Tunneling machine heavy-load hobbing cutter ring

A technology of tunnel boring machine and cutter ring, which is applied to furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of reducing the cracking probability of the hob cutter ring, increasing the diameter of the cutter ring, and increasing the thrust, so as to reduce the working cost and the thrust. The effect of large and prolonging the life of the hob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

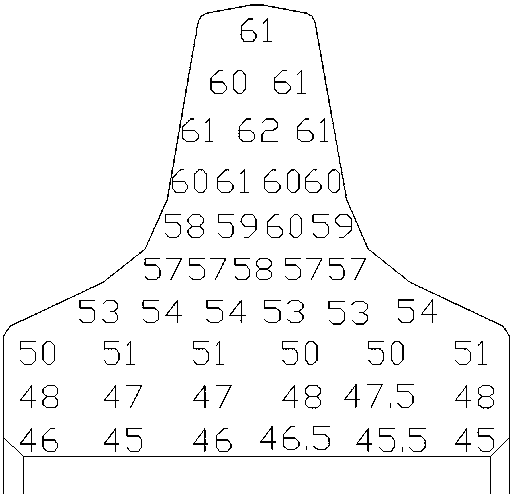

[0018] The present invention has been tested through experiments, and the inner diameter is sampled for impact test to reach 30J / cm 2 The above is 3 times of the overall quenching impact toughness of the cutter ring. The wear resistance of the cutter ring edge is not affected. The function of preventing the microcracks formed on the surface from extending to the inner diameter.

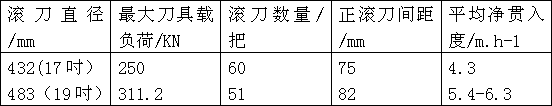

[0019] Due to the use of heavy-duty bearings, the load-bearing capacity of the bearings is increased. Taking 17-inch and 19-inch hobs as an example, the working load capacity of hobs is about 250-311KN. After testing, the load-bearing capacity of 21-inch heavy-duty hobs should reach more than 350KN.

[0020] According to the comparative test data of the site test, the main mechanical parameters of the two diameter hobs are mainly type II and III rocks:

[0021]

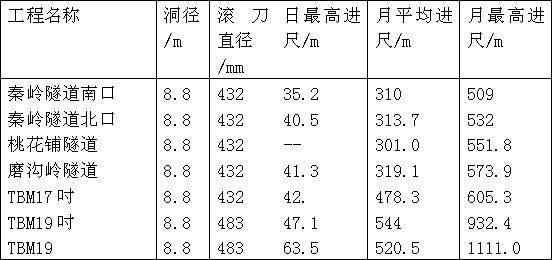

[0022] Construction site 1. Comparison of tunneling speeds of previous similar projects in the TBM tender section of Dahuofang

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com