Nucleating agent used for improving graphite form in gray pig iron and preparing process thereof

A preparation process and inoculant technology, which is applied in the field of inoculants for improving the graphite form in gray cast iron, can solve problems such as restricted inoculation, limited sulfur and oxygen content, and decreased strength and toughness of castings, so as to improve performance and reduce cross section The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

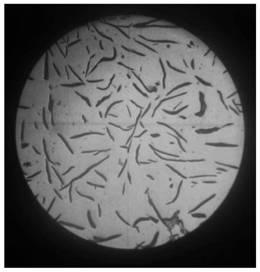

Image

Examples

Embodiment 1

[0055] An inoculant for improving the morphology of graphite in gray cast iron, the raw materials of the inoculant are configured according to the following weight ratios:

[0056] Ferrosilicon 74.1kg

[0057] Rare earth ferrosilicon 22.8kg

[0058] Calcium silicon barium 13.68kg

[0059] Silicon zirconium 3.42kg.

[0060] The preparation process of the inoculant for improving the graphite form in gray cast iron, the raw materials of the inoculant are prepared according to the above weight ratio according to the following steps:

[0061] 1) Control the contents of Si, Re, Ba, Zr and Ca in the inoculant:

[0062] Si: 64.3%

[0063] Re: 6.0%

[0064] Ba: 3.6%

[0065] Zr: 1.0%

[0066] Ca: 1.6%.

[0067] 2) According to the weight ratio, take 74.1kg of ferrosilicon, 22.8kg of rare earth ferrosilicon, 13.68kg of silicon-barium-calcium, and 3.42kg of silicon-zirconium four raw materials, dry them, and crush them into particles with a diameter of 1mm;

[0068] 3), put the ...

Embodiment 2

[0080] An inoculant for improving the morphology of graphite in gray cast iron, the raw materials of the inoculant are configured according to the following weight ratios:

[0081] Ferrosilicon 129.98kg

[0082] Rare earth ferrosilicon 34.92kg

[0083] Silicon barium calcium 19.4kg

[0084] Silicon zirconium 9.7kg.

[0085] In the preparation process of the inoculant for improving the graphite form in gray cast iron, the raw materials are prepared according to the above weight ratios according to the following steps:

[0086] 1) Control the contents of Si, Re, Ba, Zr and Ca in the inoculant:

[0087] Si: 64.74%

[0088] Re: 5.4%

[0089] Ba: 3%

[0090] Zr: 1.5%

[0091] Ca: 1.5%.

[0092] 2) According to the weight ratio, take 129.98kg of ferrosilicon, 34.92kg of rare earth ferrosilicon, 19.4kg of silicon-barium-calcium, and 9.7kg of silicon-zirconium four raw materials, dry them, and grind them into uniform particles with a diameter of 2mm;

[0093] 3), above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com