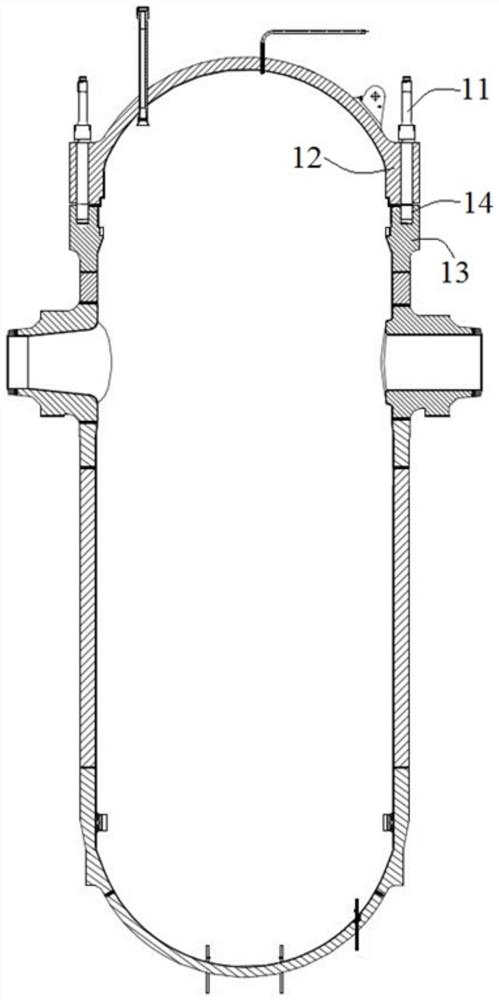

Damage repair method for main screw hole of reactor pressure vessel in nuclear power plant

A pressure vessel and damage repair technology, which is applied in the field of damage repair of main screw holes of reactor pressure vessels in nuclear power plants, can solve the problems of weakened rigidity of the flange structure of RPV vessels and excessively large size of main screw holes, and achieves application prospects and Huge economic benefits, the effect of repairing severe damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

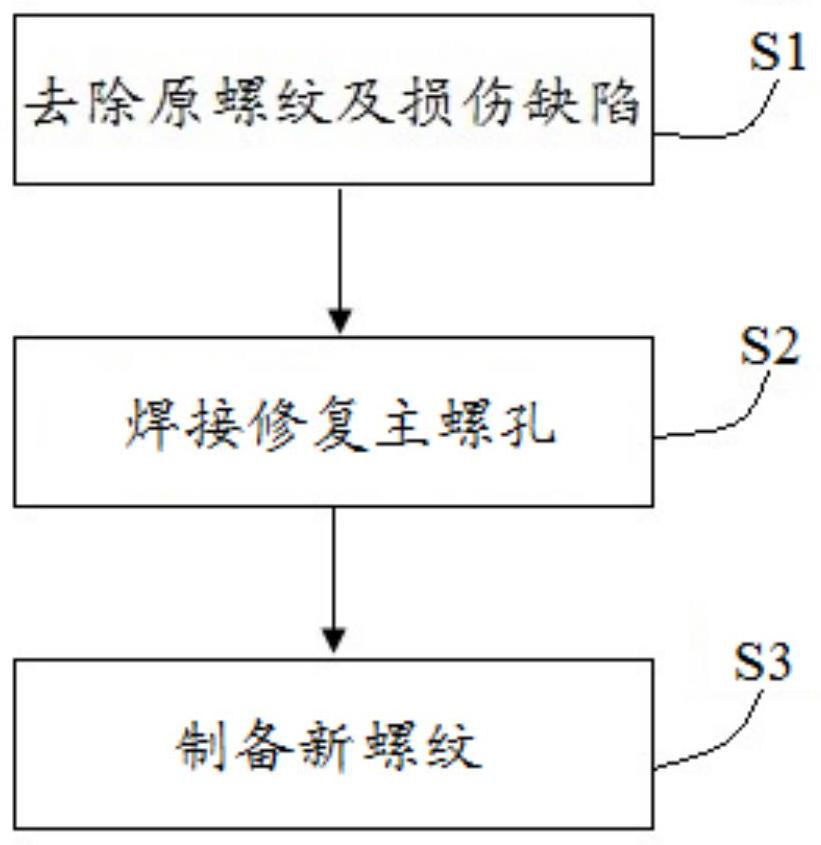

Method used

Image

Examples

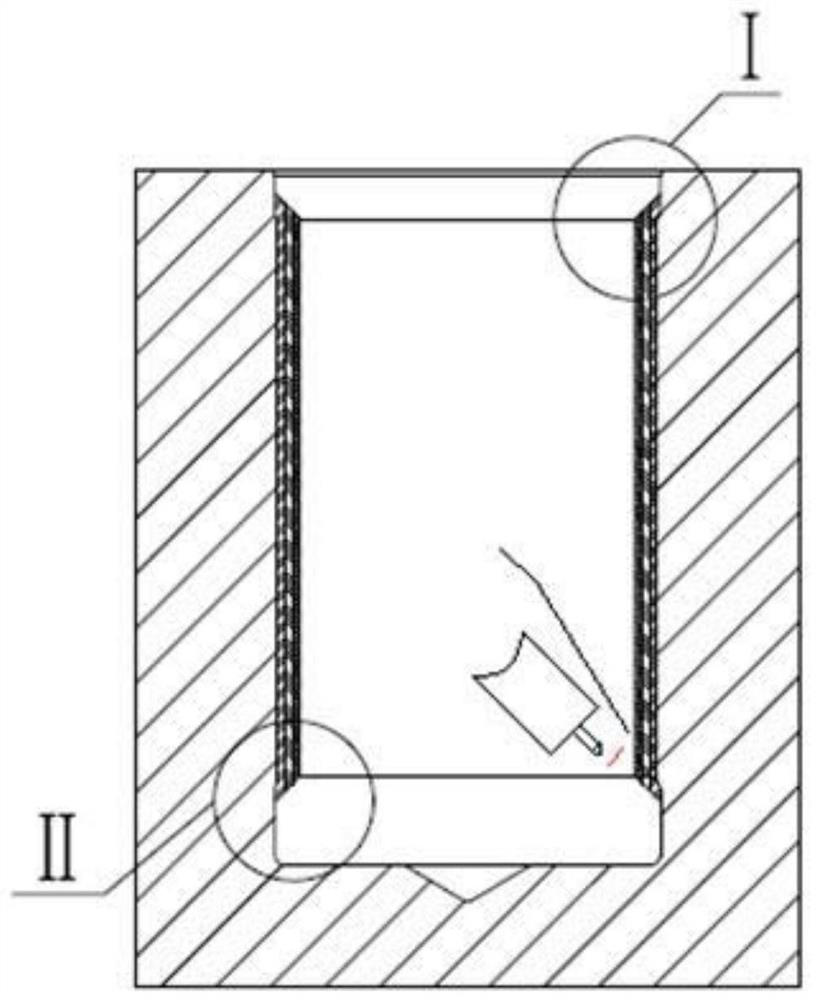

Embodiment Construction

[0031] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0032] Automatic pulse tungsten inert gas shielded welding (GTAW) is one of the methods with better welding quality in gas shielded arc welding in the world. During welding, the welding wire is fed by the wire feeding mechanism, and the welding torch automatically moves according to the set trajectory for welding. The shielding gas (argon, helium, etc.) is sprayed continuously from the nozzle of the welding torch, forming a gas shield around the molten pool to isolate the air. Compared with manual metal arc welding (SMAW) commonly used in nuclear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com