Pipe loading or dumping conveyor

A conveyor and pipe technology, applied in the direction of lifting device, etc., can solve the problems of difficult to determine the center of gravity of the pipe, prone to deviation, casualties, etc., and achieve the effect of easy production, promotion and use, good stability, and protection and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

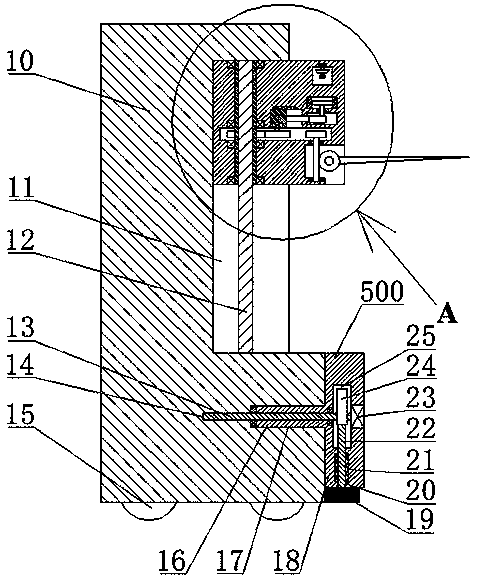

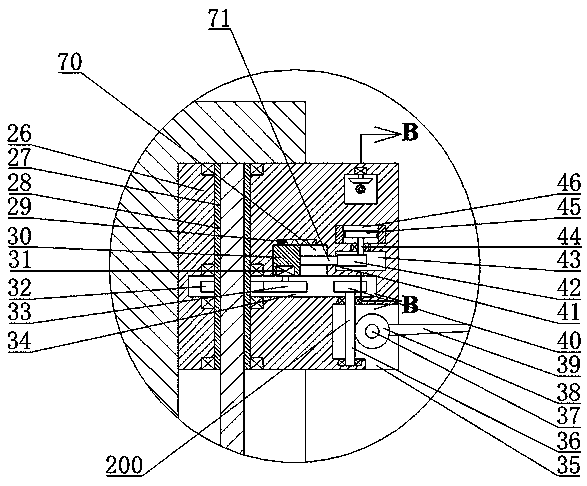

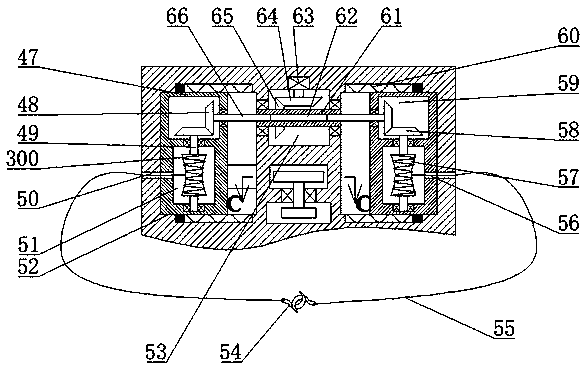

[0020] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] A pipe loading or dumping conveyor described in conjunction with accompanying drawings 1-4 includes a fuselage 10 and an operating chamber 11 provided in the fuselage 10, and a slide is provided in the operating chamber 11 that can slide up and down. The platform 26, the sliding platform 15 is provided with a switching cavity 34, the switching cavity 34 is rotatably provided with a threaded sleeve 27, and the threaded sleeve 27 is fixedly arranged around the operating cavity 11 and extends up and down. The threaded rod 12 rotates, because the first threaded rod 12 is threadedly connected in the first threaded hole 28 provided in the threaded sleeve 27 to drive the sliding platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com