Daqu liquor making method and yeast manufacturing method

A production method and technology for Daqu liquor, applied in the field of winemaking, can solve the problems of low quality of Daqu, low yield of Luzhou-flavor Daqu liquor, low fermentation power and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

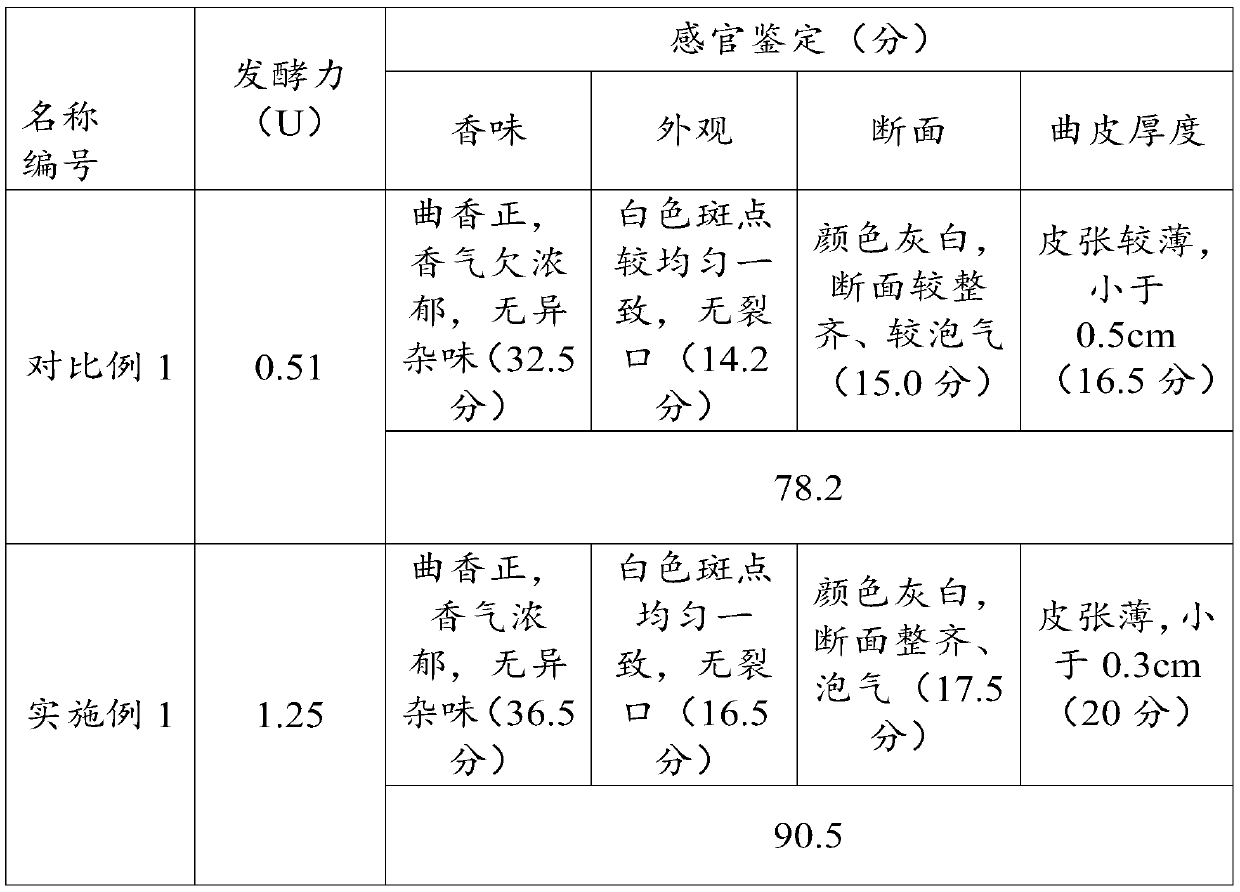

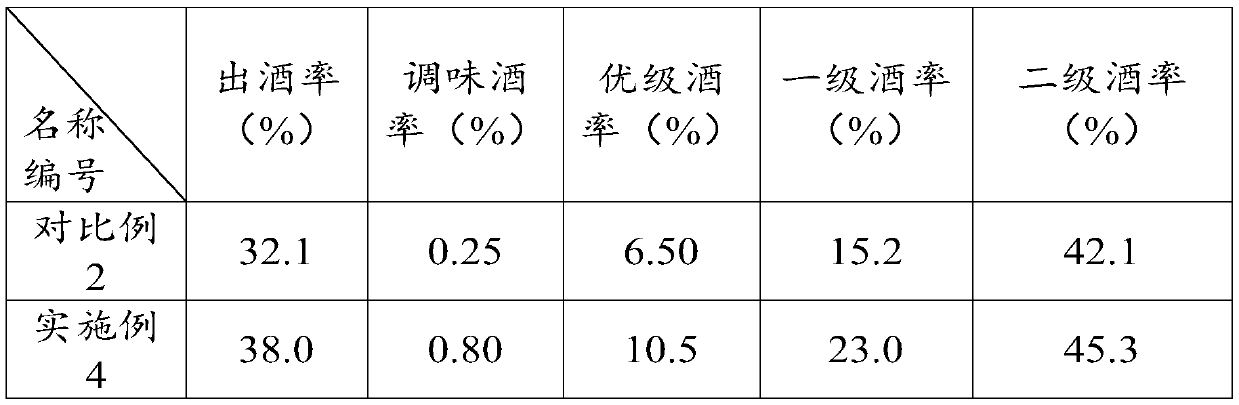

Examples

Embodiment 1

[0061] The present embodiment provides a kind of cultivating process of Daqu, which mainly includes the following steps:

[0062] Mix the medium-temperature koji with a storage period of 3 months and the medium-temperature koji with a storage period of 9 months in a ratio of 1:1.

[0063] The temperature in the culture room was detected at 8°C, and the mixed koji powder was mixed at 1.0kg / 100m 1 day before Daqu entered the room. 3 Spread evenly in the workshop.

[0064] Take the wheat, determine the amount of moistening water according to the dryness and humidity of the wheat, and determine the moistening temperature according to the season: the amount of moistening water accounts for 4% of the weight of the wheat; hot water above 85°C is used for moistening the grain, and the time for moistening the grain is about 20 hours. First pour the wheat on the grain moistening field, then turn it over and pile it up while sprinkling water, and clean out the impurities in the wheat (s...

Embodiment 2

[0074] The present embodiment provides a kind of culture process of Daqu, the process provided by the present embodiment is the same as that of Example 1, the difference is:

[0075] Before the billet enters the room, mix the medium-temperature koji with a storage period of 3 months and the medium-temperature koji with a storage period of 9 months in a ratio of 1:1.2.

[0076] The temperature in the cultivation room was detected to be 12°C. One day before Daqu entered the room, the mixed koji powder was mixed at a rate of 0.8kg / 100m 3 Spread evenly in the workshop.

[0077] Carry out the curved billet and enter the room (cultivation room) again.

Embodiment 3

[0079] The present embodiment provides a kind of culture process of Daqu, the process provided by the present embodiment is the same as that of Example 1, the difference is:

[0080] Before the billet enters the room, mix the medium-temperature koji with a storage period of 100 days and the medium-temperature koji with a storage period of 280 days in a ratio of 1:1.2.

[0081] The temperature in the culture room was detected to be 18°C. One day before Daqu entered the room, the mixed koji powder was mixed at a rate of 0.6kg / 100m 3 Spread evenly in the workshop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com