Medical wastewater disinfection and sterilization treatment method

A technology of disinfection and sterilization and treatment methods, which is applied in the treatment of pathogenic microorganism wastewater, water/sewage treatment, water treatment with special compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

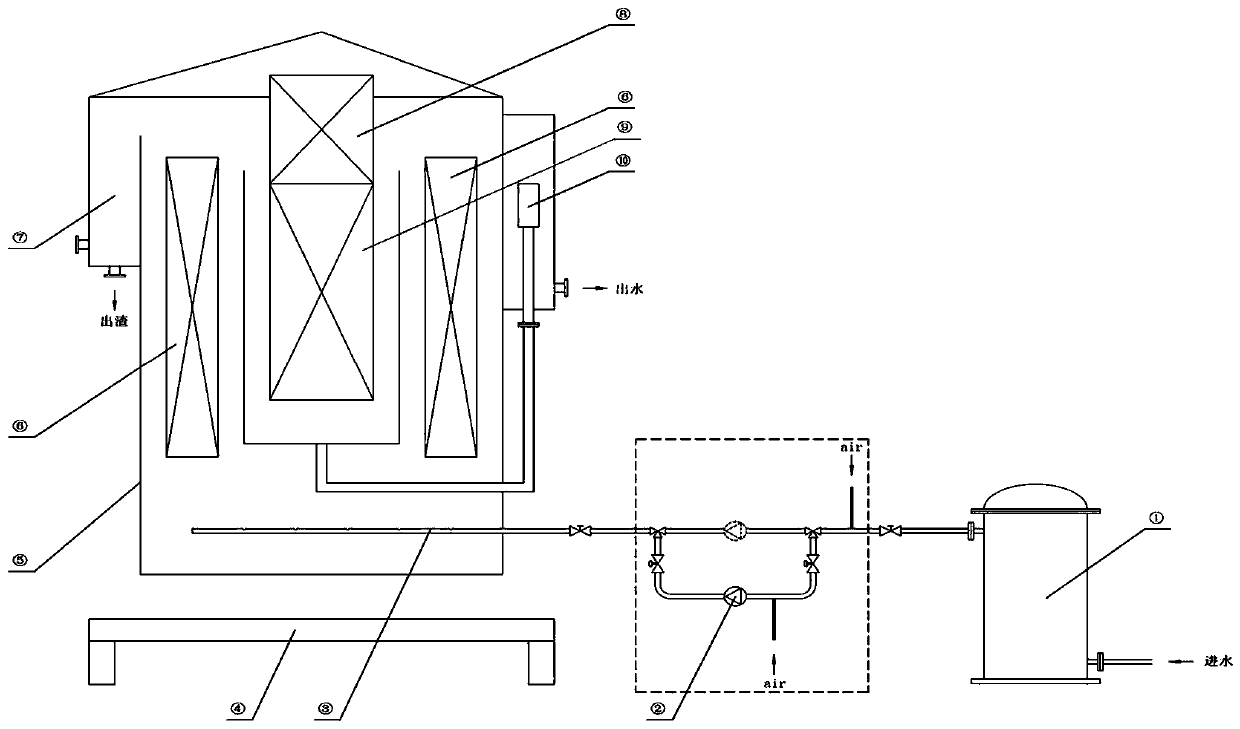

[0064] A kind of medical wastewater disinfection treatment method, based on such as figure 1 The medical wastewater disinfection and sterilization treatment device shown includes an instrument electric control box unit (not shown in the figure, those skilled in the art can make model selection and installation position according to needs), and the device also includes the following units:

[0065] Mechanical filter unit 1, the water inlet communicates with the outlet of the medical wastewater source (usually refers to the secondary sedimentation tank);

[0066] The dissolved air generating unit 2 is located downstream of the mechanical filter unit 1, and is used to raise the dissolved oxygen of the wastewater, and the inlet port is connected with the outlet of the mechanical filter unit 1;

[0067] The reactor unit includes a reactor shell 5 fixed on the transfer support unit 4,

[0068] The micro-nano bubble release and aeration unit 3 is located downstream of the dissolved ...

Embodiment 2

[0084] The medical wastewater disinfection and sterilization method based on the disinfection and sterilization device of the present invention, its steps are as follows:

[0085] Step S1, the effluent of the medical wastewater source (secondary sedimentation tank) enters the mechanical filtration unit to remove particles with a particle size ≥ 25 μm in the water and reduce the SS value of the water quality;

[0086] Step S2, all or part of the water treated in step S1 enters the dissolved air generating unit, and the dissolved air generating unit dissolves the self-inhaled air (oxygen or ozone) in the water under a certain pressure to increase the dissolved oxygen concentration of the water;

[0087] Step S3, introducing the pressurized dissolved air water treated with dissolved oxygen (ozone) in step S2 into the micro-nano bubble release and aeration unit in the reactor shell, and the dissolved air water is released by the micro-nano bubbles and decompressed by the aeration u...

Embodiment 3

[0091] The anode unit uses three-dimensional porous nano-TiO 2 The steps of the preparation process of the photocatalytic plate are as follows: S1: Fully coat the fixed bed base material with the water-based adhesive, take it out and let it dry naturally in a dust-free environment;

[0092] S2: The fixed bed base material after step S1 is air-dried is coated with photocatalyst; The fixed bed base material adopts three-dimensional structural nickel foam;

[0093] S3: After the photocatalyst coating process is completed, dry in a medium temperature oven at 250-300°C for 1.5h;

[0094] S4, repeat steps S2 and S31 times.

[0095] Specifically, the conditions of the dust-free environment in step S1 are: ambient temperature ≤ 22°C, ambient humidity ≤ RH55%, the coating amount is 0.2g / cm2, and the water-based adhesive is processed from the following raw materials in mass percentage: 28% ethyl orthosilicate, 21% dehydrated alcohol, 1% hydrochloric acid, the balance is deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com