A shot blasting equipment for rotating shot peening to treat vehicle parts

A technology of shot blasting treatment and vehicle, which is applied in the field of workpiece processing, can solve the problems of large processing volume and the inability of comprehensive shot blasting treatment of workpieces, etc., and achieve the effect of improving shot blasting effect, improving shot blasting effect and processing efficiency, and easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

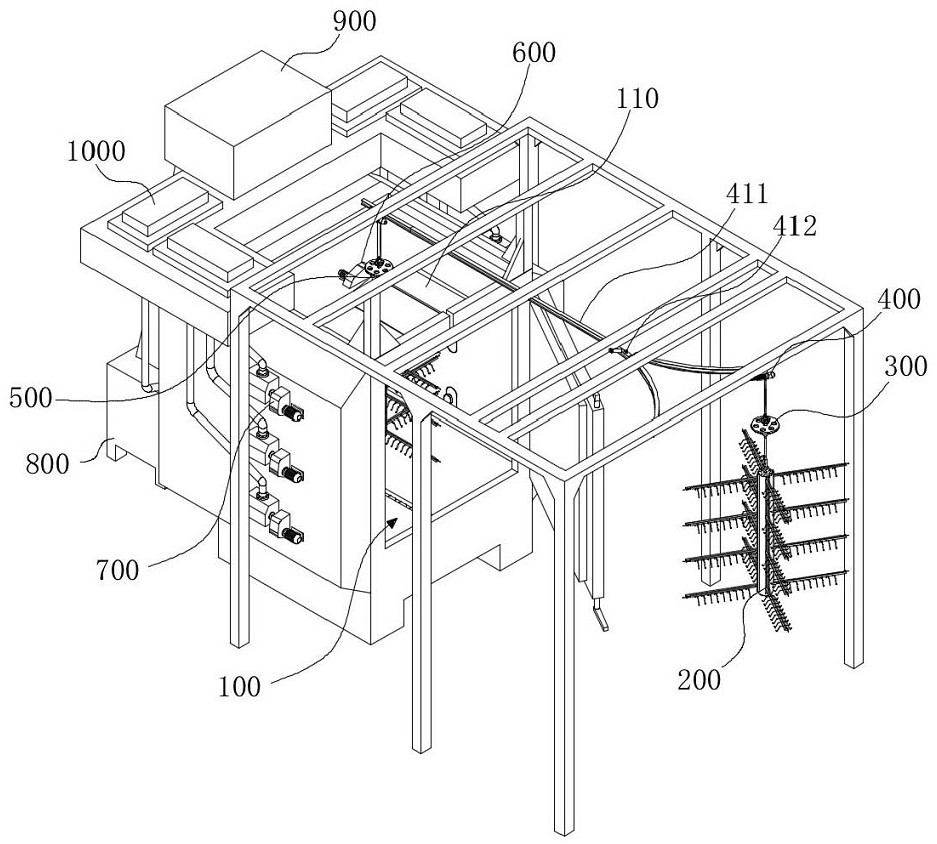

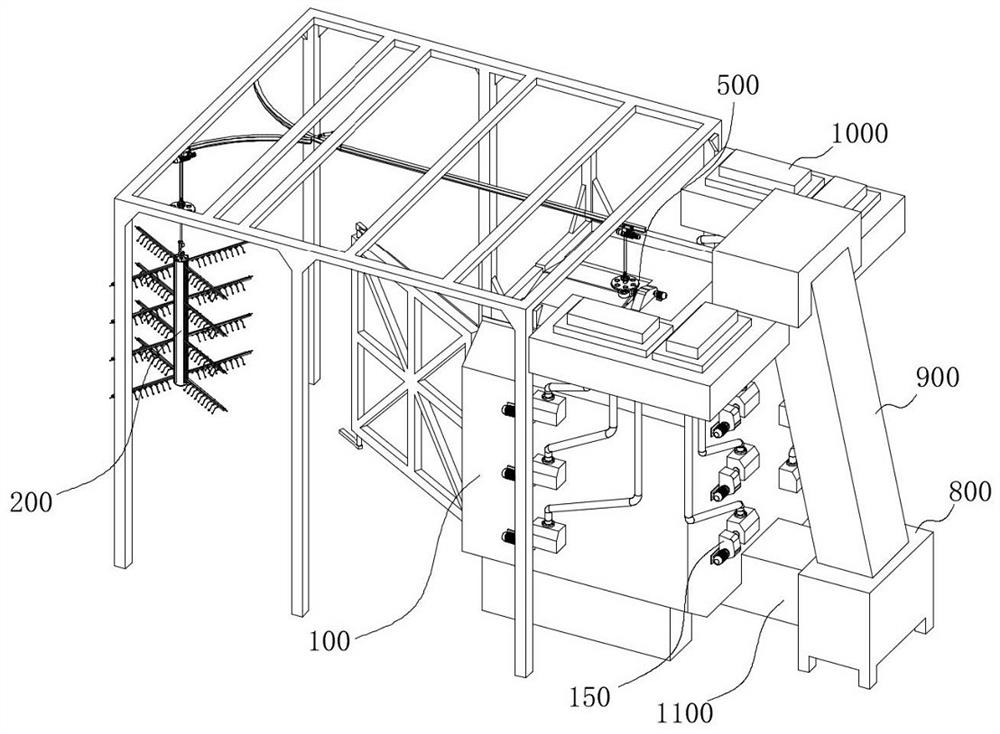

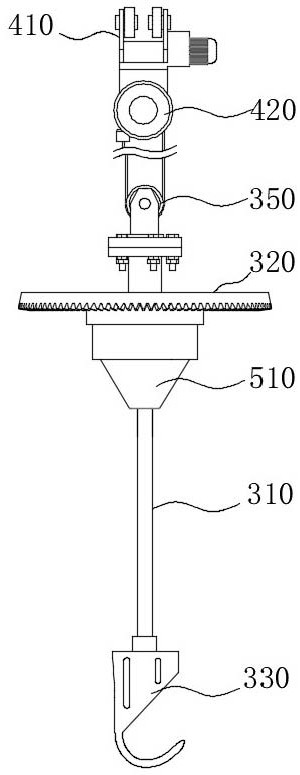

[0045] refer to figure 1 , 2 , 5-7, in the embodiment of the present invention, a kind of shot blasting equipment for rotating shot blasting treatment of vehicle parts is proposed, including a shot blasting treatment chamber 100, and the side wall of the shot blasting treatment chamber 100 is equipped with a A shot blasting unit for shot blasting, the shot blasting unit is connected with an adjustment mechanism 1200, and the adjustment mechanism 1200 is used to adjust the direction in which the shot blasting unit sprays shot sand.

[0046] Through the setting of the adjustment mechanism 1200, the direction in which the shot blasting unit sprays the shot sand can be adjusted, so that some irregular workpieces can also be effectively shot blasted.

[0047] The shot blasting unit 1200 includes sub-blasting sub-units, each sub-blasting blasting unit is arranged on the side wall of the shot blasting treatment chamber 100 at intervals up and down, and the adjustment mechanism 1200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com