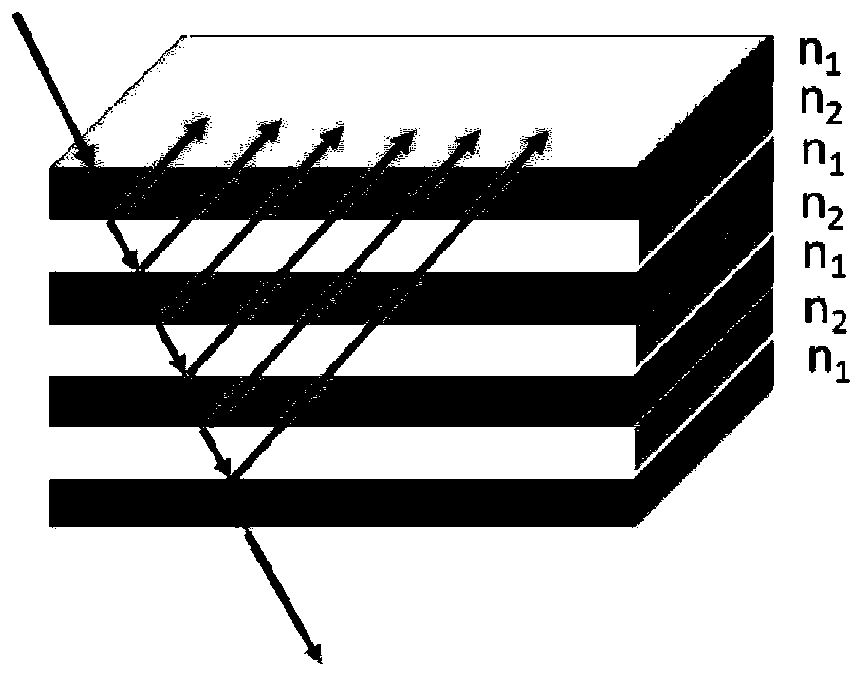

Optical structure based on cholesteric liquid crystal polymer semi-interpenetrating network and manufacturing method

A technology of cholesteric liquid crystal and semi-interpenetrating network, which is applied in the field of optical structure and preparation based on semi-interpenetrating network of cholesteric liquid crystal polymer, can solve the problem that the height can only reach 50%, and achieve good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

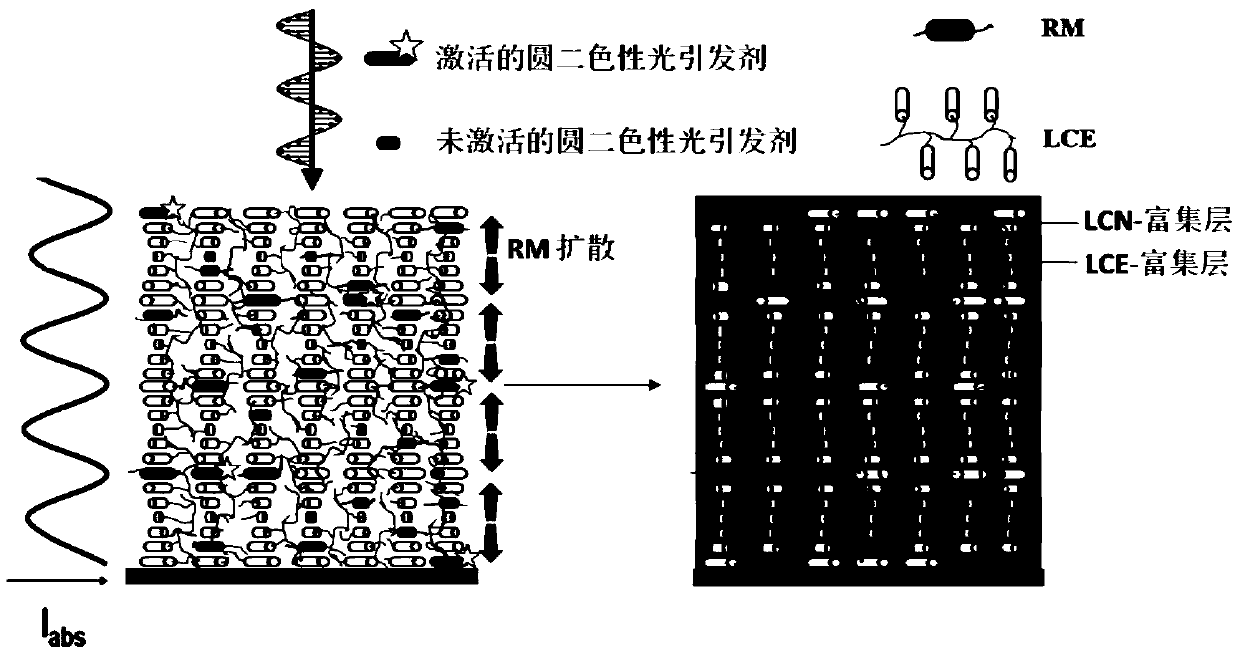

[0033] This embodiment provides a layered optical structure based on a cholesteric liquid crystal polymer semi-interpenetrating network, which is prepared by the following steps:

[0034] S1. Weigh 77 parts by mass of liquid crystal elastomer, 21 parts by mass of polymerizable chiral liquid crystal monomer, 1 part by mass of photoinitiator and 1 part by mass of surfactant and mix to form a liquid crystal mixture, which is placed in a brown bottle, The brown bottle was heated to 60° C. while stirring at a speed of 40 r / s to transform the liquid crystal material mixture into an isotropic liquid crystal mixture. Choose a black PET substrate, and prepare a layer of uniform liquid crystal mixture coating on the substrate by scraping the liquid crystal mixture material, with a thickness of about 25 microns;

[0035] S2. Use linearly polarized ultraviolet light to irradiate the liquid crystal mixture coating for 1 minute along the direction perpendicular to the substrate and scrape c...

Embodiment 2

[0039] This example provides a patterned film 1. The preparation process is the same as that of Example 1, except that the thickness of the liquid crystal mixture coating is 22 μm. "TU / e" mask, and then remove the mask to proceed to step S3.

[0040] This embodiment also provides a second patterned film, the preparation process of which is the same as that of the first patterned film, except that the coating thickness of the liquid crystal mixture is 11 μm.

[0041] A patterned film whose reflective properties depend on the polarization of incident light can be obtained after the first step of exposure through linearly polarized light plus a patterned mask. In this example we used a pattern with the letters "TU / e". After the first exposure step, the entire coating was fully polymerized by exposing it to unpolarized UV light, thereby obtaining a layered, cholesteric A monogram pattern of cholesteric phase material, and a surrounding background of non-layered, cholesteric phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com