Efficient immobilized enzyme column and preparation method and application thereof

An immobilized enzyme, high-efficiency technology, applied in the direction of immobilization on or in the inorganic carrier, immobilized on/in the organic carrier, etc., can solve the incompatibility of rapid material transport and high surface activity, single pore size distribution, and porous Inconvenient use of materials, etc., to achieve the effect of reducing the reaction time of enzymolysis, low gelling temperature, and easy absorption and infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

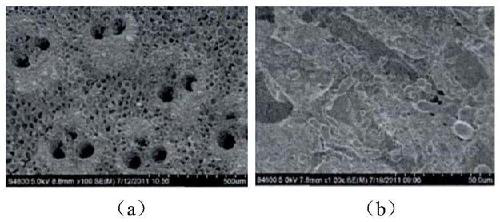

Image

Examples

Embodiment 1

[0040] Embodiment 1: Prepare the immobilized enzyme column according to the following method:

[0041] 1. Raw material preparation and prefabrication

[0042] The raw material of the liquid substrate is fresh milk, the viscosity at 37°C is 2.5 centipoise, and the active biological enzyme adopts lactase to hydrolyze the lactose in the fresh milk.

[0043] Weigh the agarose dry powder, the balance is pure water, add the agarose dry powder into pure water and mix well, heat to 90°C and mix well, keep warm at 60°C for later use, and prepare agarose solution with a final concentration of 0.05wt% according to the above method And final concentration 1.0wt% agarose solution;

[0044] 2. Preparation of high-efficiency immobilized enzyme column:

[0045] (1) Take 3 to 5-year-old moso bamboo trunks as raw materials, raise the temperature at 6°C / min to a carbonization temperature of 700°C under a nitrogen atmosphere, and heat-preserve and carbonize for 2 hours to obtain a bamboo charco...

Embodiment 2

[0055] Embodiment 2: Prepare the immobilized enzyme column according to the following method:

[0056] 1. Raw material preparation and prefabrication

[0057] The raw material of the liquid substrate is chemically pure olive oil with a viscosity of 80 centipoise at 30°C. The active biological enzyme adopts fat triglyceride lipase to hydrolyze the ester bonds in the olive oil.

[0058] Weigh agarose dry powder, 1wt% PEG6000, and the balance is pure water. Add the agarose dry powder into pure water and mix well, heat to 90°C and mix well, keep warm at 70°C for later use, and prepare the final concentration of 0.3 wt% agarose solution and final concentration 1.5wt% agarose solution;

[0059] When preparing the agarose solution, add PEG4000 or PEG6000 as a porogen;

[0060] 2. Preparation of high-efficiency immobilized enzyme column:

[0061] (1) Take aged grass stalks of Imperata cottage as raw material, raise the temperature to carbonization temperature of 900°C at 9°C / min un...

Embodiment 3

[0072] Embodiment 3: Prepare the immobilized enzyme column according to the following method:

[0073] 1. Raw material preparation and prefabrication

[0074] The raw material of the liquid substrate is a soluble starch solution, and the viscosity is adjusted to 60 centipoise with pure water at 30°C. The active biological enzyme uses α-amylase to hydrolyze the starch to generate glucose and maltose.

[0075] Weigh agarose dry powder, 2wt% PEG4000, and the balance is pure water, add the agarose dry powder into pure water and mix well, heat to 90°C and mix well, keep warm at 65°C for later use, and prepare 0.17wt% by the above method Agarose solution and 1.25wt% agarose solution;

[0076] 2. Preparation of high-efficiency immobilized enzyme column:

[0077] (1) Take Chinese fir peeled wood as a raw material, heat up to a carbonization temperature of 800° C. at 7.5° C. / min under a nitrogen atmosphere, and heat-preserve and carbonize for 2 hours to obtain a charcoal porous carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com