Bamboo-wood fiber flame-retardant composite decorative plate and preparation method thereof

A bamboo-wood fiber and flame-retardant composite technology, which is applied in the field of sheet metal processing, can solve the problems of no flame-retardant function, increase the difficulty of fire extinguishing, and warp and deform the sheet, achieve simple and practical structural design, low price, and avoid warping and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are clearly and completely described below. Obviously, the embodiments described below are only part of the embodiments of the present invention. Not all examples. All other embodiments obtained by those skilled in the art based on the embodiments of the present invention belong to the protection scope of the present invention.

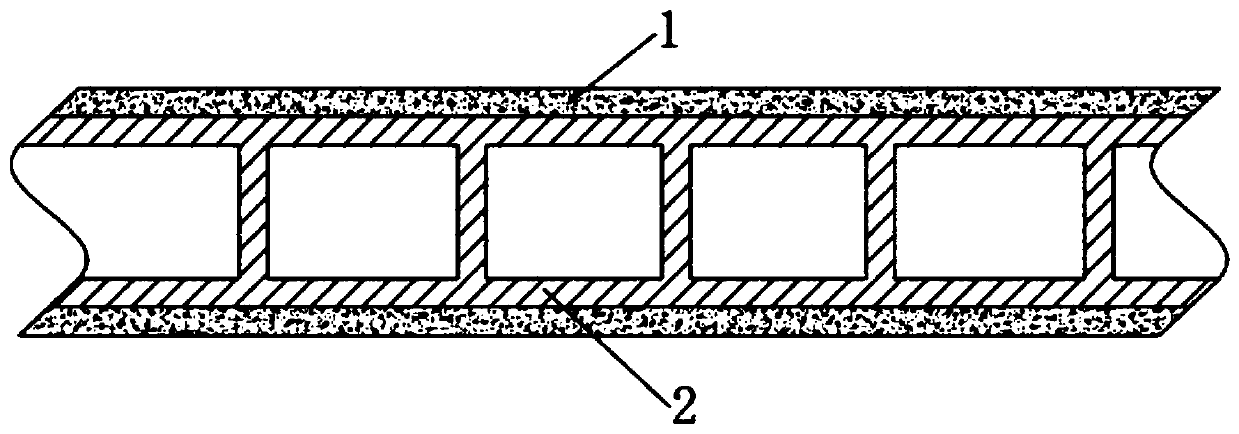

[0027] A kind of bamboo wood fiber flame-retardant composite decorative board, such as figure 1 As shown, including the middle foamed flame retardant board 2, the bamboo wood fiber flame retardant board 1 arranged on the upper and lower surfaces of the middle foamed flame retardant board 2;

[0028] The weight ratio of each raw material component in the middle foamed flame retardant board 2 is: PVC resin 59%, foaming agent 15%, foam regulator 8%, stabilizer 3%, fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com