes: (1) a plurality of cavities formed by stacking; (2) a flat plate evaporator installed in each cavity.

[0051]A plurality of cavities 2 are vertically stacked and arranged in series. On the side of the top cavity 2, there are only one material inlet 21, one light item outlet 22 and one heavy item outlet 23. When the material enters the uppermost After the flat plate evaporator 1, the material evaporation operation of the first step is carried out. After the first step of evaporation operation is completed, the material received on the receiving tray 4 of the previous flat plate evaporator 1 enters the turntable 11 of the next flat plate evaporator 1, Carry out the material evaporation operation of the second step, and proceed to the next step in sequence until the material evaporates completely.

[0052] In this embodiment, the material receiving trays 4 are all inclined, so the material on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com